PiCUS TreeQinetic Manual

2

1 Content

2Abreviations and Acknowledgements............................................................................. 4

3.1 Intended Use........................................................................................................... 4

3.2 Designated Application............................................................................................ 5

3.3 Disclaimer ............................................................................................................... 5

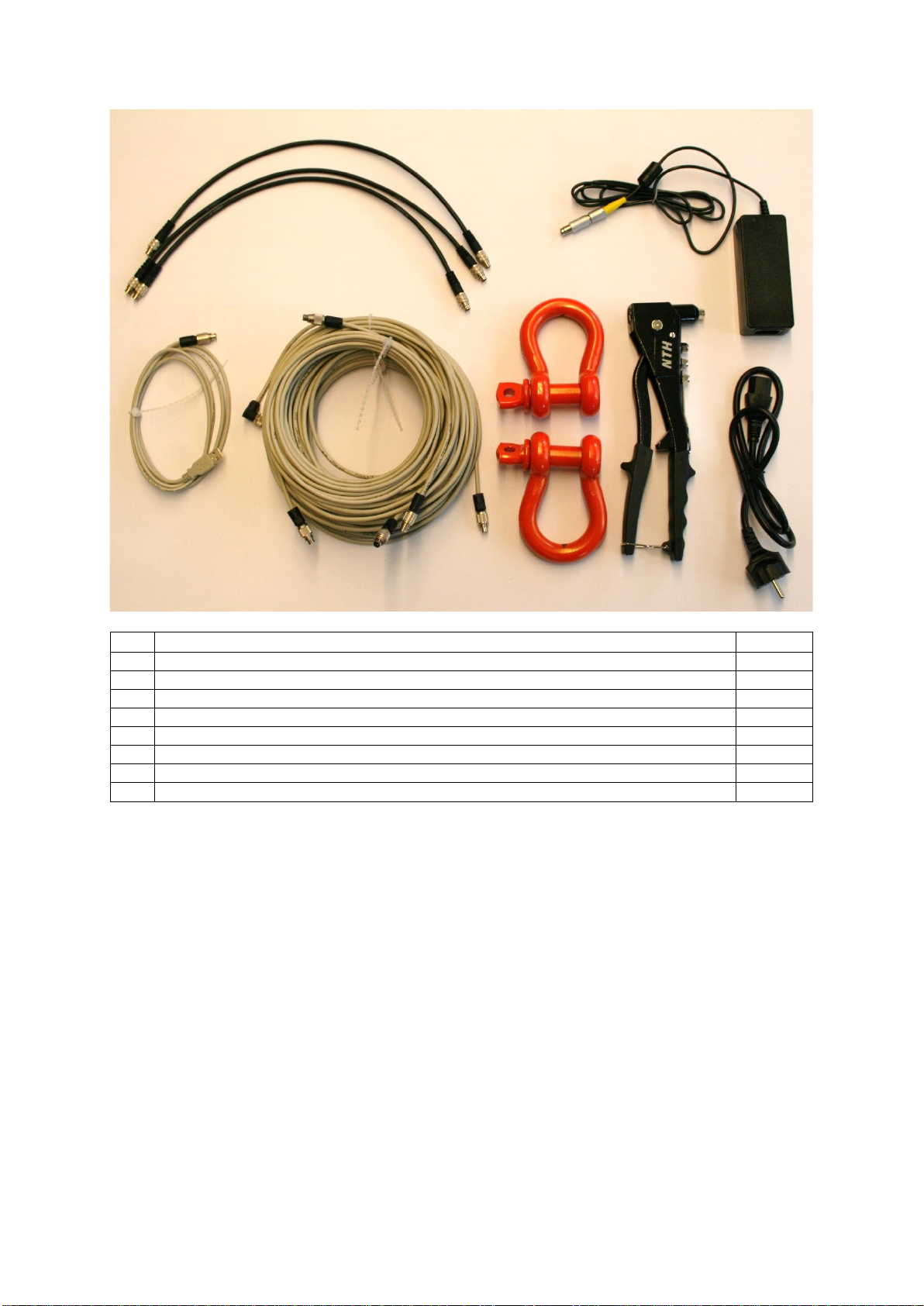

3.4 Packing List (Starter)............................................................................................... 6

4Measuring Instruments................................................................................................... 8

