installation &

operating instructions

Design Envelope 4300 & 4380 Vertical

In-line pumping unit with ivs drive

8

Electric motor driven pumps should not be located in damp

or dusty location without special protection.

Airflow into the motor and/or motor fan should not be ob-

structed.

It is good practice to leave sucient space around equipment

for maintenance and service needs. If the ivs controls are

supplied with integral disconnect switches, 36"/1meter

clearance may be required in front of the controls to meet

local electrical codes.

1.2.2 installation

When installing vertical in-line pumps, an important

consideration to accrue full added-value from the pump

design is to ensure that the pump is pipe-mounted and free

to ‘float’ with any movement, expansion and contraction of

the piping. Should any vertical in-line pump use supports to

the structure it is imperative that no pipe strain is imposed

on the pump flanges. Tell-tale pieces of equipment such as

springs or ‘wae’ style neoprene isolation pads that distort

with pressure to indicate added piping weight, should be

used under pump supports should the pump not be truly

pipe mounted.

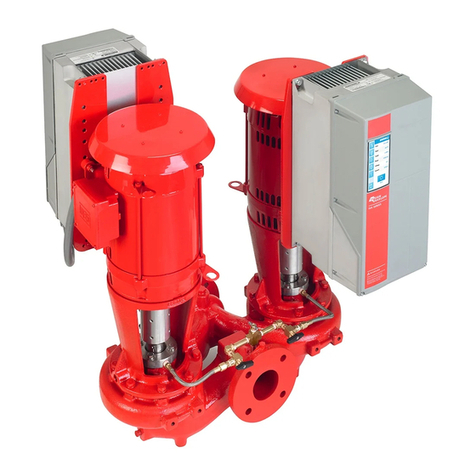

Design Envelope 4300 and Design Envelope 4380 cannot

be mounted with shafts in the horizontal position.

