Intelligent Variable Speed Booster Systems: Basic Operating Function

Every Armstrong Intelligent Variable Speed (IVS)

Packaged System – regardless of size or horse power

rating – incorporates the twelve (12) basic operating

functions as follows:

1. For Continous Run and Intermittent Systems - Sequential

starting and stopping of the pumps is achieved by a

combination of pump speed, power and set point

pressure. A set point pressure control will bring on a lag

pump if the lead pump(s) are operating at full speed and

not maintaining set point pressure. When the lead pump

reaches 100% speed or maximum motor nameplate

power and the system pressure is not being satisfied, the

second pump (lag pump) is automatically started. When

a lag pump is started up, a timeclock in the pump

controller keeps it operating for a minimum of a 1 minute

period to prevent the pump from cycling on and off. On a

three, four or five pump system, the third, fourth and fifth

pumps are brought on in the same way when the

combined pumps reach 100% speed or maximum motor

nameplate power and the system pressure is not being

satisfied. A similar sequence of events takes place in

reverse on decreasing demand.

2. Pump RPM is controlled by a Variable Frequency

Drive (VFD) connected directy to each individual

pump motor. An analog signal from the discharge

pressure transmitter is compared to a desired set

point entered in to the operator panel. The pump

logic controller then instructs the VFD to either speed

up or slow down in order to meet or maintain the

system set point pressure.

3. A low suction pressure or level shutdown alarm is

included with every system to protect the pumps from

a loss of suction pressure or water supply. If the water

supply pressure, as measured by the suction pressure

transmitter falls to 5 psi or the tank level switch

(supplied by other) sends a signal to the panel, the

pump controller will prevent the pumps from running.

This condition is indicated by a "low suction pressure"

or "low suction level" alarm description on the control

panel alarm page.

4. Variable speed plumbing booster systems come with

the following standard alarm functions in addition to the

Low Suction Pressure/Level Protection;

-High Suction Pressure Shutdown

-Low Suction Pressure Shutdown

-High System Pressure Shutdown

-Low System Pressure Shutdown

5. Should a motor or drive overload and fail to operate,

the next pump in sequence starts up automatically.

6. Lead Pump status is alternated after every 24 hrs of

operation, as a default. The first pump placed in the

auto position is considered the lead pump. HOA

switches are located in the individual pump control

screens. Alternation includes all duty and optional

standby pumps.

7. No-flow shut down is achieved through drive

parameter control and pressure monitoring. Once a

no-demand condition is achieved for a period of 5

minute, the controller will increase the pump speed

and charge the drawdown tank or system an

additional 5 psi before shutting down.

8. A 15 second delay is incorporated in every system

restart. Once started, the pumps ramp up to meet the

required set point pressure.

9. The Soft Fill Mode is enabled when the booster

system is first powered and after any power disruption.

Once started, the pumps ramp up slowly to meet the

Soft Fill set point pressure or after a 5 minute

operational period and return to normal operation.

10. The Pressure Setback Mode is enabled as standard.

The system pressure set point is reduced linearly, as

a percentage, as flow decreases.

11. When the Emergency Power Mode is enabled and upon

receiving an Emergency Power digital signal, power and

control will be restricted to the lead pump only, the Low

System Pressure Shutdown will be disabled and the

Emergency Power Low System Pressure alarm will be

enabled. The one pump will operate for the duration of

the Emergency Power Mode and the system will switch

to Normal Mode when a signal is not present and the

minimum run timer has expired.

