HEALTH AND SAFETY

Installation and service of the equipment should be

performed by authorized and trained personnel.

Safety measures and local guidelines must be

followed. Use good practices wearing personal

protective equipment (PPE) during the installation

and service of the equipment.

Electricity – Aries Filterworks lab water equipment

should be powered by a grounded GFI electrical

connection. Do not open the cover unless the

system is unplugged. Before any installation or

service is performed on the equipment, make sure

the power is isolated. To unplug the system, do not

pull directly on the cord but grip the plug and remove

it from the outlet.

Ultraviolet Light – Aries Filterworks lab water

systems may include an ultraviolet light bulb in a

stainless steel housing. Make sure all power is

removed prior to accessing the side panel to perform

any UV maintenance. Make sure gloves are used

when handling the UV bulb. (Gloves must be worn

when handling the UV bulb. Which protects the

integrity of the bulb) Do not look directly at the UV bulb

while the system is operating.

Water Supply – Good piping practices should be

followed feeding water to the lab equipment. Isolation

valves, pressure gauges and bleed valves are

recommended on the main water supply. Pressure

should be regulated to meet the minimum and

maximum specifications stated for the equipment.

Sanitization – Make sure PPE is worn during any

sanitization process. The Phoenix system uses

chlorine dioxide gas as a disinfectant. Gas is

generated within the system, but the chlorine

dioxide gas will be discharged during sampling

and flushing sequences. Chlorine dioxide gas is a

respiratory irritant. Avoid breathing fumes and

ensure the area is sufficiently ventilated.

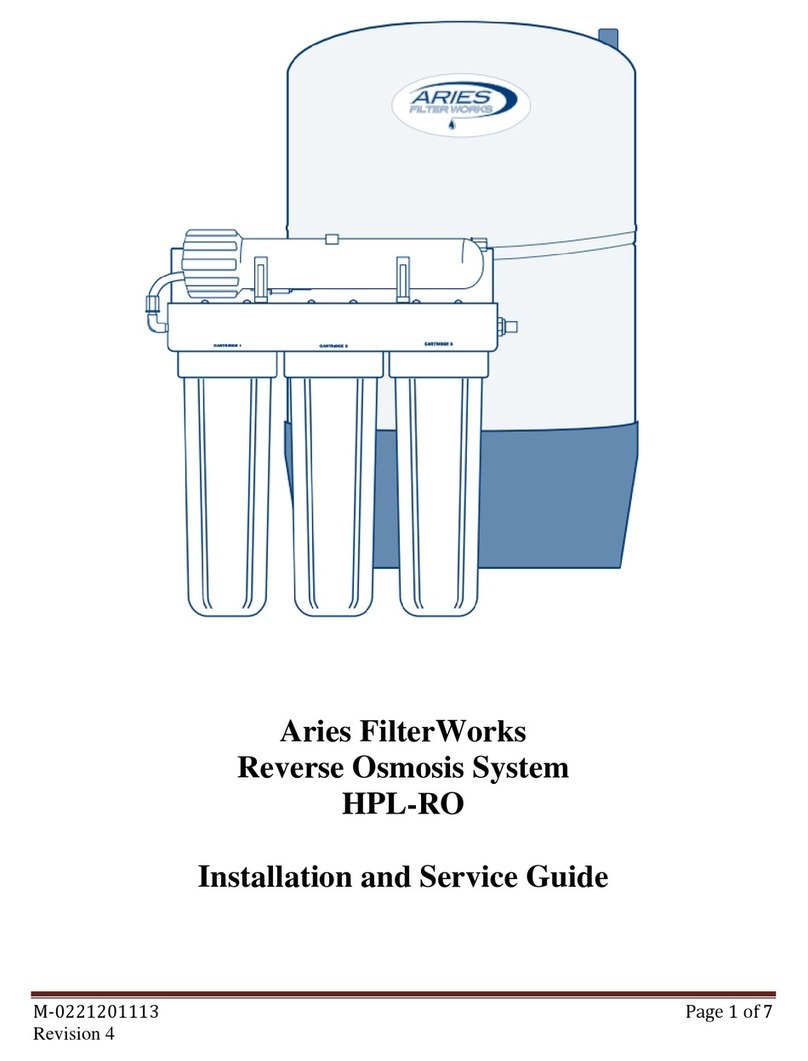

SYSTEM OVERVIEW

Phoenix Ultra High Purity Lab Water System delivers

Type 1, 18.2 MΩ quality water on demand. Water is

purified in a staged process consisting of high-purity

ion exchange resins to remove dissolved minerals and

internal recirculation to maintain purity. At discharge a

final 0.2µm filter removes particulates and bacteria to

attain CLSI / ASTM Type 1 water specifications.

Additional optional technologies are incorporated

depending on model. Multiple sensors continuously

monitor system and final water quality.

The Phoenix system is designed to recirculate

through multiple technologies to maintain purity. At

designated periods, the system will transition from

“Polishing” mode to “Stand By” mode and the

recirculation pump, solenoid, and UV (if installed) will

be automatically turned off via the PLC Controller. The

main screen provides resistivity, TOC (if installed) and

the life of the consumables. The status bars will

transition from green, to yellow and to red. The user

will still be able to operate the unit during all of these

conditions. The Phoenix comes with a built in Leak

Detector and when alarmed, it will automatically shut

down the system. Alarms and service events are

conveniently logged. The Phoenix comes with

volumetric dispensing and provides the user six

different batch sizes. The user can enter in a numeric

value, in mL units, for repeated dispensing. A button

is pressed and it will stop automatically once the limit

has been reached.

1 / PHOENIX ULTRA HIGH PURITY WATER SYSTEM