Inficon Quantus LP100 User manual

OPERATING MANUAL

Quantus™LP100

Gas Analysis System

IPN 074-510-P1B

www.inficon.com [email protected]

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2011 INFICON

®

OPERATING MANUAL

Quantus™LP100

Gas Analysis System

IPN 074-510-P1B

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON®, FabGuard® and Quantus™ are trademarks of INFICON GmbH.

Oracle® and Java™ are registered trademarks of Oracle and/or its affiliates.

Windows®, is a registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2011 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

Warranty

www.inficon.com [email protected]

TOC - 1

IPN 074-510-P1B

Quantus LP100 Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Chapter 1

Introduction

1.1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.2 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.3 General Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.1 Returning Your Instrument to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Purpose of the Quantus LP100 Gas Analysis System . . . . . . . . . . . . . . . . . 1-5

1.6 Computer System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7 Operating System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8 Description of the Quantus LP100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8.2 LP100 Sensor Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.8.3 LP100 Microplasma Sensor Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.8.4 LP100 Electronic Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.9 AUX I/O Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1 Auxiliary I/O Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1.1 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1.2 Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1.2.1 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1.2.2 Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.1.2.3 Valve Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.9.2 Auxiliary I/O Pin Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.10 Quantus LP100 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

TOC - 2

IPN 074-510-P1B

Quantus LP100 Operating Manual

Chapter 2

Theory

2.1 Introduction to Optical Emission Spectroscopy . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Origin of Optical Emission Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Complex Optical Emission Spectra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 Increasing Numbers of Electrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.2 Molecular Combinations of Atoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Quantus and Optical Emission Spectroscopy . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3

Installation

3.1 Installation of the Quantus LP100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 LP100 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1.1 LP100 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Installation Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.4 Connecting the USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 LP100 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4

Operation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Sensor Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Descriptions of Sensor Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Spread-Spectrum (SS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Chapter 5

Accessories and Spare Parts

5.1 LP100 Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 LP100 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 USB to Ethernet Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.2 Isolation Valve Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6

Maintenance

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Replacing the Microplasma Sensor Cell (MSC) . . . . . . . . . . . . . . . . . . . . . . 6-1

1 - 1

IPN 074-510-P1B

Quantus LP100 Operating Manual

Chapter 1

Introduction

1.1 System Overview

INFICON Quantus™LP100 gas analysis system operates using the principal of

optical emission spectroscopy. A gas sample or gas-flow of interest is presented to

a proprietary Microplasma Sensor Cell inside the sensor that excites the gas,

causing it to produce a plasma. The light emitted by the plasma has a spectrum

that provides information about the atoms and molecules present. The optical

emission is detected by a spectrometer inside the sensor. The resulting spectra are

analyzed by INFICON FabGuard™analysis software on a control computer.

1.2 Safety

The LP100 generates high voltages, radio-frequency signals, and light (ultra-violet,

visible, and infrared light). Aside from a field-replaceable Microplasma Sensor Cell,

the LP100 has no user-serviceable parts.

WARNING

To prevent injury, and to prevent voiding the factory

warranty, repairs to the LP100 should only be performed

by factory-authorized personnel.

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and

WARNINGS found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum instrument

efficiency when followed.

CAUTION

Failure to heed these messages could result in damage

to the instrument.

WARNING

Failure to heed these messages could result in personal

injury.

1 - 2

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.2.2 Before You Begin

1REVIEW the installation process thoroughly before beginning work.

2CONFIRM that the sensor materials of construction and surfaces are

compatible with the exposed process environment.

3CONFIRM that the sensor is installed in an approved manner.

1.2.3 General Warnings and Cautions

WARNING

NEVER operate the sensor without its protective

enclosures. The sensor should only be powered when

fully mounted using the KF vacuum flange interface to an

appropriate system to be monitored.

WARNING

NEVER install or power the sensor in a position where a

user can physically access, or view directly the

microplasma.

WARNING

NEVER touch the microplasma source or its assembly

within its containment cavity.

WARNING

NEVER view directly the microplasma discharge.

CAUTION

NEVER operate the sensor when the interior of the

microplasma sensor cell is exposed to ambient or other

sources of light such as other processes.