4.1 Description of System Components ........................................................................ 8

4.1.1 Communication Unit......................................................................................... 8

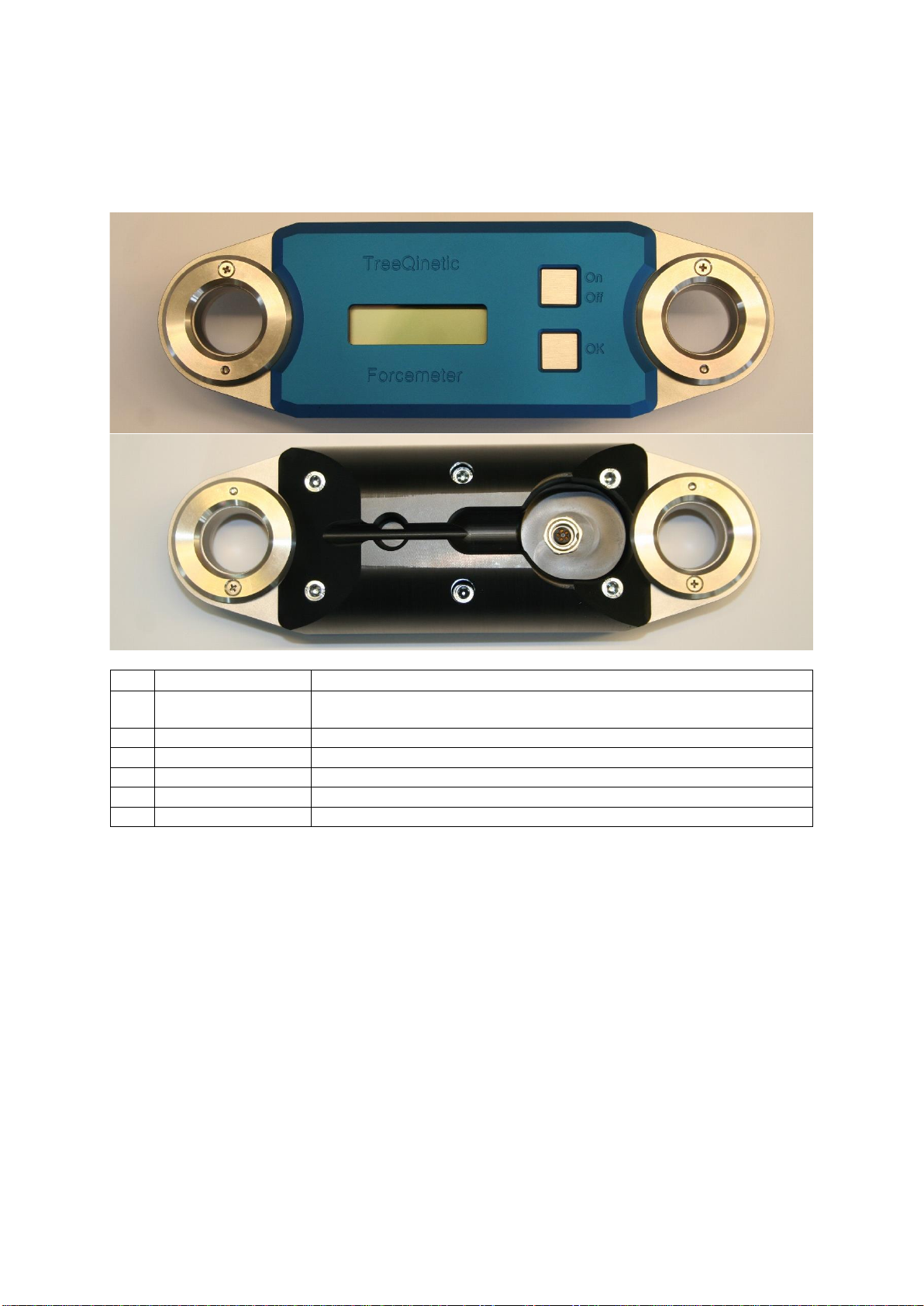

4.1.2 Forcemeter......................................................................................................10

4.1.3 Inclinometer ....................................................................................................11

4.1.4 Elastometer.....................................................................................................14

4.1.5 Overlaod Indicator...........................................................................................16

4.1.6 Cables.............................................................................................................17

4.1.7 Case ...............................................................................................................17

4.1.8 Eightfold Charger (Optional)............................................................................18

4.1.9 Anemometer (Optional)...................................................................................19

4.2 General Operating Instructions...............................................................................20

4.2.1 Ambient Conditions.........................................................................................20

4.2.2 Module Addresses ..........................................................................................20

4.2.3 Automatic switch-off........................................................................................21

4.2.4 Charging .........................................................................................................21

4.2.5 Maintenance ...................................................................................................22

4.2.6 Spread of Infestations .....................................................................................22

4.3 Calibration..............................................................................................................22

5App................................................................................................................................23

5.1 Installation..............................................................................................................23

5.2 Starting the App .....................................................................................................23

5.2.1 Permissions ....................................................................................................23

5.2.2 Features of Android.........................................................................................24

5.2.3 Features of iOS...............................................................................................24

5.3 Control Concept.....................................................................................................24

5.3.1 General...........................................................................................................24

5.3.2 Features of Android.........................................................................................25

5.3.3 Features of iOS...............................................................................................25

5.4 Tab –Control .........................................................................................................26

5.4.1 Page –Communication Unit............................................................................26

5.4.2 Page –Info......................................................................................................27

5.5 Tab –Project..........................................................................................................27

5.5.1 Page –Management.......................................................................................27