I-2 BA ET18, 20, 24 en* 1.5 * et18_20_24en1_5IVZ.fm

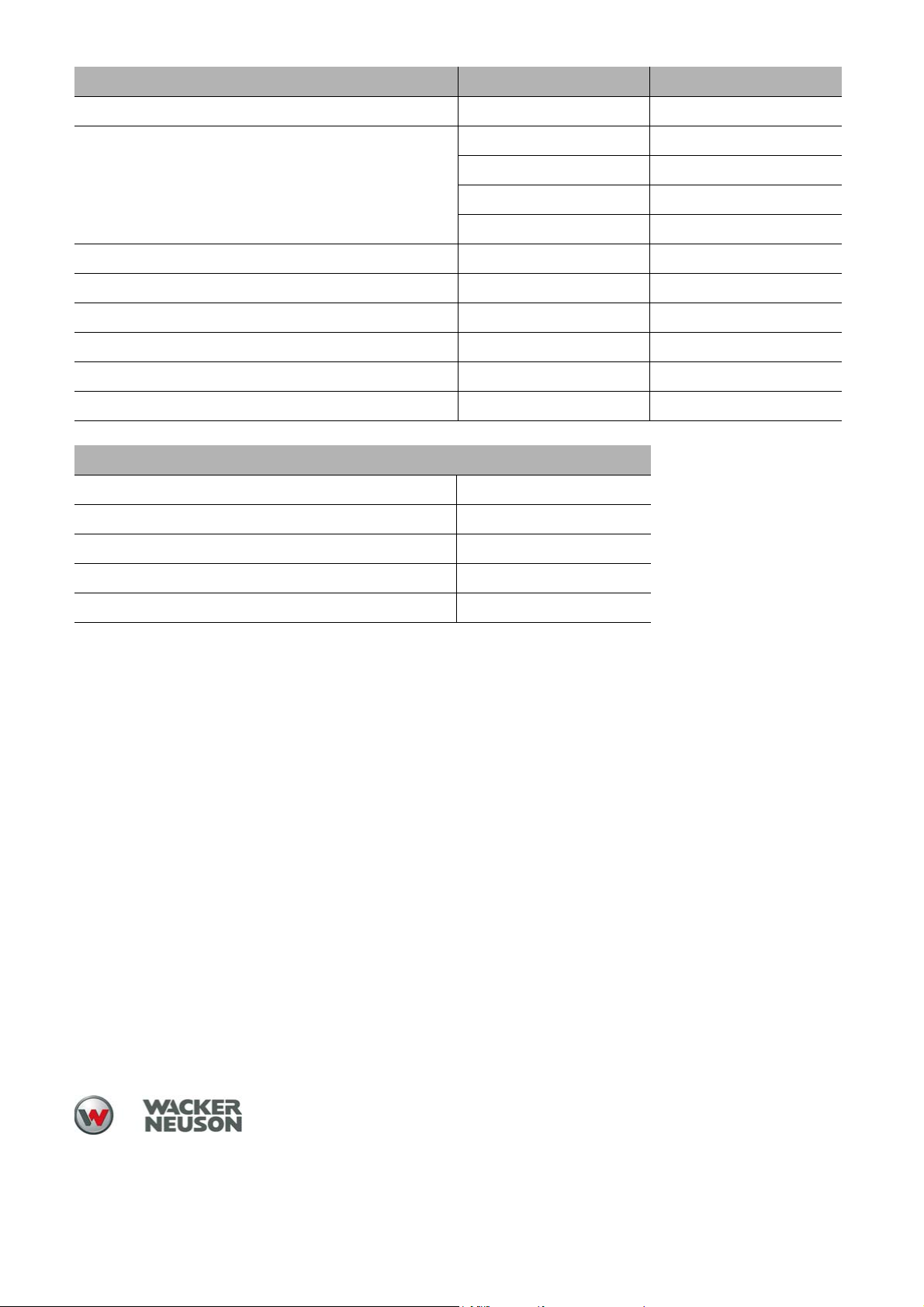

Table of contents

7 Maintenance

7.1 Information on maintenance ................................................................................................................. 7-1

7.2 Maintenance overview .......................................................................................................................... 7-2

7.3 Fluids and lubricants........................................................................................................................... 7-10

7.4 Maintenance accesses ....................................................................................................................... 7-14

7.5 Cleaning and maintenance ................................................................................................................. 7-20

7.6 Lubrication work.................................................................................................................................. 7-23

7.7 Fuel system ........................................................................................................................................ 7-26

7.8 Engine lubrication system................................................................................................................... 7-31

7.9 Cooling system ................................................................................................................................... 7-33

7.10 Air filter................................................................................................................................................ 7-36

7.11 V-belt .................................................................................................................................................. 7-39

7.12 Hydraulic system ................................................................................................................................ 7-40

7.13 Electrical system................................................................................................................................. 7-44

7.14 Heating, ventilation and air conditioning system................................................................................. 7-46

7.15 Washer system ................................................................................................................................... 7-46

7.16 Braking system ................................................................................................................................... 7-46

7.17 Tracks ................................................................................................................................................. 7-47

7.18 Maintenance of attachments............................................................................................................... 7-50

7.19 Maintenance of options....................................................................................................................... 7-50

7.20 Exhaust gas treatment........................................................................................................................ 7-51

7.21 Machine preservation ......................................................................................................................... 7-51

8Malfunctions

8.1 Diesel engine ........................................................................................................................................ 8-1

8.2 Travelling drive ..................................................................................................................................... 8-1

8.3 Hydraulic system .................................................................................................................................. 8-1

8.4 Electrical system................................................................................................................................... 8-1

8.5 Air conditioning ..................................................................................................................................... 8-1

8.6 Attachments.......................................................................................................................................... 8-2

9 Technical data

9.1 Models and trade names ...................................................................................................................... 9-1

9.2 Engine................................................................................................................................................... 9-1

9.3 Traveling drive/axles............................................................................................................................. 9-3

9.4 Brake .................................................................................................................................................... 9-3

9.5 Tracks ................................................................................................................................................... 9-3

9.6 Steering system .................................................................................................................................... 9-3

9.7 Operating hydraulics............................................................................................................................. 9-3

9.8 Electrical system................................................................................................................................... 9-5

9.9 Tightening torques ................................................................................................................................ 9-7

9.10 Coolant ................................................................................................................................................. 9-8

9.11 Noise emissions.................................................................................................................................... 9-8

9.12 Vibration................................................................................................................................................ 9-9

9.13 Weight................................................................................................................................................. 9-12

9.14 Payload/stability.................................................................................................................................. 9-14

Index

Index ..............................................................................................................................................................S-1