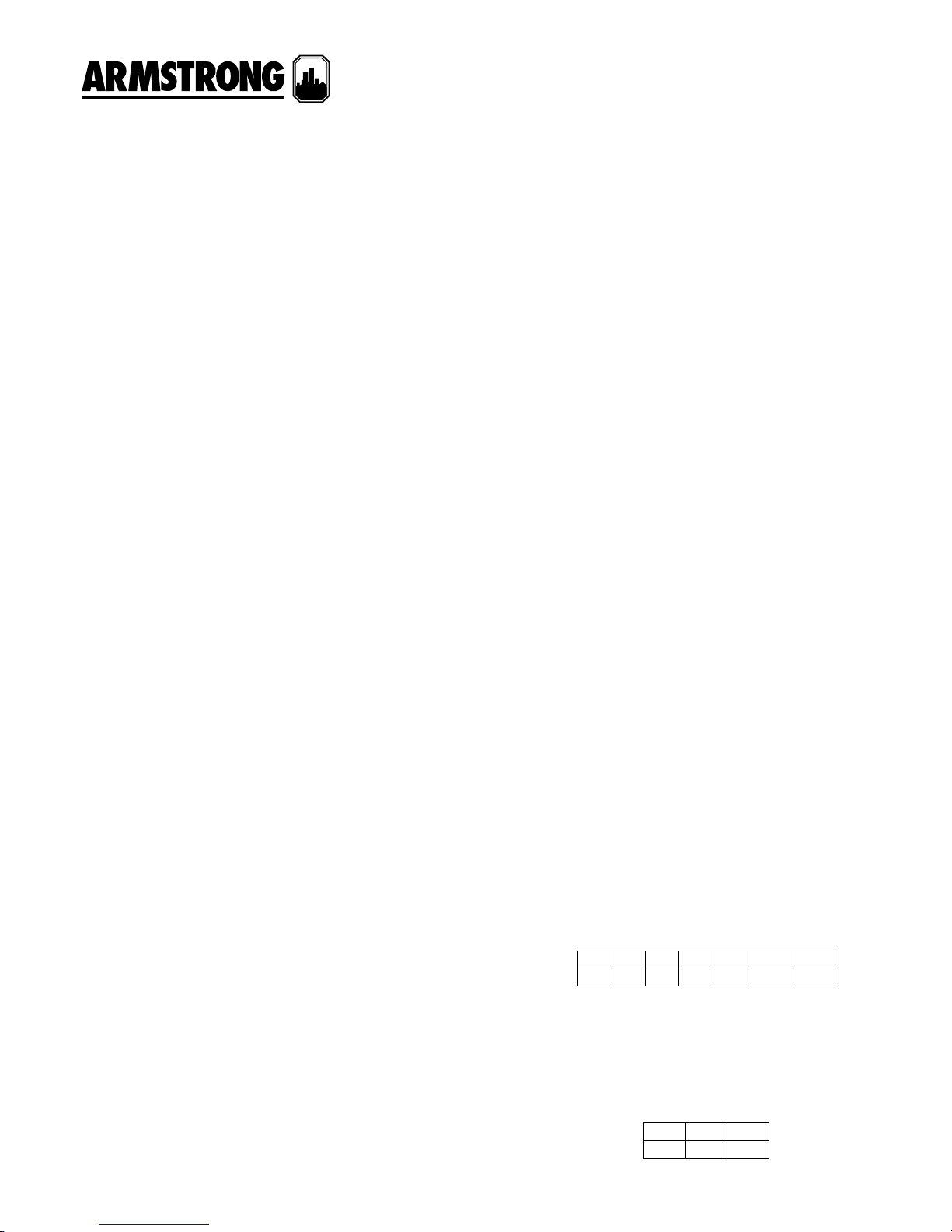

12. Variable Speed Controllers are supplied with up to 7

Normally Open (NO) dry contacts for remote

monitoring. The contacts are located on the upper left

hand portion of the pump controller and indicate the

following conditions:

1, 2 – Discharge Pressure Sensor

3, 4 – Suction Pressure Sensor

5, 6 – Remote Start

7, 8 – Level Switch 1 (Signal by Other)

9, 10 – Emergency Power (Signal by Other)

11, 12 – System Alarm

13, 14 – Pump Running

1+ 3+ 5+ 7+ 9+ 11+ 13+

2- 4- 6- 8- 10- 12- 14-

Communication Option

(Serial connection except for BACnet (IP/ENET))

15, 16 – BAS Communication

17, 18 – BAS/VFD Ground

19, 20 – VFD Communication

15+ 17+ 19+

16- 18- 20-

Page 5 of 34