8

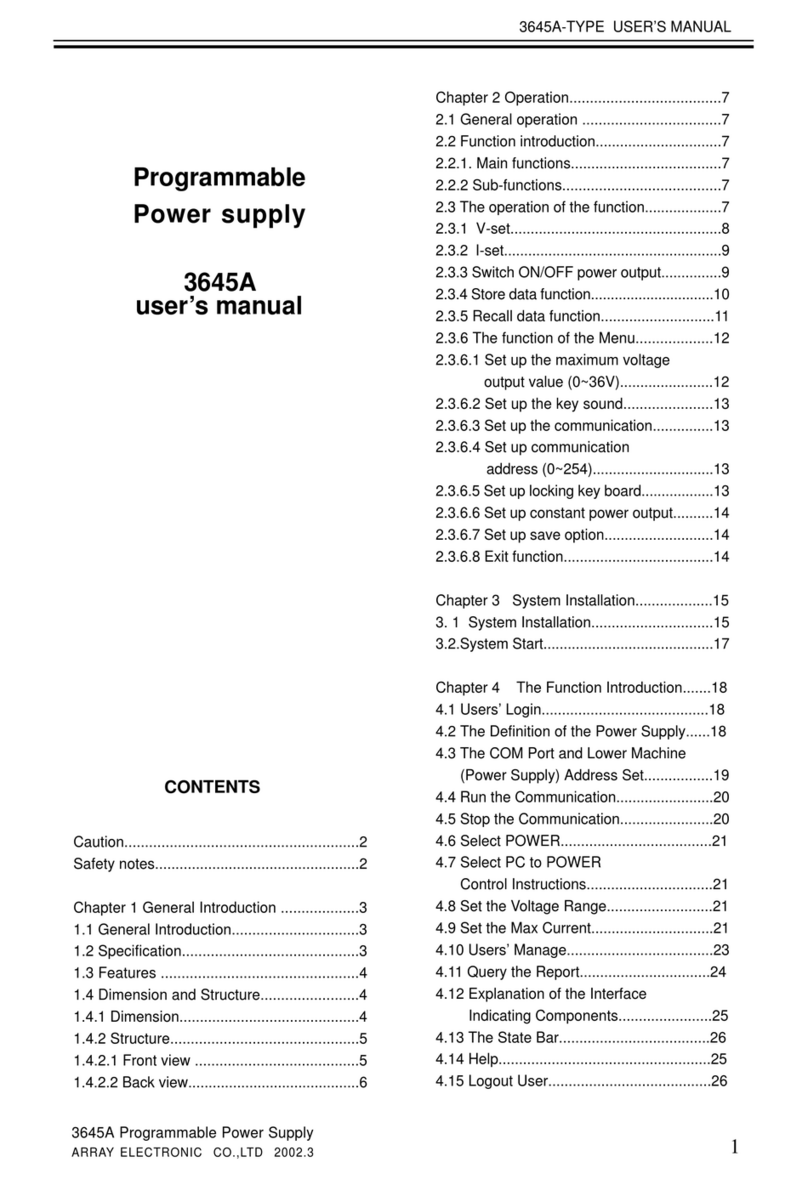

Menu Setting ………………………………………………………………………24

Main Menu Description…………………………………………………………….24

Storing and Recalling………………………………………………………………24

Error Messages Display…………………………………………………………….25

Local/ Remote Operation Switch…………………………………………………..25

Protection Function…………………………………………………………………26

Abnormal Latched State Clearance…………………………………………………26

Over-Voltage…………………………………………………………………………26

Over-Temperature…………………………………………………………………….26

The Power Supply Calibration……………………………………………………….27

Calibration Instrument………………………………………………………………..27

Cautions……………………………………………………………………………..27

Calibration Procedures………………………………………………………………27

Chapter 4 Remote Interface Reference ………………………………………….31

Remote Interface Reference………………………………………………………….31

SCPI Command Summary…………………………………………………………31

An Introduction to the SCPI Language…………………………………………….32

Command Format Used in This Manual……………………………………………33

Command Separators………………………………………………………………..34

Using the MIN and MAX Parameters……………………………………………….34

Querying Parameter Settings…………………………………………………………34

SCPI Command Terminators……………………………………………………….35

SCPI Parameter Types………………………………………………………………35

Numeric Parameters…………………………………………………………………35

Discrete Parameters………………………………………………………………….35

Boolean Parameters………………………………………………………………….35

String Parameters……………………………………………………………………35

Output Setting and Operation Commands…………………………………………..36

Trigger Commands………………………………………………………………….36

System-Related Commands…………………………………………………………36

Calibration Commands………………………………………………………………37

Status Reporting Commands……………………………………………………….37

RS-232 Interface Commands……………………………………………………….38

Simplified Programming Overview…………………………………………………38

Using the APPLy Command……………………………………………………….38

Using the Low-Level Commands………………………………………………….38

Selecting a Trigger Source…………………………………………………………39

Using the APPLY Command………………………………………………………39

Output Setting and Operation Commands………………………………………….40

Measurement Commands…………………………………………………………..40

Output on/off and Tracking Operation Commands………………………………….41

Output Setting Commands………………………………………………………….41

Trigger Source Choice………………………………………………………………43