Simco ION Performax IQ Easy Ex User manual

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4

Performax IQ Easy Ex

Performax IQ Easy Ex Speed

Ionisatiestaaf Anti-static bar

Ionensprühstab Barre antistatique

1180

II 2 GD

Ex mb IIB T4 Gb

Ex mb IIIB T135°C Db

SIMCO (Nederland) B.V.

Postbus 71

NL-7240 AB Lochem

Telefoon +31-(0)573-288333

Telefax +31-(0)573-257319

E-mail gene[email protected]

Internet http://www.simco-ion.nl

Traderegister Apeldoorn No. 08046136

NL Gebruikershandleiding

D Bedienungsanleitung

GB User Manual

1

32

66

FR Mode d’emploi 98

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 64

CONTENTS

Preface ............................................................................................................................................. 65

Explanation of symbols ..................................................................................................................... 65

1 Introduction................................................................................................................................... 66

2 Description and Operation ............................................................................................................. 67

3 Safety ............................................................................................................................................ 68

4 Technische specificaties ................................................................................................................. 69

5 Installation .................................................................................................................................... 71

5.1 (Simplified) system overview ................................................................................................................ 71

5.2 Product Check ...................................................................................................................................... 72

5.3 Anti-static bar mounting .......................................................................................................................72

5.4 Mounting brackets (Bracket Bars) .........................................................................................................73

5.5 Montage Performax IQ Easy Ex Speed (slide bracket) ............................................................................ 74

5.6 Dissemble Performax IQ Easy Ex Speed (slide bracket) .......................................................................... 75

5.7 Alternative brackets .............................................................................................................................75

5.8 Connecting the Anti-static bar .............................................................................................................. 75

5.8.1 Connect safety earthing.................................................................................................... 75

5.8.2 Performax IQ Easy Ex Speed connection to the Ex Status module....................................... 76

5.8.3 Connecting the Ex Status Module to the IQ Easy Platform ................................................. 80

5.8.4 Connecting Ex Status Module with double safety to the IQ Easy Platform.......................... 81

6 Commissioning .............................................................................................................................. 81

6.1 Commissioning the anti-static bar through the IQ Easy Platform. ...........................................................81

6.2 Selecting EXPERT mode for setting parameters or maintenance tasks. ................................................... 82

6.3 Calibrating the Performax IQ Easy Ex through the IQ Easy Platform. ...................................................... 82

6.4 Operating modes (expert) ....................................................................................................................83

6.4.1 Operation Mode Manual .................................................................................................. 84

6.4.2 Operation mode CLFB (Closed Loop FeedBack) with IQ Easy sensor .................................... 85

6.5 Anti-static bar Standby & Active and Autorun setting. ...........................................................................85

6.6 Anti-static bar Information parameters (expert mode). ......................................................................... 86

6.7 Switching the bar on/off remotely through the remote on/off input on the Manager or via fieldbus

(expert mode) ............................................................................................................................................ 86

6.8 Datalogging (de-)activation. .................................................................................................................87

6.9 Clean bar warning level setup (expert mode) ........................................................................................ 87

7 Checking the Functionality ............................................................................................................. 87

7.1 Checking neutralization ........................................................................................................................87

7.2 Checking functionalities via the LED’s ................................................................................................... 87

7.3 Functional check via the Manager IQ Easy ............................................................................................. 88

7.3.1 Information tab ................................................................................................................ 88

7.3.2 Graphics tab ..................................................................................................................... 89

7.3.3 Action log tab ................................................................................................................... 89

7.3.4 Data log tab ..................................................................................................................... 89

7.4 Causes for overloading ......................................................................................................................... 89

8 Maintenance ................................................................................................................................. 90

8.1 Regular cleaning of the anti-static bar ................................................................................................... 90

8.2 Cleaning of a heavily contaminated anti-static bar ................................................................................ 90

9 Faults ............................................................................................................................................ 90

10 Repairs ........................................................................................................................................ 92

11 Disposal....................................................................................................................................... 92

Replacement parts ........................................................................................................................... 93

Declaration of Conformity ................................................................................................................ 95

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 65

GB

Preface

This manual concerns the installation and use of an ionization system

Performax IQ Easy Ex and Performax IQ Easy Ex Speed.

Should there be any reference in this manual to an anti-static bar then it is with reference to the

Performax IQ Easy Ex or Performax IQ Easy Ex Speed.

This manual must be available at all times to staff operating the equipment.

Read through the entire manual before installing and commissioning the product.

Follow the instructions set out in this manual to ensure proper operation of the product and to

retain your entitlement under the guarantee. The terms of the guarantee are set out in the

Simco-Ion Netherlands General Terms and Conditions of Sale.