Various installation arrangements are detailed on pages 8–10

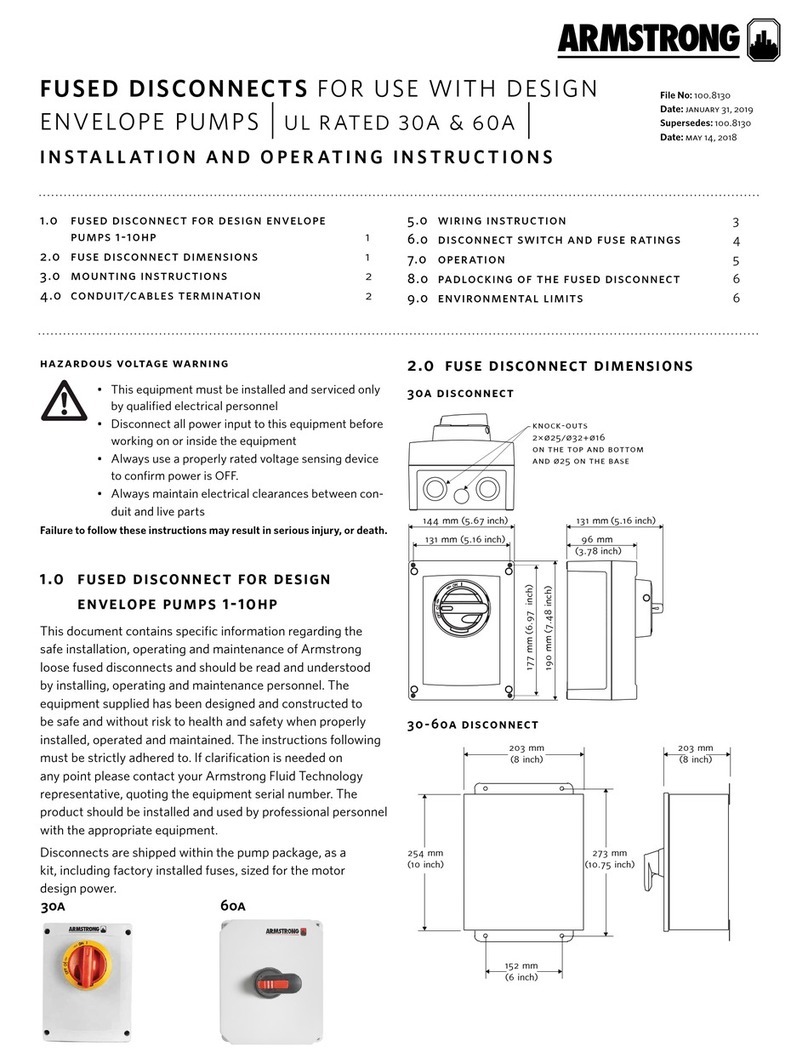

a Vertical In-Line pumps may be installed directly in the

system piping with no additional support. Pipe hangers

are simply sized for the additional weight of the pumping

unit. Many pumps are installed in this manner and can

be mounted at sucient height to take zero floor space.

(fig. 1.1)

b Piping in many mechanical rooms is hung close to the

ceiling and larger pumps are mounted near ground level

for ease of maintenance. fig. 1.2 illustrates such an

arrangement with the piping supported at the ceiling

and the vil unit installed with an Armstrong Suction

Guide and Flo-Trex valve. Many very large vil pumps are

installed in this manner.

c Should additional space saving be required the discharge

spool piece may be replaced by a long-radius elbow.

d fig 1.4 illustrates a similar arrangement to fig. 1.2 with

additional floor mounted pipe-stools isolated from the

structure by ‘wae’ style neoprene isolation pads under

the Armstrong Suction Guide and Flo-Trex valve.

e Floor mounted saddle supports (fig. 1.5) are typical for

condenser water pumps where cooling tower base is at

the mechanical room elevation.

fWhere required, additional floor support may be used as

shown in fig. 1.6. Note that the pump should not be rig-

idly attached to the column. Leave a small gap between

pump and column or install a wae isolation pad under

the pump. It is critical that piping be installed in such a

manner that the pump does not become a pipe support.

g fig. 1.7 illustrates stanchion plates at the pump inlet and

outlet ports that may be supplied for installation conve-

nience. Isolation pads must be used under the legs and

monitored as pipe hangers are adjusted to ensure the

pump flanges are not supporting the piping. Bolting to

the floor or housekeeping pad is not recommended. If the

stanchions are bolted down the bolts must be isolated

from the stanchion or an inertia base and flexible pipe

connectors used.

h fig. 1.8 illustrates installations with stanchion plates

for seismically active regions. Seismically rated isolation

pads or snubbers with bolts isolated from the stanchion

plates are installed to restrain the pump during a seismic

event. Pipe hangers carry the weight of the equipment

as seismic components are designed only to restrain the

equipment during a seismic event.

iMany Vertical In-Line pumps are piped successfully into

grooved piping systems. In-line pumps are supported

well by grooved piping however flange adapter locking

devices or a welded flange at the pump should be used to

prevent the possibility of pipe mounted pumps rotating in

the piping. Armstrong oers grooved suction guides with

cast-in outlet flanges and Flo-Trex valves with Armgrip™

fittings to prevent this possibility. (fig. 1.9)

jDo not support the unit by the motor eye bolts (fig.

1.10) or by any other part of the motor.

k Connecting the pump to a permanent rigid base (fig.

1.11) is not recommended unless isolated from the piping

by flexible connectors and the base isolated from the

building structure on an inertia base. (fig. 1.11 is gener-

ally acceptable when using plastic piping).

l The motor and integrated control assembly can be

rotated in 90° increments to meet installation spacing

requirements. Where applicable, remove the coupling

guard to access the motor bolts.Remove the motor bolts

to rotate the motor and integrated control assembly by

hand.Larger motors may need strapping and slight lifting

to break the contact with the pedestal.Care should be

taken that the controls are not damaged during lifting

and that the flushline, accessories and the coupling guard

removal/seal service window are not compromised fol-

lowing the turn (fig. 1.12).vil pumping units without

integrated controls can also be rotated in a similar man-

ner to facilitate access to the the motor terminal box.

mFor d1 and d2chassis ivs units (150 hp–350 hp), ensure

adequate space is available for the access door to swing

open. (fig. 1.13)