1 - 3

IPN 074-510-P1B

Quantus LP100 Operating Manual

CAUTION

NEVER prevent airflow by blocking the vent holes or the

cooling fan on the sensor. Unpredictable results or

damage to the sensor may result.

CAUTION

NEVER power the sensor with an unapproved power

supply.

1.3 Terminology

In describing the use of the sensor in this guide, the following terms will be used:

Sensor: A complete LP100 sensor that includes an Electronic Control Module

(ECM) and Microplasma Sensor Cell (MSC).

Electronic Control Module (ECM): The ECM contains a spectrometer and

electronics. This unit is powered by a 24 V (dc) 2.5 A supply.

Microplasma Sensor Cell (MSC): The MSC contains the microplasma light

source. The MSC is field-replaceable.

Software: Quantus is operated by INFICON FabGuard analysis software running

on an INFICON FabGuard Controller or Windows®-based PC.

Controller: The computer running INFICON FabGuard analysis software to

operate Quantus is an INFICON FabGuard Controller or Windows-based PC.

Tool or Process Tool: A process tool or other system onto which the sensor is

attached. The sensor should only be used when properly installed onto an

appropriate vacuum system or process tool.

1 - 4

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.4 How To Contact Customer Support

Worldwide support information regarding:

Technical Support, to contact an applications engineer with questions

regarding INFICON products and applications, or

Sales and Customer Service, to contact the INFICON Sales office nearest you,

or

Repair Service, to contact the INFICON Service Center nearest you,

is available at www.inficon.com.

If you are experiencing a problem with your instrument, please have the following

information readily available:

the serial number for your instrument,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

To contact Customer Support, see Support at www.inficon.com.

1.4.1 Returning Your Instrument to INFICON

Do not return any component of your instrument to INFICON without first speaking

with a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your

instrument.

Prior to being given an RMA number, you will be required to complete a Declaration

Of Contamination (DOC) form to identify what process materials your instrument

has been exposed. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the instrument be sent to a

designated decontamination facility, not to the factory.

1 - 5

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.5 Purpose of the Quantus LP100 Gas Analysis System

The Quantus LP100 detects changes in gas characteristics such as composition,

pressure or concentration. Detecting such changes allows the user to detect leaks,

contaminants and process endpoints in critical process environments.

1.6 Computer System Requirements

The Quantus gas analysis system utilizes INFICON FabGuard analysis software

with the following computer system requirements.

1.7 Operating System Requirements

INFICON FabGuard analysis software requires Windows XP Operating System or

higher.

Quantus requires the Java™Runtime Engine, Version 6. Many computers already

have the Java Runtime Engine installed. If necessary, the Java Runtime Engine

can be downloaded from www.java.com. Note that 32-bit operating systems

require the 32-bit Java Runtime Engine, while 64-bit operating systems require the

64-bit Java Runtime Engine.

1.8 Description of the Quantus LP100

1.8.1 Introduction

The INFICON Quantus LP100 gas analysis system is designed for monitoring

changes in gas composition over the pressure range of 10 mTorr to 1 Torr, including

many corrosive gas environments. In some cases, the LP100 may function beyond

this pressure range. However, the ability to ignite plasma may be affected by the

species of gas present. Therefore, the pressure range for plasma ignition, or for

sustaining the plasma, may be greater or lesser depending on the application. For

application specific support, please contact your nearest INFICON representative.

