Argo HPL Manual

Other Argo Air Conditioner manuals

Argo

Argo AEI1G80EMX User manual

Argo

Argo POLIFEMO KIRK User manual

Argo

Argo ECOLIGHT PLUS 9000 UI Operating manual

Argo

Argo ADG ECO 35PH Operating manual

Argo

Argo FC52AL User manual

Argo

Argo ADIAS19DC User manual

Argo

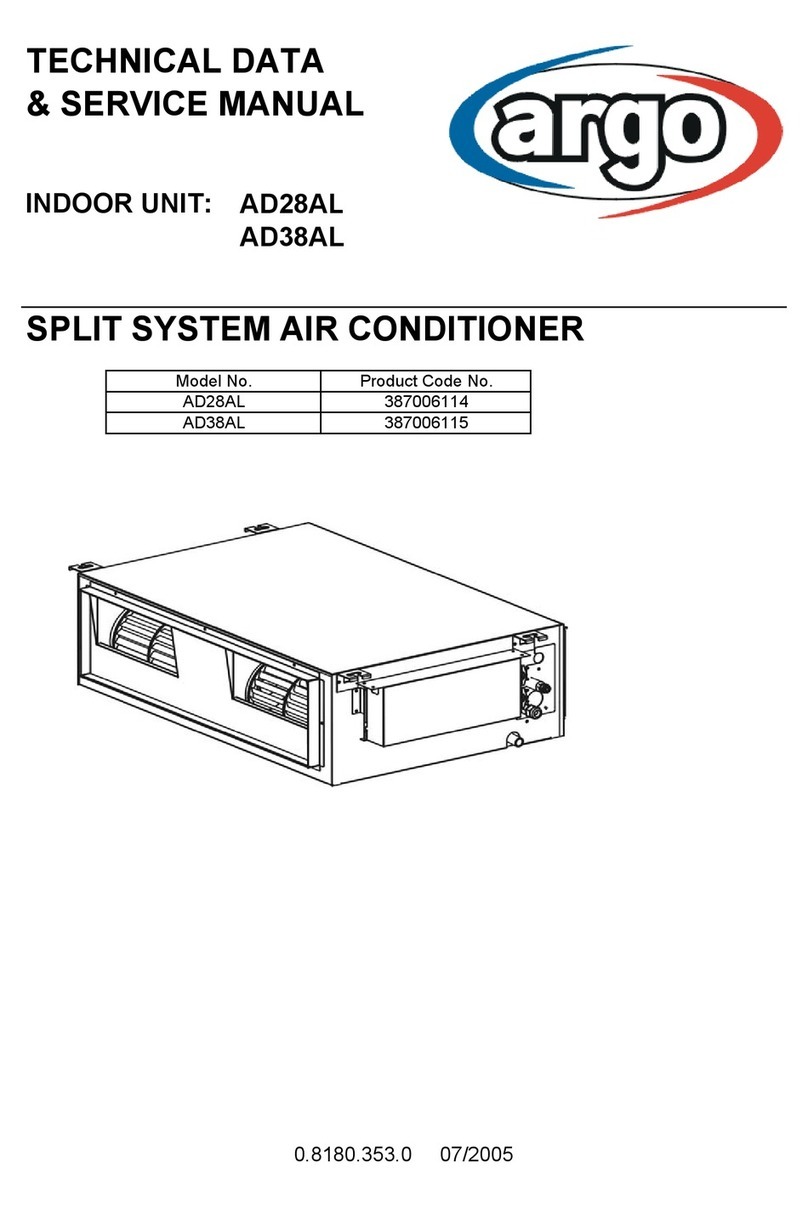

Argo AD28AL Manual

Argo

Argo AMG21SDT Manual

Argo

Argo Ecolight 9000 UI User manual

Argo

Argo dados 40 User manual

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual