Argus Analyzers » CD Home » User Manual » Tester Setup Options

User Manual: AA360, AA1000

TESTER SETUP OPTIONS

There are a number of settings that may be modified to optimize functions for specific users and applications. These

settings are stored in memory and used in all future tests until the settings are again modified.

The tester must be connected to a battery during setup.

If you make a mistake, disconnect, re-connect and enter the SETUP mode again.

The printer does not need to be connected to the tester to complete any setup operation.

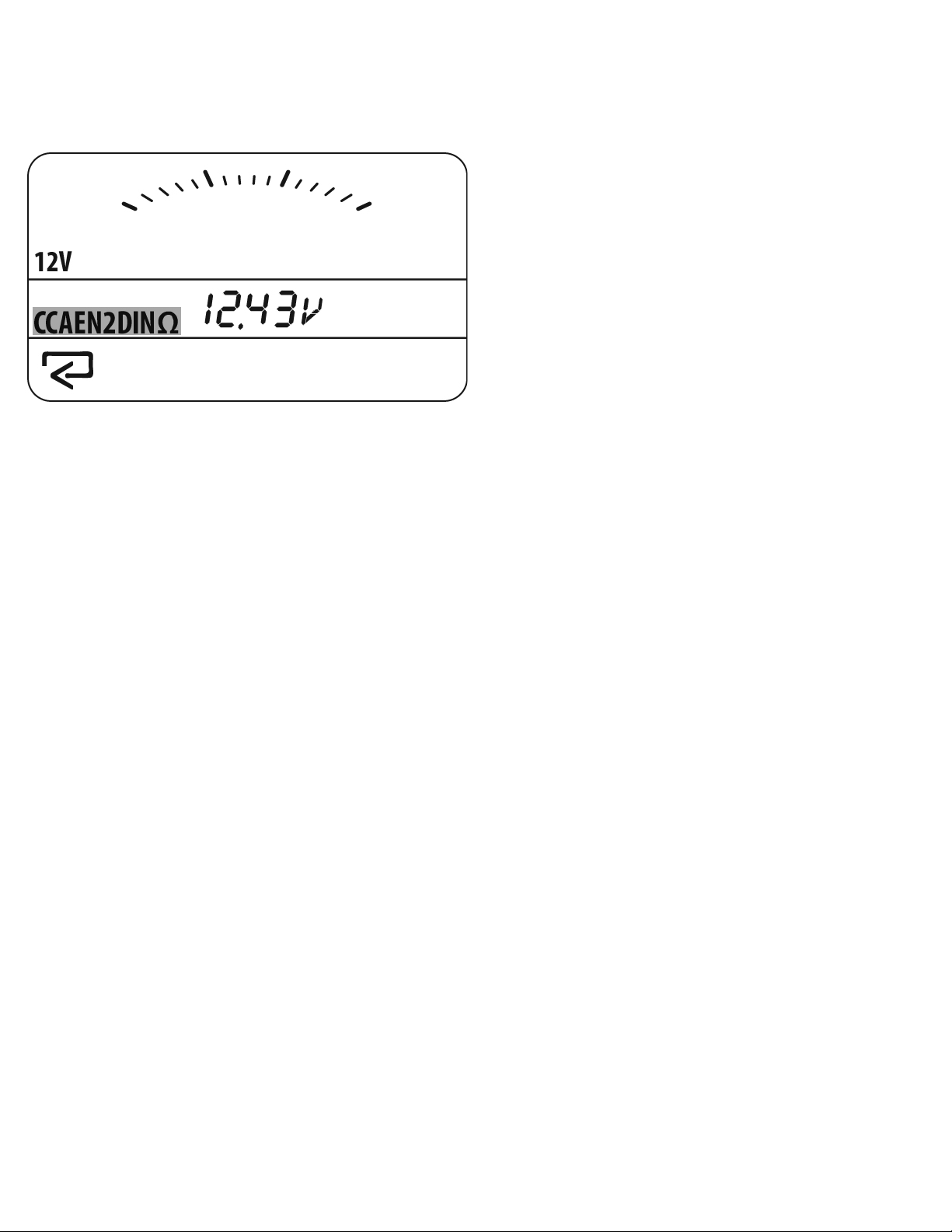

Enter SETUP mode

After completing a test, press [enter/print] button to change the display to the ‘SoC’ page. From the ‘SoC’ page, press

and hold [<] for 3 seconds (until beep). The display clears and the first setup page, ‘Prn’ is displayed. At each setup

page, change the value using [>] or [<], and confirm the value by pressing [enter/print]. After the last setup screen (P-

S), all setup values are stored and the tester returns to normal mode.

Each screen is identified at the top left of the display in order. Details for each SETUP page are below.

1. ‘Prn’ Set Printer language.

2. ‘Yr’ Set Year.

3. ‘Dat’. Date - set day first, then month.

4. ‘ti’. Time - set hours first, then minutes.

5. ‘Ey’. Easy test mode - select ‘On’ or ‘Off’

6. ‘P-F’. Pass / Fail mode – ‘On’ or ‘Off’.

7. ‘P-S’. Output mode - P=Print, S=Save. Select ‘P’ or ‘P-S’ or ‘S’.

Note: To skip any setup page without making any changes, press the [enter/print] to advance to the next page.

SETUP Page 1: ‘Prn’ Printer Language Selection

The AATPR20 can print in 22 languages. The default language is ENGLISH. On the ‘Prn’ page of the setup mode, use

the [<] and [>] buttons to select the number for desired language. Confirm the selection by pressing the [enter/print]

button.

1. English

2. French

3. German

4. Dutch

5. Spanish

6. Portuguese