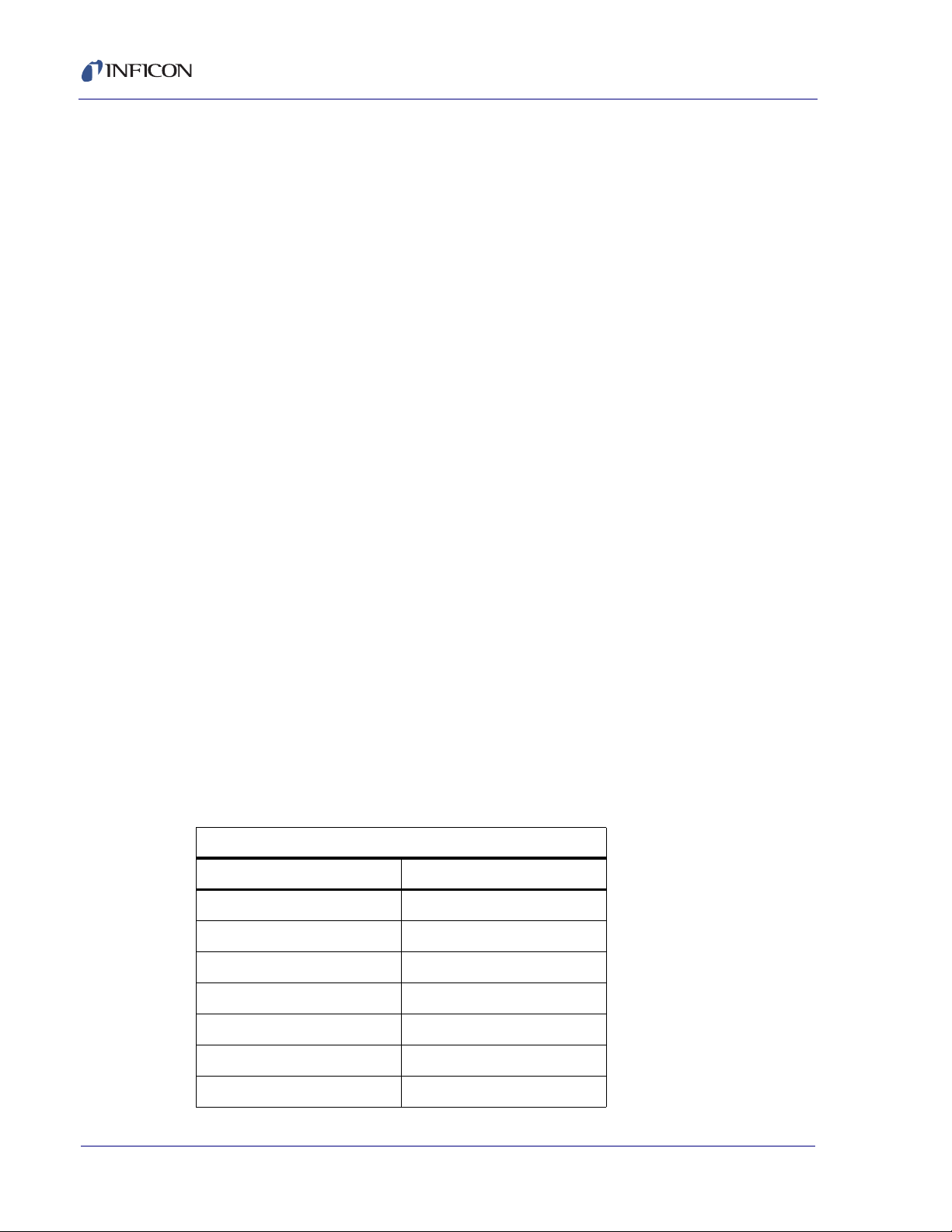

Table 1-1 Computer System Requirements

Minimum Requirement Recommended

Processor Intel Pentium 4, 3 GHz Intel Core 2 or greater

Memory 1 GB 2 GB or greater

Hard Drive 80 GB 160 GB or greater

Resolution 15" (1024 x 768) 17" (1280 x 1024)

