General Overview

The extraction (leaching) of a substance from a solid material with the aid of a liquid

is a common process in chemical engineering which can be applied to appropriate

biological, inorganic and organic substances. A familiar activity which illustrates this

process is the making of tea or coffee, where hot water is used to perform the

extraction from tea leaves or coffee beans. Other examples are the extraction of

sugar from sugar beet using hot water and the extraction of oils from seeds using

organic solvents such as hexane, acetone or ether.

For the solid/liquid extraction process to be appropriate, the substance to be

extracted (tea) must be soluble while the solid phase (tea leaves) must be insoluble

in the chosen solvent (hot water). The appropriate solvent is introduced to the solid

material and the two remain in contact while the soluble component dissolves into the

solvent. The solvent containing the dissolved substance (the miscella) is then drained

from the insoluble solid. This is the basis of all solid/liquid extraction processes.

Further processing may be required to recover the extracted substance from the

solvent.

Before performing solid/liquid extraction the solid material must be prepared by

crushing, grinding or cutting, as appropriate, to allow adequate contact between the

solvent and the soluble component. The amount of preparation will depend on the

amount and distribution of the soluble component within the solid and the nature of

the solid (how easily diffusion can occur).

Numerous different types of solid/liquid extractors may be employed to perform the

basic task of introducing the solvent to the material to be extracted. The extraction

process may involve batch operation (fixed-bed) with the addition of open loop or

closed loop circulation of the solvent. Alternatively extraction may be a continuous

operation (moving-bed) with single or multi-stage processing involving co-current flow

or counter current flow of the solvent and the soluble material to be extracted. In

large scale industrial solid/liquid extraction systems economic factors frequently lead

to the use of the more sophisticated multi-stage counter current flow systems due to

their high extraction efficiency.