Explanation of symbols

Warning

Indicates special information to prevent injury or significant damage to the

product or the environment.

Attention

Important information for making the most efficient use of the product

and/or for preventing damage to the product or the environment.

[ ] If icons are shown between brackets [ ], this means, depending on where

you are in the menu, it may be necessary to first select the icons between

brackets [ ] before you can go to the desired page where the follow-up

instruction are given.

Using these buttons you can scroll through the various pages.

The manual is described with the default state of the Manager: Run state Color Green =

NO.

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 66

1 Introduction

The Performax IQ Easy Ex and Performax IQ Easy Ex Speed static bars are designed to

neutralize electrostatically charged surfaces and may be used in certain hazardous areas (see

also Section 3, Safety).

The main difference between these two static bars is their recommended use;

The Performax IQ Easy Ex is suitable for general applications, the Performax IQ Easy Ex

Speed is suited for high web speeds, close to the material to be discharged.

Both static bars are equipped with an integrated high voltage power supply, emitters and a

status LED.

The Performax IQ Easy Ex and Performax IQ Easy Ex Speed are connected via a cable with 5

conductors to the IQ Easy platform. With the IQ platform the anti-static bar can be controlled

and read out centrally and remotely. Using the IQ Easy platform, the status of the bar can be

logged making quality management easier.

The Performax IQ Easy Ex is optimally deployed between 100 and 300 mm away from the

material at material speeds below 500 meters per minute and is available in effective lengths of

270 through to 2790 mm in increments of 180 mm.

For material speeds exceeding 500 meters per minute and / or material distances between 50

and 300 mm the Performax IQ Easy Ex Speed is recommended. This is available in effective

lengths from 90 through to 2790 mm, in increments of 60 mm.