1 - 6

IPN 074-510-P1B

Quantus LP100 Operating Manual

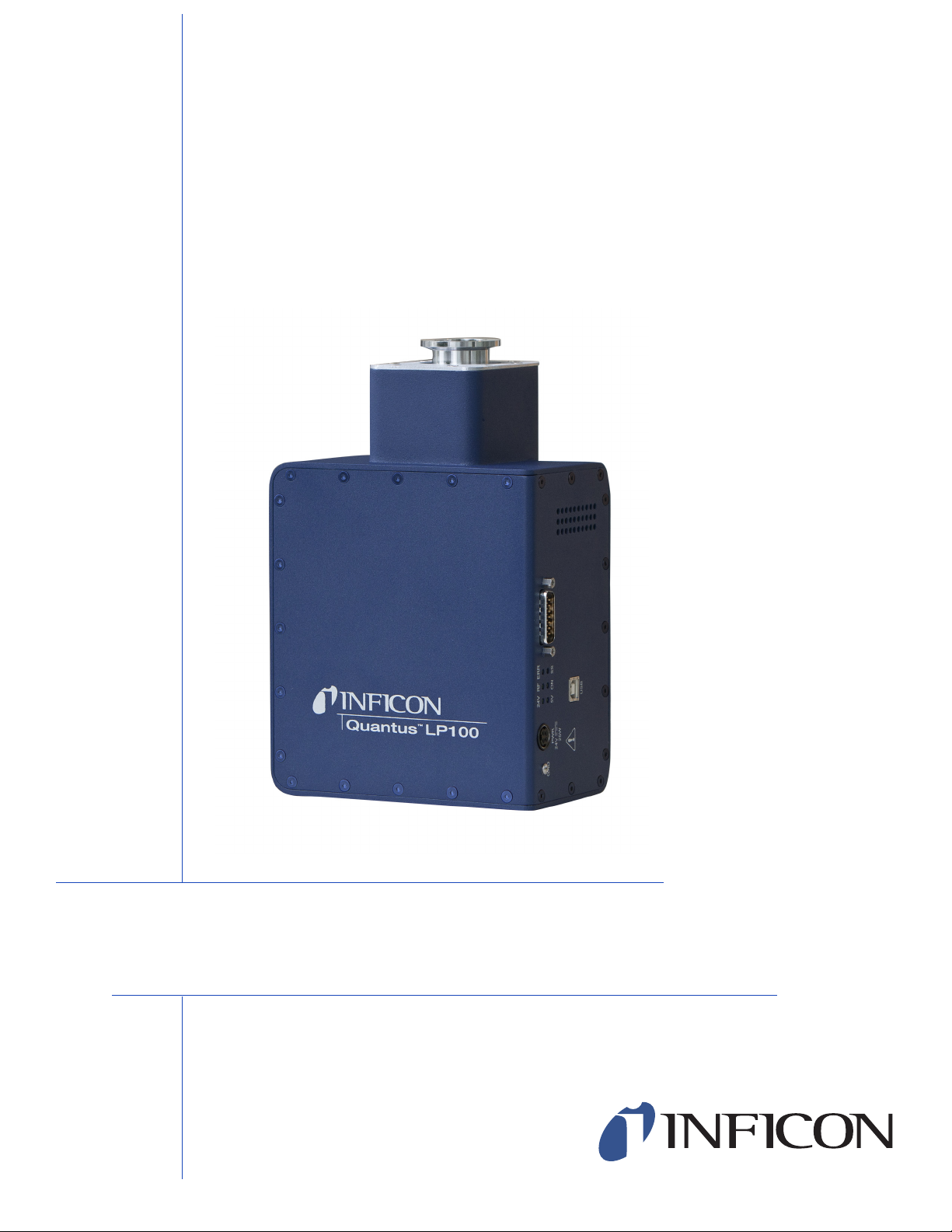

1.8.2 LP100 Sensor Overview

The LP100 (Figure 1-1) is designed for applications that operate between 0.01 and

1 Torr. Exact pressure range is application dependent. Range of 0.01 to 1 Torr is

tested with argon. The LP100 is designed and manufactured to withstand exposure

to corrosive and aggressive gases such as Chlorine, Fluorine and other chemicals.

The LP100 has two main sections, an Electronic Control Module (ECM) and a

Microplasma Sensor Cell (MSC). The ECM occupies the larger portion of the

housing while the MSC occupies the smaller portion of the housing.

Figure 1-1 LP100

1 - 7

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.8.3 LP100 Microplasma Sensor Cell

Figure 1-2 LP100 Microplasma Sensor Cell

The Quantus LP100 creates a plasma by coupling energy into the gas utilizing a

patented planar antenna in the Microplasma Sensor Cell. The antenna is protected

by a sapphire window so it is not exposed to the process chamber or gas sample.

This provides the LP100 its unique operating capabilies that allow the sensor to

operate in corrosive and aggressive environments. The planar antenna is built

using PCB techniques that provide tight tolerances and high performance. The

Microplasma Sensor Cell can be replaced in the field.

1.8.4 LP100 Electronic Control Module

The Electronic Control Module includes an optical spectrometer and control

electronics. It is powered by a 24 V (dc) power supply, has a cooling fan and six

status LEDs. Primary communication is through a USB port. Auxiliary I/O is

available through a 15-pin D-sub connector.

