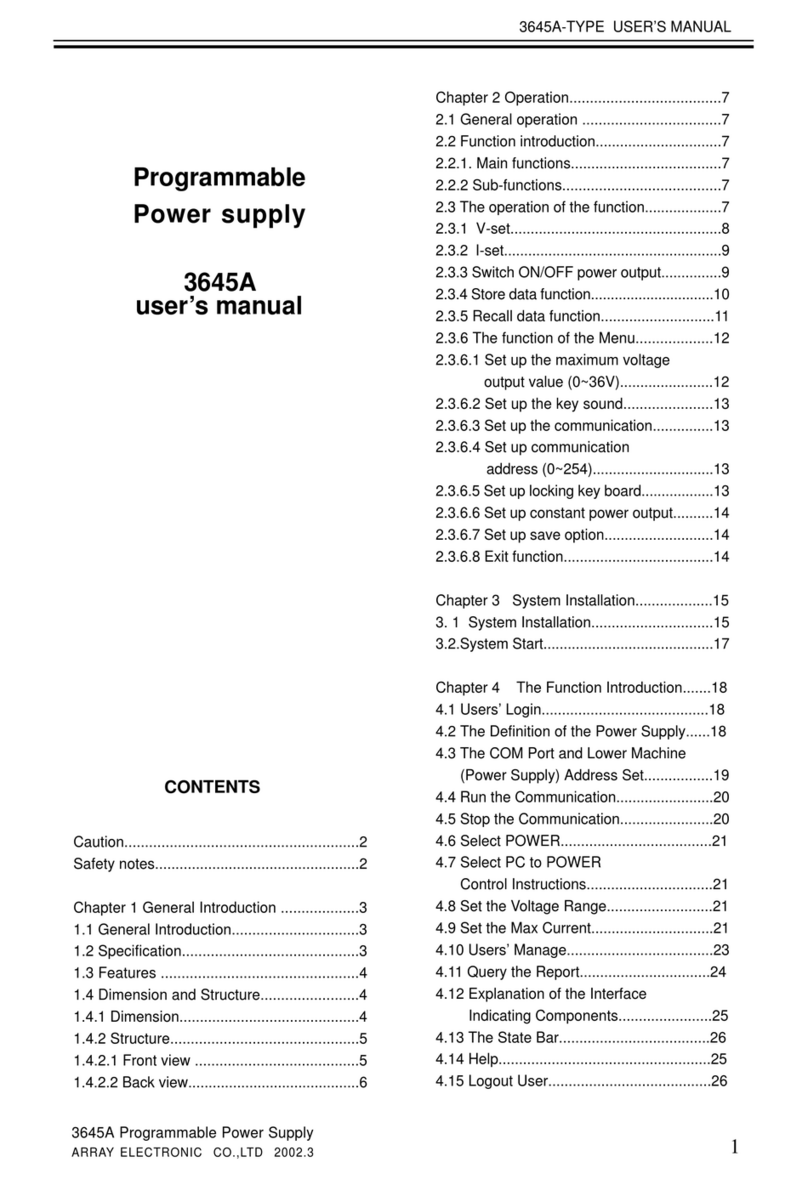

Contents

Contents

Safety Instruction …………………………………...…….....................................................1

Chapter I General Introduction ……………………………………………………...……..3

1.1 Function Features …………………………………………………………..……………3

1.2 Front Panel …………………………………………………………………….....……...4

1.3 Rear Panel ……………………………………………………………….……………....5

1.4 Keypad Function ………………………………………………………………..……….5

1.5 Annunciators ……………………………………………………………………..……...7

1.6 Display ………………………………………………………………….……………….8

1.6.1 Main Menu List ………………………………………………………………………8

1.6.2 Port Conguration Menu ………………….…………………………………………9

1.6.3 Transient Operation Menu ……………………………………………….…………10

1.6.4 List Operation Menu ………………………………………………….…………….11

1.6.5 Basic Mode Menu & LCD Information ……………………………………………..13

1.6.5.1 CC Mode Menu ………………………………………………………………….13

1.6.5.2 CR Mode Menu ……………………………………………………………….....14

1.6.5.3 CV Mode Menu ………………………………………………………………….15

1.6.5.4 CP Mode Menu …………………………………………………………………..16

1.6.5.5 +CV Mode Menu ………………………………………..………………………18

1.6.6 Error & Alarm Menu ………………………………………………………………..19

1.6.7 Save Menu ……………………………………………………………………….….19

1.6.7.1 Application Save Menu ………………………………………………………….19

1.6.7.2 Recall Save Menu ………………………………………………………………..20

1.7 Remote Programming ……………………………………………………………….....20

Chapter II Functions and Features ……………………………………………………….21

2.1 Local & Remote Control ……………………………………………………………….21

2.2 Main Functions …………………………………………………………………………21

2.3 Basic Test Functions ……………………………………………………………………22

2.3.1 CC Test …………………………………………………….………………………..22

2.3.1.1 Current Setting Range ……………………………………………….…………..23

2.3.1.2 Immediate Current Level …………………………………………………….….23

2.3.1.3 Triggered Current Level …………………………………………..……………..23

2.3.1.4 Transient Current Vevel …………………………………………..……………...24

2.3.1.5 Software Current Level ……………………………….…………………………24

2.3.2 CV Test …………………………………..………………………………………….24

2.3.2.1 Voltage Setting Range …………………………………………………………...25

2.3.2.2 Immediate Voltage Level ………………………………………..……………….25

2.3.2.3 Triggered Voltage Level …………………………………………..……………..26

2.3.2.4 Transient Voltage Level ……………………………………………….……..…..26

2.3.3 CR Test …………………………………..…………………….……………………26

2.3.3.1 Resistance Setting Range ………………………………………………………...27

2.3.3.2 Immediate Resistance Level …………………………………….…..…………...27

2.3.3.3 Triggered Resistance Level …………………………………….………………..27