Contents ARMANNI

2.3 Responsibility...........................................................................................…… 2-3

Chapter 3 Installation 3-1

3.1 Storage.....................................................................................................…... 3-1

3.1.1 Characteristics of the storage area....................................................…. 3-1

3.1.2 Environmental characteristics of the storage area............................…. 3-2

3.2 Transport................................................................................................…… 3-2

3.2.1 Transport conditions........................................................................….. 3-2

3.2.2 Transport.........................................................................................…… 3-2

3.2.3 Lifting.............................................................................................…... 3-2

................................................................................................................…… 3-3

3.2.4 Preliminary operations....................................................................…. 3-3

................................................................................................................…… 3-4

3.3 Collocation..............................................................................................…... 3-4

3.3.1 Physical characteristics of collocation...............................................….. 3-4

.................................................................................................................…… 3-5

3.3.2 Environmental characteristics of the collocation area..........................…. 3-5

3.3.3 Connections.....................................................................................….. 3-5

.................................................................................................................…… 3-6

3.4 Test.........................................................................................................…… 3-7

Chapter 4 Use 4-1

4.1 Operator's qualification............................................................................….. 4-1

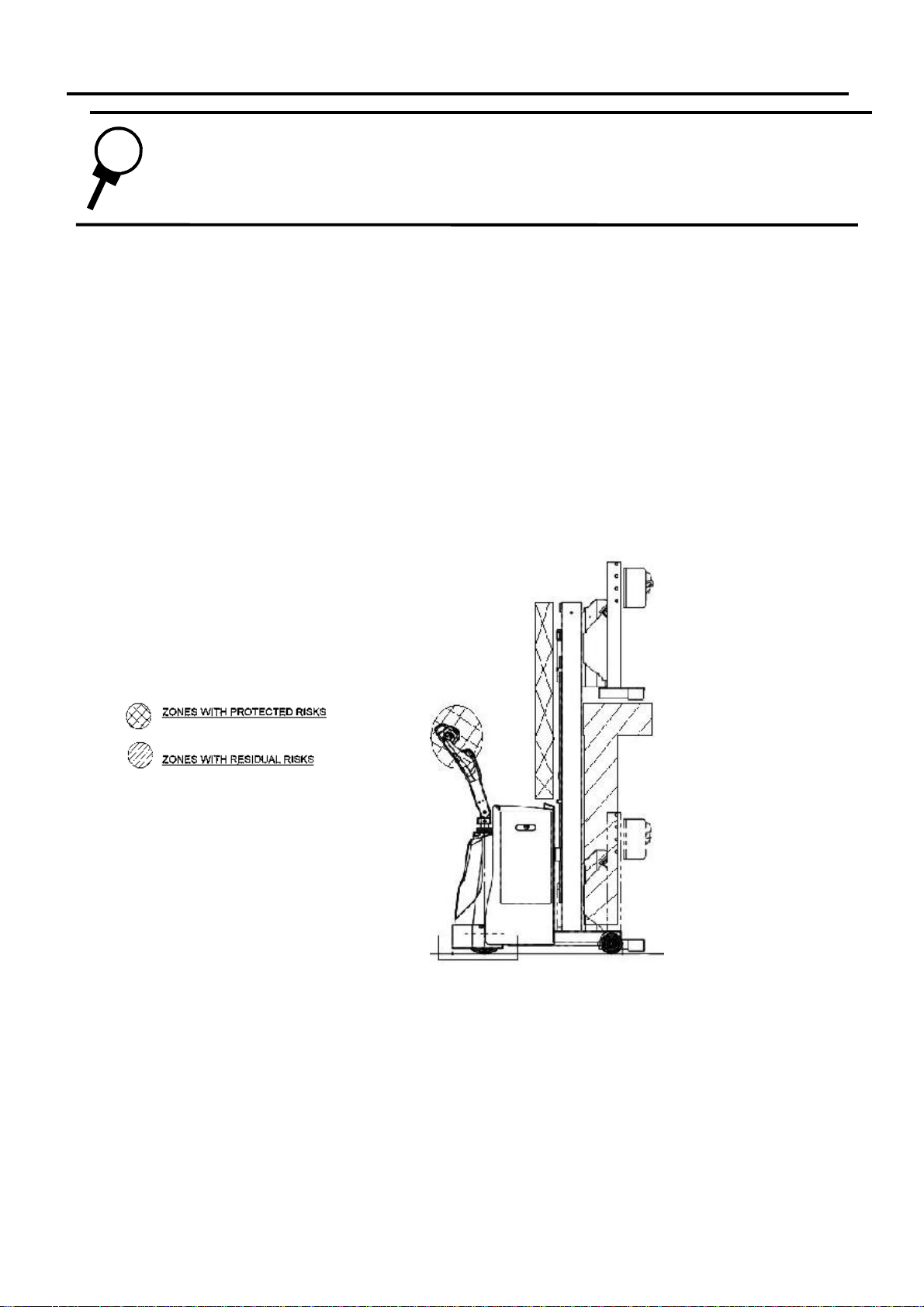

4.2 Danger zones........................................................................................…… 4-1

4.3 Drives and signals.................................................................................……. 4-2

4.3.1 Drives.......................................................................................…… 4-2

.................................................................................................................…… 4-3

4.4 Working....................................................................................................…… 4-3

4.4.1 Machine setting and ignition..................................................….. 4-3

4.4.2 Suggestions for a good piling-up.....................................................….. 4-3

.............................................................................................................…… 4-4

4.4.3 Working modalities...........................................................................…... 4-4

4.5 Working problems..................................................................................…… 4-5

4.5.1 The truck does not move..............................................................…... 4-5

.................................................................................................................…… 4-6

Chapter 5 Maintenance 5-1

5.1 Maintenance obligations in accordance with CE 2006/42 directive.........…. 5-1

5.2 Periodical maintenance checks and technical advice..............................…. 5-2

...........................................................................................................…… 5-3

5.3 Danger zones..........................................................................................…… 5-4

5.4 Routine (periodical and preventive) maintenance.....................................….. 5-4

5.4.1 Operator's qualification......................................................................…. 5-5

5.4.2 Cleaning......................................................................................…… 5-5

5.4.3 Periodical inspections...................................................................…... 5-6

5.4.4 Special maintenance.....................................................................….. 5-7