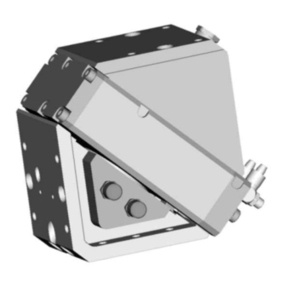

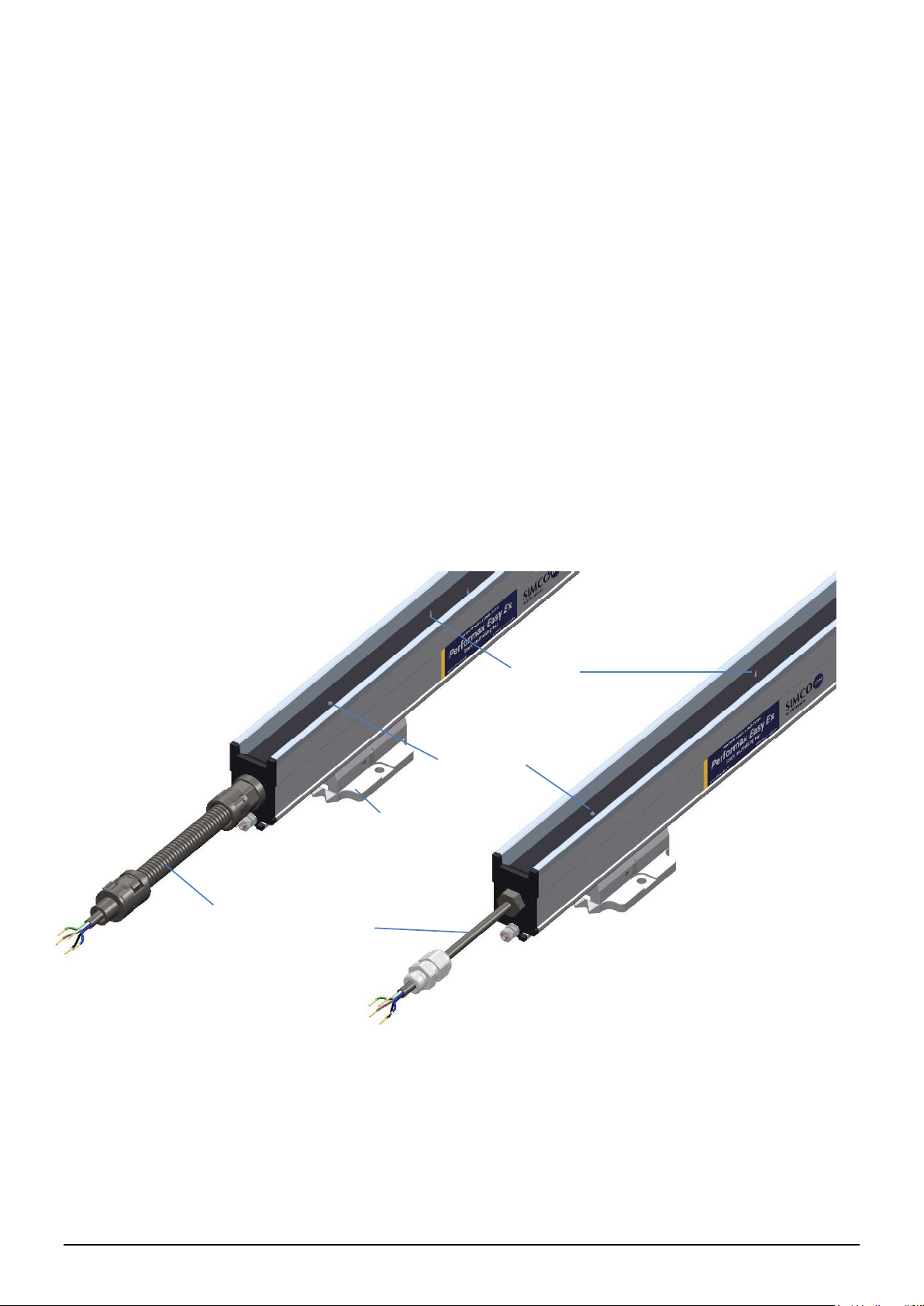

Image 1.1: Connection side Performax IQ Easy Ex and Performax IQ Easy Ex Speed

Mounting bracket

Emitters

Status LED

Fixed connecting cable,

with protective hose

(standard) or without

protective hose

(optional).

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 67

GB

2 Description and Operation

The 24 V DC power supply is converted in the anti-static bar into a positive and negative high

voltage.

The high voltage generates an electrical field at the emitters of the anti-static bar, which causes

the air molecules around the emitters to be converted into positive and negative ions. When an

electrostatically charged material comes within working distance of the anti-static bar, the ions

from the anti-static bar are exchanged with the charged material until the material is neutralized.

You can see via the status LED if the anti-static bar is in operation and if it is overloaded.

In addition, through the Manager IQ Easy divers parameters, limit values and information

concerning the functioning (efficiency) can be recorded and logged. To learn more refer also to

the user manual of the Manager IQ Easy.

