7

KXMANUAL

www.eaeelectric.com

www.eaeelectric.com www.eaeelectric.com

www.eaeelectric.com

4

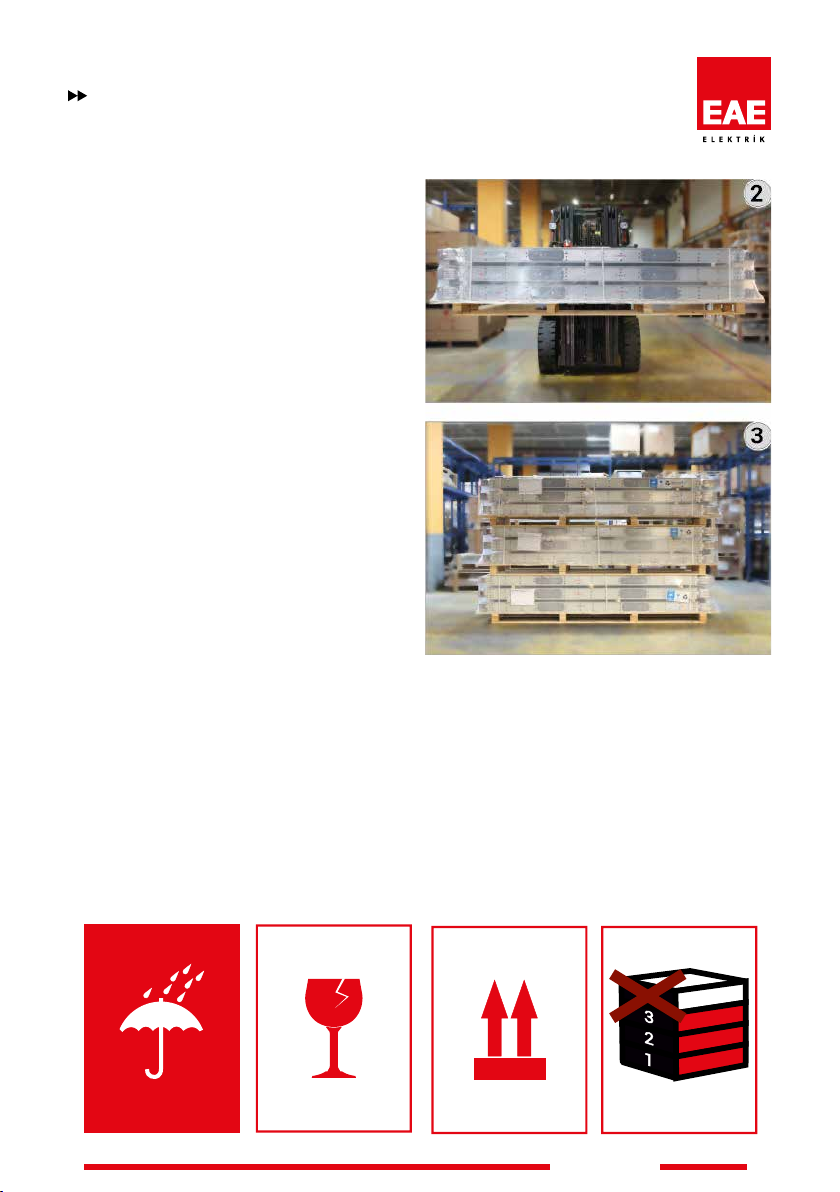

min. 150cm - mak. 200cm

+

Installation

Points to be taken into consideration before installation

IMPORTANT!

1- Please read the instruction manual before

commencing the Busbar installation. Incorrect

or rudimentary installation may caused

damage to the equipment or systems.

2- Installation of the Busbar systems should

only commence after understanding and

interpreting the Busbar application drawings.

