installation &

operating instructions

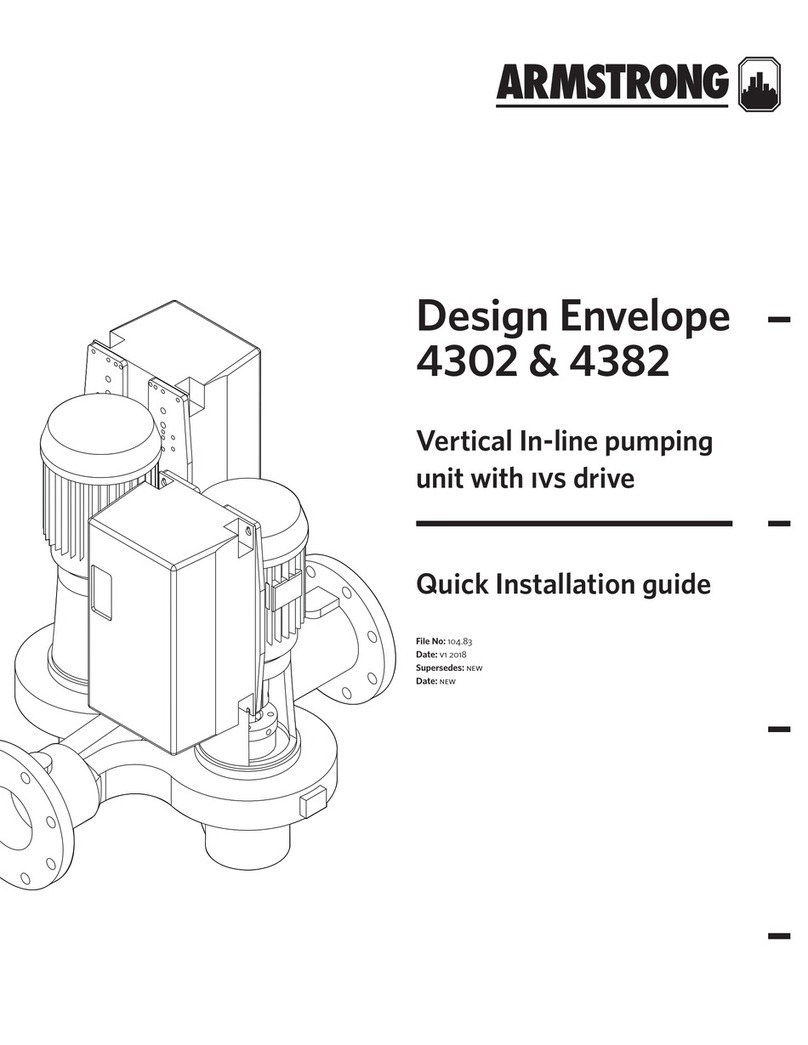

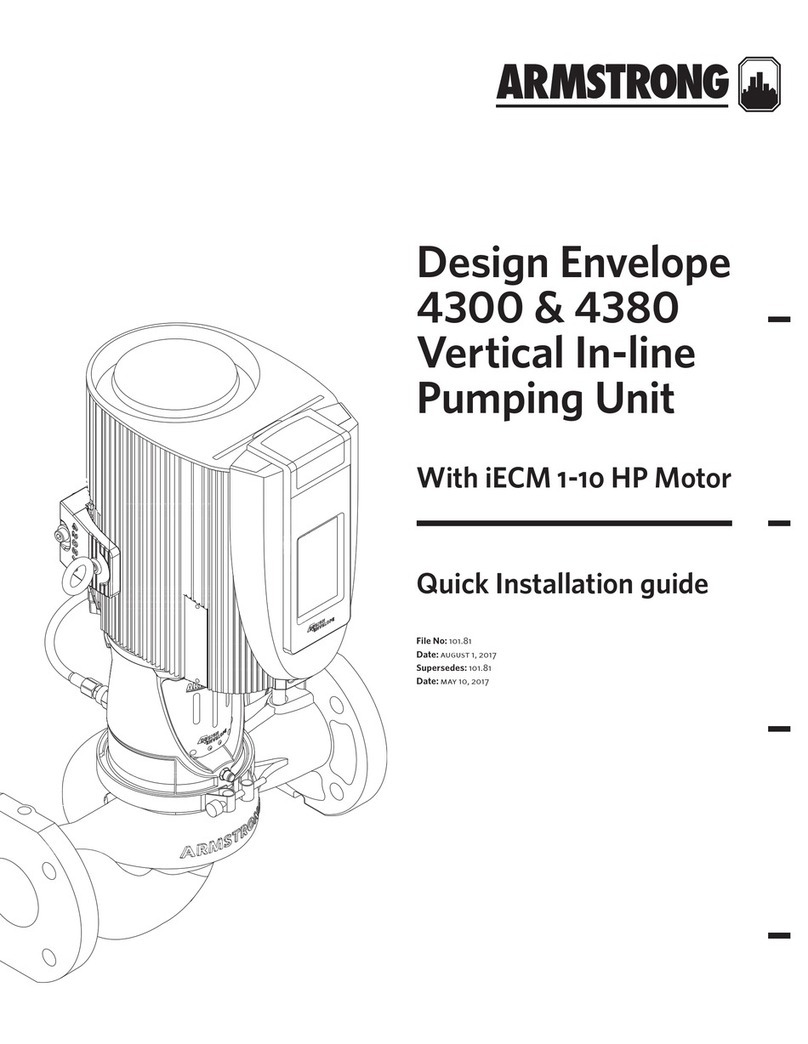

Design Envelope 4300 & 4380

Vertical In-line Pumping Unit

6

For Design Envelope 4300 units, remove the coupling guard and

insert lifting straps through the pump/motor pedestal on either

side of the coupling. For Design Envelope 4380 units, remove

the motor eye-bolt and install a swivel hoist ring tied to a lifting

strap. Place secondary lifting straps around the motor feet (and/

or spacers). As the lifting device is engaged (Using a spacer bar

if necessary) and the straps tighten ensure no part of the strap-

ping is touching any part of the control or motor fan cover. Lift the

pumping unit carefully from the pallet in this manner and allow the

unit to stand upright on a flat surface and re-position the straps, if

necessary, to ensure safe and damage-free transportation into the

pipe installation.

4300

4380

Remove coupling guard and

place lifting straps on each

side of coupling, use spacer

bar if necessary to protect the

integrated controls and motor

fan cover.

Remove the motor eye-bolt

and install a swivel hoist

ring tied to a lifting strap.

Place secondary lifting straps

securely around motor feet

(and/or spacers).

important:

Do not run the pump for any length of time under very

low flow conditions or with the discharge valve closed.

To do so could cause the water in the casing to reach

super heated steam conditions and will cause premature failure

and could cause serious and dramatic damage to the pump and

surrounding area.

2.0 installation

2.1 location

In open systems, locate the unit as close as practical to the liquid

being pumped, with a short, direct suction pipe. Ensure adequate

space is left above and around the unit for operation, maintenance,

service and inspection of parts.

In closed systems, where possible, the pumps should be installed

immediately downstream of the expansion tank /make-up connec-

tion. This is the point of zero pressure change and is necessary for

eective pump operation. Do not install more than one expansion

tank connection into any closed hydronic system.