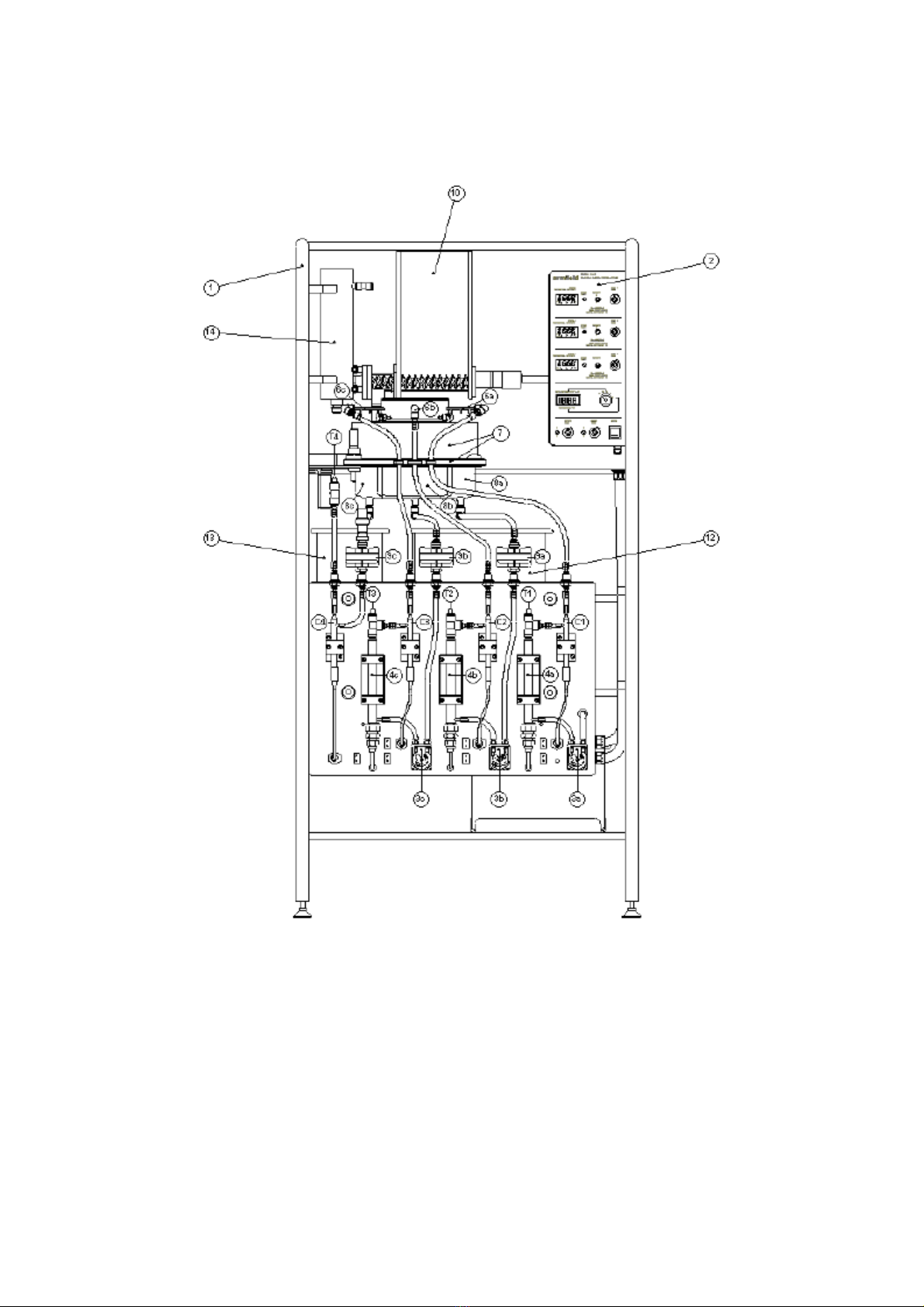

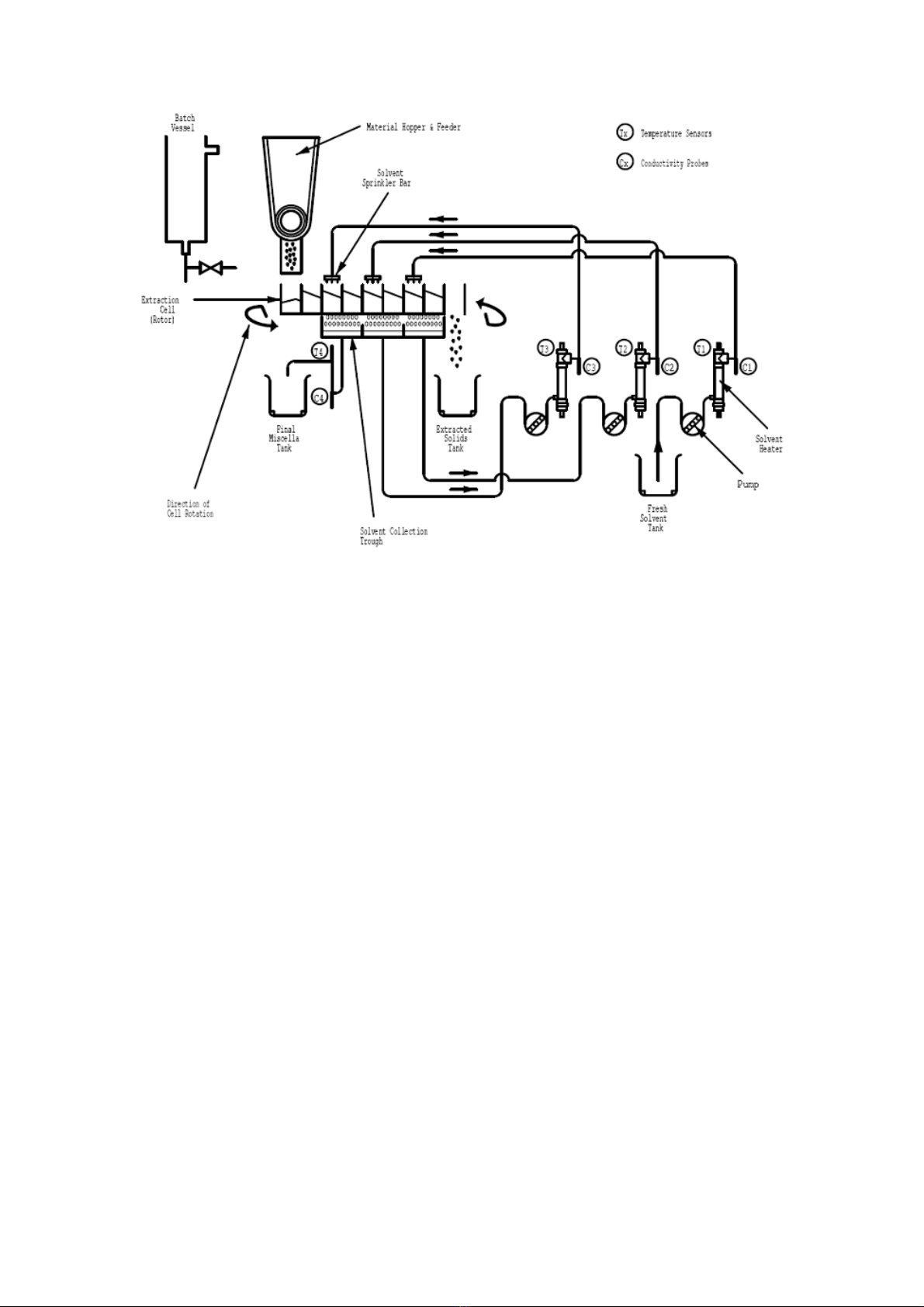

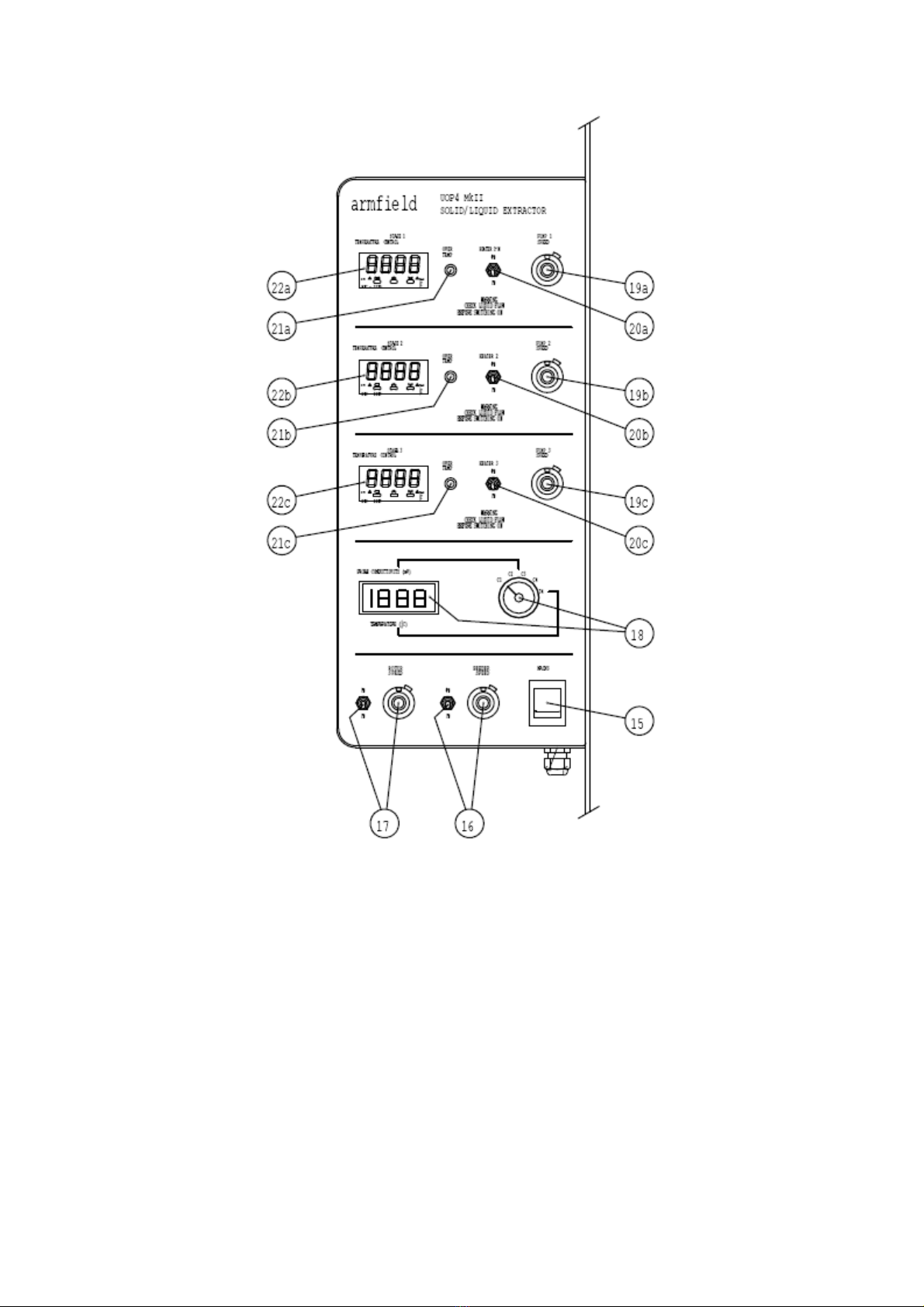

The Armfield UOP4 MkII is designed to demonstrate a simplified version of the

moving-bed leaching process used by many industrial solid/liquid extraction systems.

The process used is a continuous multi-stage process, which gives counter current

flow of the solvent and the solid phase. A batch extraction vessel is also incorporated

to allow demonstration of fixed-bed leaching with either open or closed loop

circulation of the solvent. The recommended process for the UOP4 MkII is the

extraction of Potassium Bicarbonate from a solid carrier of porous polymer pellets

using water as the solvent.

2