Locate the positions of individual components

such as expansion units, feeder units, feeder

unit ends and transformer panel connections,

etc. These should always be executed

according to the project drawings

3-All busbar products are 100% isolation

resistance tested before shipment to our

valued customers world wide. Unloading and

storage must conform to our policies, pertaing

to environmental conditions and construction

sites. All Busbar products must be isolation

resistance tested before installation

commences, these include individual Busbar

products, single conductors (between phases:

phases and neutral and neutral and earth)

Isolation Resistance Test (min. 1000V AC) is

recommended. The measured value must not

be less than 1(one) Megaohm. All products

above 1(one) Megaohm may be installed.

Results may differ from country to country due

to environmental conditions. Commencement

of Installation without a isolation resistance

test may lead to product failure, consequently

the manufacturer (EAE Elektrik A.Ş) will not

accept liability.

4- Seismic support systems should be used

in high risk earthquake areas. Please contact

our knowledgeable sales staff for details of

seismic support products and project planning.

The recommended distance between supports

are 1.5m and the maximum is 2m. Ensure that

support positions do not obstruct joint covers

and tap off points.

5- DDT modules that are used on a concrete

floor should be positioned at intervals of 20cm.

6- If the Busbar lines are used in the transition

of the building dilatations, appropriate

dilatation modules should be chosen. Please

contact our knowledgeable staff for support.