Electric motor driven pumps should not be located in damp or

dusty location without special protection.

Airflow into the motor and/or motor fan should not be obstructed.

It is good practice to leave sucient space around equipment for

maintenance and service needs. If the ivs102 controls are sup-

plied with integral disconnect switches, 36ins / 1meter clearance

may be required in front of the controls to meet local electrical

codes.

2.2 installation

When installing vertical in-line pumps, an important consideration

to accrue full added-value from the pump design is to ensure that

the pump is pipe-mounted and free to ‘float’ with any movement,

expansion and contraction of the piping. Should any vertical in-line

pump use supports to the structure it is imperative that no pipe

strain is imposed on the pump flanges. Tell-tale pieces of equip-

ment such as springs or ‘wae’ style neoprene isolation pads

that distort with pressure to indicate added piping weight, should

be used under pump supports should the pump not be truly pipe

mounted.

Design Envelope 4300 and Design Envelope 4380 cannot be

mounted with shafts in the horizontal position.

Various installation arrangements are detailed on Pages 9–12

All Design Envelope 4300 pumps contain a tapped hole in the mo-

tor bracket above the discharge flange to drain condensate buildup

of seal leakage. (Fig. 2.14)

2.2.1

Vertical In-Line pumps may be installed directly in the system

piping with no additional support. Pipe hangers are simply sized

for the additional weight of the pumping unit. Many pumps are

installed in this manner and can be mounted at sucient height to

take zero floor space. (Fig. 2.1)

2.2.2

Piping in many mechanical rooms is hung close to the ceiling

and larger pumps are mounted near ground level for ease of

maintenance. Fig 2.2 illustrates such an arrangement with the

piping supported at the ceiling and the vil unit installed with an

Armstrong Suction Guide and Flo-Trex valve. Many very large vil

pumps are installed in this manner.

2.2.3

Should additional space saving be required the discharge spool

piece may be replaced by a long-radius elbow.