installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

7

Place pumping unit on the foundation and insert metal wedges

on either side of the foundation bolts under base plate. Leave

approximately 0.75" (19mm) space if grouting.

Carefully level the unit by adjusting the wedges until base is

supported in a level position

With the proper gauge, check suction and discharge flanges of

the pump for proper positioning.

When the baseplate is completely level, the foundation bolts

should be tightened evenly and firmly.

1.2.3 grouting

Armstrong’s fabricated steel base plates, as supplied with

4200H Design Envelope pumps, are manufactured to ansi/hi

1.3.5 rigidity standards for free-standing base plates. As such,

no grouting in place is necessary for the base plate to hold shaft

alignment of any Armstrong base mounted pumping unit. End-

suction horizontal base mounted Design Envelope pumping units

are supplied with rigid couplings which need no re-alignment at

installation or following seal service. Thus grouting is not neces-

sary; though the following instructions are for installers who still

wish to also secure the base in place with grout:

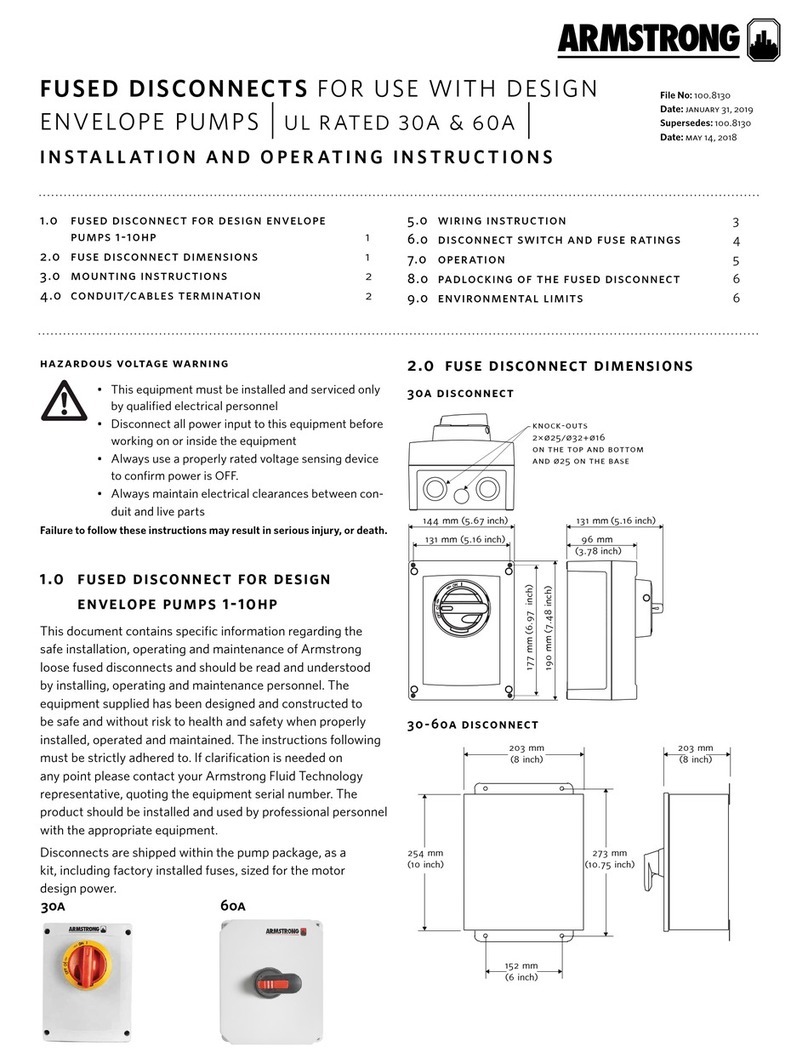

• Construct a dam around the foundation with grout forms, as

shown in the illustration.

• Use a good mixture of non-shrinking grout. The grout

should be the consistency of heavy cream.

• Spaces are provided in the base plate to permit pouring of

the cement and stirring. Fill under the base completely, stir-

ring to assure proper distribution of the grout. Check to see

that the grout flows under the base plate evenly.

• When the grout has hardened thoroughly, usually after

48 hours, final tighten the anchor bolts and remove the

grout forms.

1.2.4 pump piping – general

Never connect a pump to piping, unless extra care is taken to

measure and align the piping flanges well. Always start piping

from pump.

Use as few bends as possible and preferably long radius elbows.

Do not use flexible connectors on the suction or discharge of

a vertical in-line pump, unless the pump is rigidly mounted to

a foundation.

Ensure piping exerts no strain on pump as this could distort

the casing causing breakage or early failure due to pump

misalignment.

All connecting pipe flanges must be square to the pipework and

parallel to the pump flanges.

Suction and discharge pipes may be increased or decreased at

pump nozzle to suit pump capacity and particular conditions of

installation. Use eccentric reducers on suction connection with

flat side uppermost.

Layout the suction line with a continual rise towards the pump

without high points, thus eliminating possibility of air pockets

that may prevent the pump from operating eectively.

A strainer of three or four times the area of the suction pipe,

installed in the suction line, will prevent the entrance of foreign

materials into the pump. V" (3mm) diameter perforations in

the strainer is typical.

In open systems, test suction line for air leaks before starting;

this becomes essential with long suction line or static lift.

Install, at the pump suction, a straight pipe of a length equiva-

lent to four or six times its diameter; this becomes essential

when handling liquids above 120°f (49°c). Armstrong suction

guides may be used in place of the straight pipe run and in-line

strainer.

Install an isolation valve in both suction and discharge lines on

flooded suction application; these valves are used primarily to

isolate the pump for inspection or repair.

Install a non-slam non-return check valve in discharge line

between pump and isolation valve to protect pump from

excessive back pressure and to prevent water running back

through the pump in case of driver failure on open systems.

Armstrong Flo-Trex valves may be used in place of isolation

valves and non-return check valves. Flo-Trex valves use plug

& disk design which may also be used for throttling excessive

system flow for constant speed pumps and, if necessary, for

variable speed pumps. Do not throttle variable speed pumps

unless absolutely necessary.

note:

Design Envelope 4200H units are accurately aligned at the factory

prior to being shipped and do not need re-aligning when installed.

Alignment on a Design Envelope 4200H unit may be verified by

assuring an equal and parallel gap between coupling halves on

both sides of the coupling.

Install foundation bolts

Install grout forms

Fill in base with grouting