2

General Overview

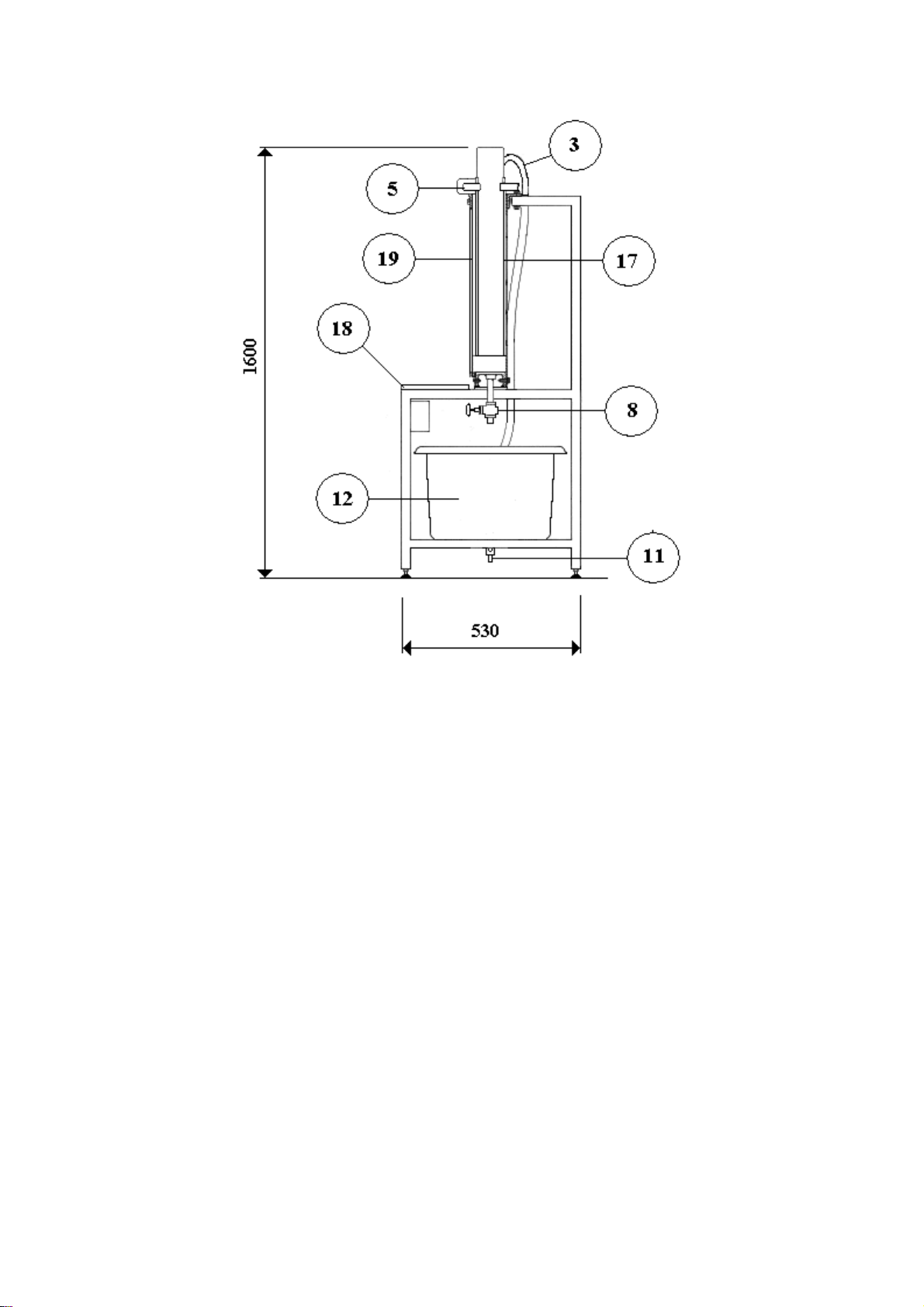

The class of problems involving flow of water through permeable media has a wide

range and is of considerable importance to engineers and scientists. The Armfield

Drainage and Seepage Tank, Model S1, facilitates a detailed study of the movement

of water through permeable media.

The engineer is probably the one who faces such problems most frequently and

whose success or failure will often depend on his knowledge and understanding of

phenomena related to the movement of the water in soils. This is one of the most

important aspects in the design of almost all hydraulic structures. Consider an earth

or rock fill dam, for instance. Water flows directly through the engineering structure

itself. Obviously, it is important to know how much water we can expect to lose from

the reservoir by seepage through the dam. We also need to know whether a certain

kind of soil can be used to construct the dam without running the risk that the

reservoir will run dry after filling. The safety and the very existence of the dam

depends on the flow pattern of the penetrating water and on the balance of the

hydraulic and static forces. Many earth dams have collapsed because of improper

design with respect to the movement of water through their bodies. In fact, the

conditions of seepage are vital, not only for earth dams, but for any dams having

permeable materials in the foundations. A dam can collapse or be badly damaged as

a result of seepage underneath its bottom, or because of hydrostatic forces exerted

by the penetrating waters. These forces cannot be determined without prior

determination of the flow pattern underneath the structure. Once known, they can be

altered using drains, cut-offs, sheet pile walls and other means to change the flow

pattern.

Similar problems arise in other engineering structures built from, or on, soil. As

examples, we can mention levees, road and railway embankments, canals,

navigation locks, foundations of buildings, bridges, harbour walls and similar

structures.

Another engineering field where good understanding of water movement in soil is

essential is water supply and drainage. In both we are concerned with extracting

water from saturated strata by using wells, horizontal galleries, tile lines, or trenches.

In this type of problem, we usually deal only with the flow pattern and quantity of the

water traversing the strata. The forces exerted by seepage remain of secondary

importance.

Mining is an area where both seepage and ground water flow is fundamentally

important. The design of an effective drainage system for a mine must be based on

profound knowledge of permeability, of the degree of water saturation of the various

geological layers, of seepage rates and of the effect of pumping or draining the water

on the balance of forces.

Ground water hydrology and hydrogeology are the main non-engineering fields

dealing with flow of water through permeable media and require the study of

problems such as salt water intrusion into fresh water basins, underground

movement of water towards inner channels, discharge of ground water into surface

run-offs, recharge of water from rivers to underground storage, artificial recharge of

ground water.

Generally speaking, the movement of water through soil under natural conditions is

very complex and cannot be reproduced in full in the laboratory. This complexity is

caused by the non-uniformity of natural soils over large areas, the stratified and the

tectonic structures of geological layers, and by the fact that water movement in