1 - 8

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.9 AUX I/O Connector

1.9.1 Auxiliary I/O Specifications

1.9.1.1 Mechanical

15-pin D-sub male connector used on Electronic Control Module. 15-pin D-sub

female mating connector required.

1.9.1.2 Electrical

1.9.1.2.1 Digital I/O

Signals I/O 0 to I/O 3 can be set or read by the Quantus. These four (input or

output) bi-directional auto-sensing level shifters are TTL-compatible I/O

connections rated for 0 to 5V (dc) with 10 k-ohm pull-up impedance. As digital

output connections, each can source a maximum of 0.5 mA. As digital input

connections, each can sink a maximum of 1.0 mA. The user is responsible for

limiting the input current to the 1.0 mA maximum.

1.9.1.2.2 Relay

A contact closure relay, single-pole double-throw (SPDT) is included in the

Quantus Electronic Control Module. Maximum current is 0.5 A, maximum voltage

is 50 V (ac). The relay is controlled by FabGuard software. The normal (inactive)

state is electrical continuity between pins 1 and 3, pin 2 open. The active state

switches to continuity between pins 2 and 3, pin 1 open.

1.9.1.2.3 Valve Driver

24 V Valve Driver, powered by the Quantus Electronic Control Module and

controlled by FabGuard software. Valve is open when circuit is active, which is

when pin 7 is grounded by the Quantus Electronic Control Module.

1.9.2 Auxiliary I/O Pin Designations

Table 1-2 AUX I/O Pin Designations

AUX I/O 15-pin D-sub Connector

Pin # Signal

1RelayNC

2RelayNO

3 Relay Common

4 I/O 2

5 I/O 1

6 I/O 0

7 Valve Control Return

1 - 9

IPN 074-510-P1B

Quantus LP100 Operating Manual

1.10 Quantus LP100 Specifications

Table 1-3 details the specifications for the Quantus LP100 gas analysis system. As

a result of the continuous product improvement and quality assurance programs in

place at INFICON, these specifications are subject to change without notice or

obligation.

NOTE: All specifications are measured after a 1 hour warm-up period.

8 Valve + 24 VDC

9 I/O 3

10 No Connection

11 No Connection

12 GND

13 GND

14 GND

15 GND

Table 1-2 AUX I/O Pin Designations (continued)

AUX I/O 15-pin D-sub Connector

Pin # Signal

Table 1-3 Quantus LP100 Specifications

Parameters LP100

Performance

Technology Optical Emission Spectroscopy using proprietary

and integrated ICP microplasma, spectrometer

and RF power supply

Spectrometer Performance 200 to 850 nm wavelengths (UV-Vis)

16-bit full-scale resolution, 2048 pixels

Integration Time Minimum of 1ms

Detection Limit To low PPM levels

(Application dependent)

Gas Sampling Interface

Process Environment 10.01 to 1 Torr

(Application dependent)

Vacuum Fitting KF25

Maximum Flange Temp 80°C

1 - 10

IPN 074-510-P1B

Quantus LP100 Operating Manual

Serviceability Sensor Cell is field replaceable

Facilities

Operating Temp Range 0-50°C (non-condensing, Sensor Cell 80°C)

Power Requirements 24 V (dc) @ 2.5 A (AC/DC converter provided)

Power Consumption < 25 Watts (typical, steady-state operation)

Carrier Gases None required

Mounting Options Direct Mount via KF25 Flange

Approximate Dimensions and Weight

Dimensions 3.4" H x 5.9" W x 9.5" L

(87 mm x 15 1mm x 241 mm)

Weight 5.9 lbs. (2.7 kg)

1Pressure range for argon. Pressure range may differ per application.

Table 1-3 Quantus LP100 Specifications (continued)

Parameters LP100

Table of contents

Other Inficon Test Equipment manuals

Inficon

Inficon MPG400 User manual

Inficon

Inficon E-Check Quick guide

Inficon

Inficon 122 20 User manual

Inficon

Inficon 122 20 Quick guide

Inficon

Inficon ULTRATEST UL3000 Fab PLUS User manual

Inficon

Inficon TC1000 User manual

Inficon

Inficon MCT150 User manual

Inficon

Inficon TGF10 User manual

Inficon

Inficon FTC3000 Quick guide

Inficon

Inficon TL3-5 User manual