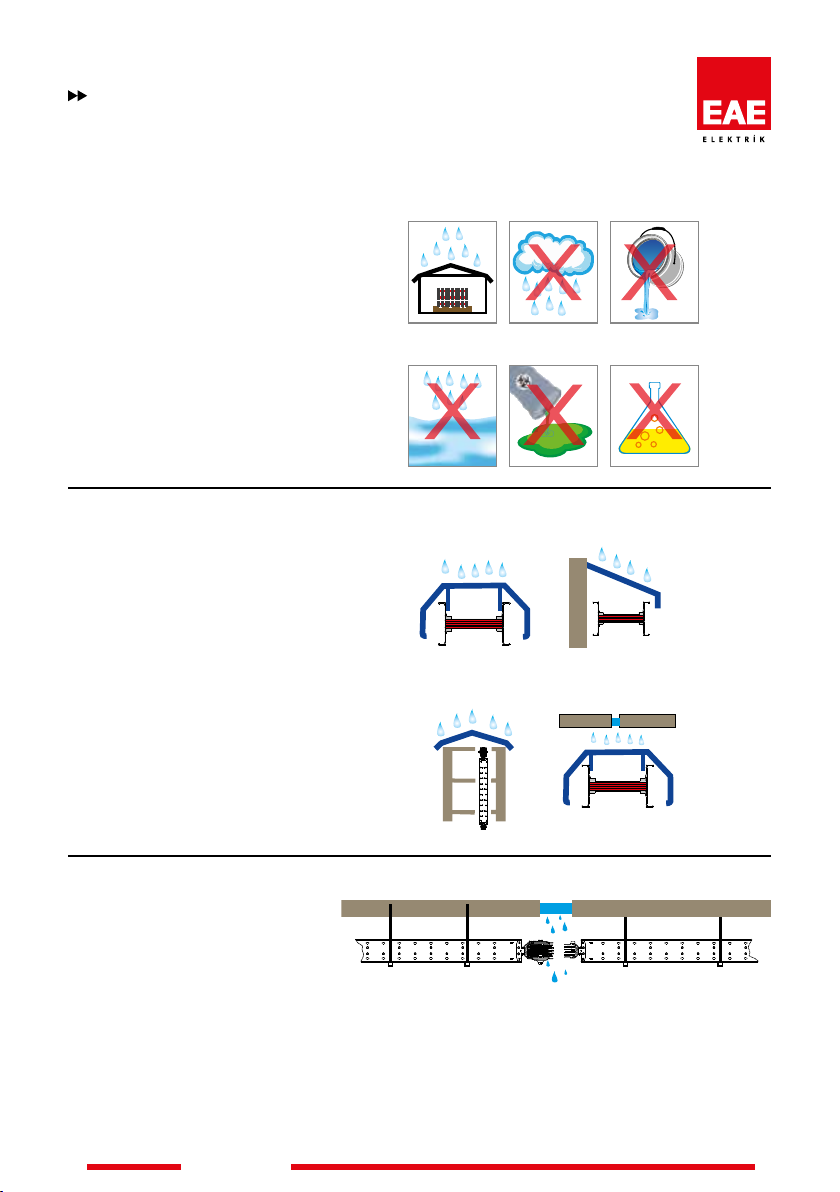

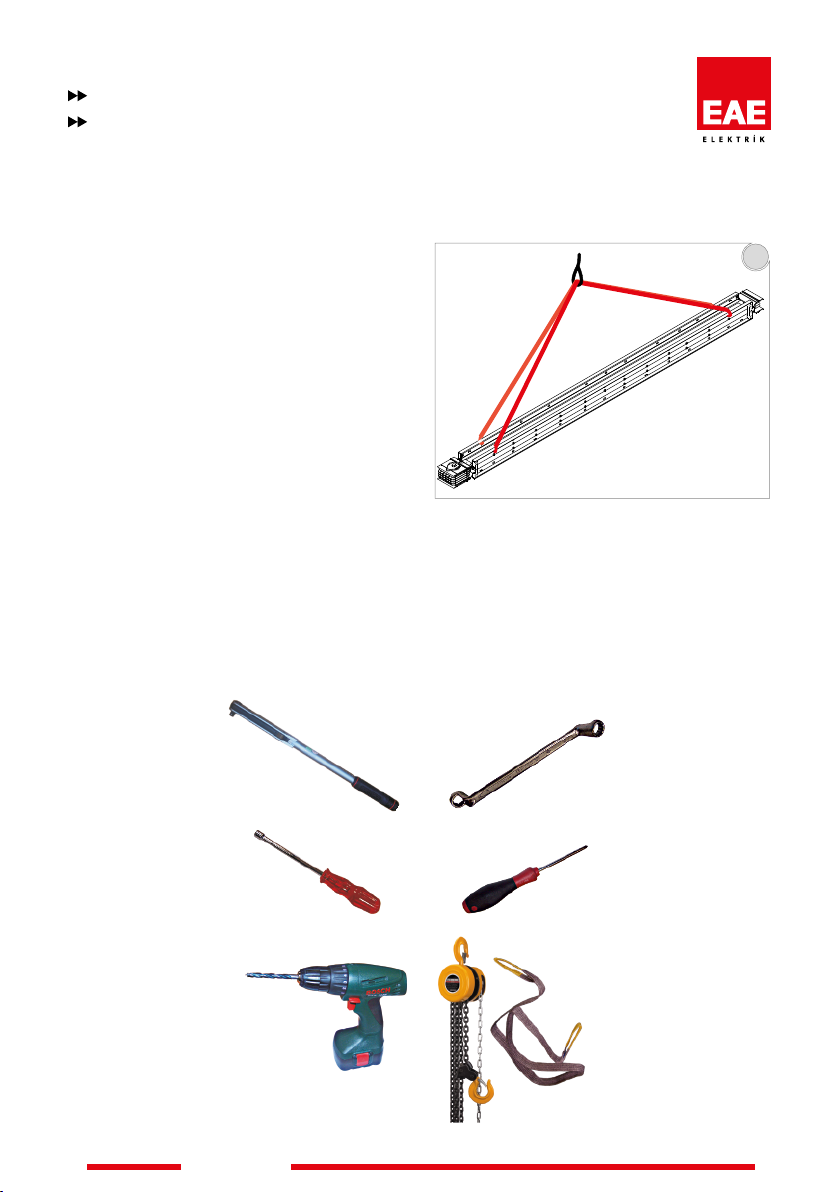

7- Busbar systems should be installed with care

when using a forklift, crane or pallet trolleys

to avoid any damage. When transporting the

products ensure that the weight is evenly

distributed. Generally vertical installation is

provided in vertical lines.

8- Please read the additional installation

instructions.

9- When installing horizontal and vertical

systems, ensure that it is aligned correctly to

prevent distortion and collapsing.

Protect the Busbar against water and moisture

from unnished roofs and walls during

installation.

Please cover

top of the shaft.