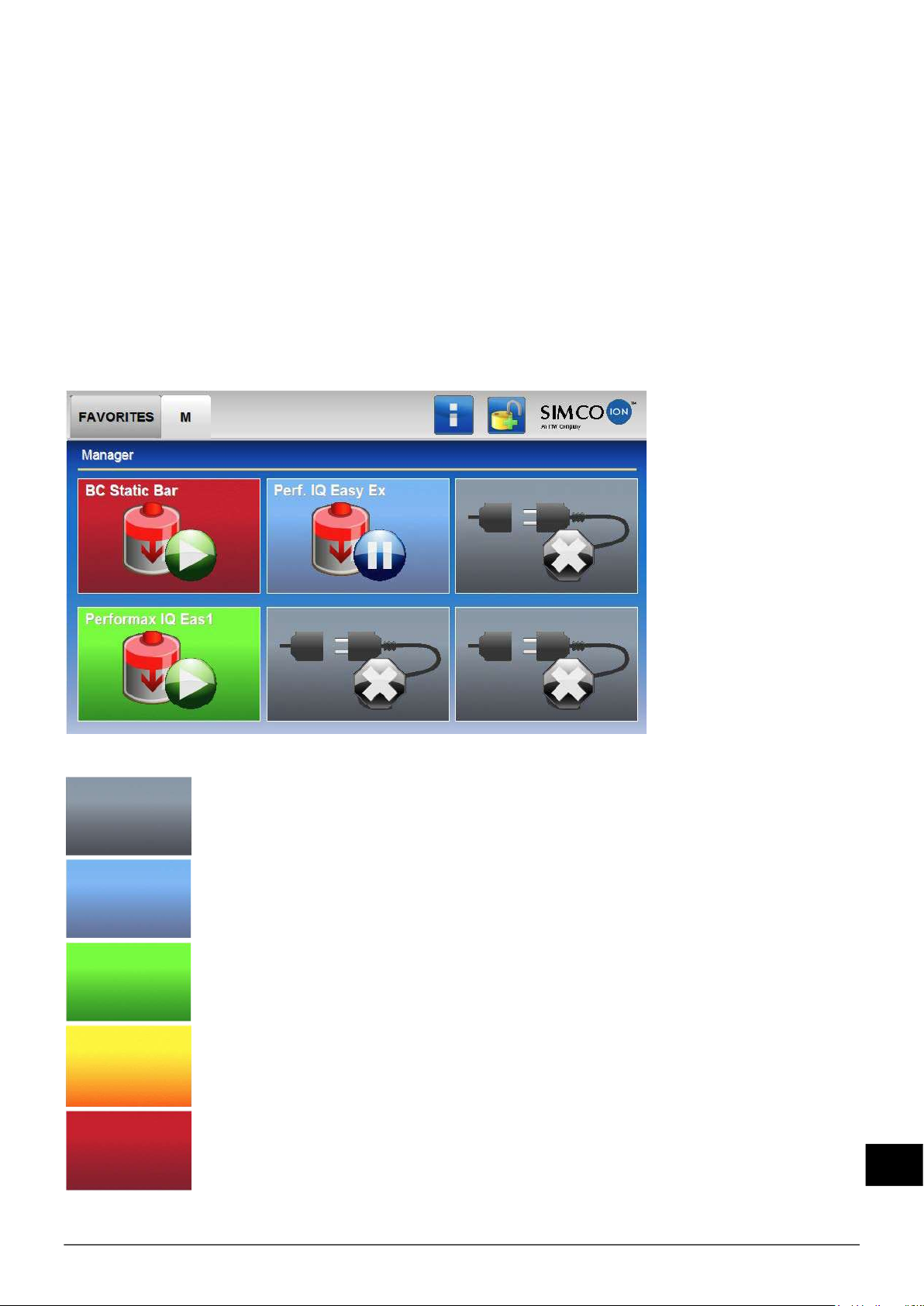

The background color of the anti-static bar icon shows the status of the anti-static bar, where:

Inactive or no communication

Active and operating OK, without warnings or alarms

Standby, waiting for start command

Active, but with a warning

Active, but with an alarm

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 68

3 Safety

The following safety guidelines must be observed in order to prevent physical injury and

damage to objects or the anti-static bar itself.

Warning:

- The anti-static bar is only intended for neutralizing electrostatically charged surfaces.

- Before using the Performax IQ Easy Ex Speed in an explosive hazardous area, check

whether it is permitted to be used in the zone classification of the hazardous area.

- The anti-static bar is suitable for ATEX II 2GD.

The anti-static bar should only be used in non-mining applications and has a “high

protection” grade:

The anti-static bar may be used in gas zones 1 and 2 and is suitable for gas groups

IIA and IIB.

The anti-static bar can be used in dust zones 21 and 22 and is suitable for use

with dust groups IIIA and IIIB.

The maximum “surface temperature “of the anti-static bar is limited to a max. 135ºC.

- The Performax IQ Easy Ex Speed should not be used in environments containing dusts

which are electrically conductive i.e. having an electrically resistivity less than 1000 ohm

meters.

- The Performax IQ Easy Ex Speed should not be used in the presence of dust having ignition

energies less than 0,2mJ.

- Mount the Performax IQ Easy Ex Speed in a manner that provides complete protection

against impact.

- Fit the connecting cable of the Performax IQ Easy Ex Speed in such a way there is no

possible mechanical damage.

- The Performax IQ Easy Ex should be mounted at a distance of 100 to 300 mm.

- The Performax IQ Easy Ex Speed should be mounted at a distance of 50 to 300 mm.

- To ensure the safe operation, the working temperature should be kept below 40ºC.

- Electrical installation should be done only by a skilled electrical engineer and in accordance

with all national and local regulations.

- Use the Performax IQ Easy Ex Speed always in combination with an Ex Status Module.

The Ex Status Module includes the necessary 0,5AT fuse with a rupturing capacity of 1500A

(70-007-33/0.5A, Siba), which should ensure safety in the event of an overload / short circuit.

Should this fuse be defective, it must be replaced with a fuse with the same properties.

- Only the Performax IQ Easy Ex Speed with fixed wiring should be installed in Ex-zone

environments. The Ex Status Module, with any other connected devices should be mounted

outside the hazardous zone.

- The equipment must be properly earthed. Earthing is essential to ensure safe operation and

to prevent electrical shock when touched.

- When working on the equipment, the equipment must be disconnected from the power

supply.

- The emitters are sharp and can cause injury.

- During the ionization process a small amount of ozone is produced. The concentration of

ozone around the emitters is dependent on many factors, such as the amount of space

around the anti-static bar and air circulation. Due to which no general value for the ozone

concentration can be given.

-

electrically safe to touch.

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 69

GB

Attention:

- The warranty for the device is void in the event that modifications, adjustments, etc. have

been made or non-original parts are used for repairs without prior written approval.

4 Technical specifications

Power Requirements

Supply Voltage 24 V DC nominal

Primary Fuse 0,5 AT, Type: 70-007-33/0.5A, Siba

This fuse has a rupturing capacity of min 1500A (breaking

capacity).

This fuse is present in the delivered Ex Status Module by Simco-

Ion.

Current consumption Max. 0,4 A DC

Connection Cable 5 x 0,34 mm2

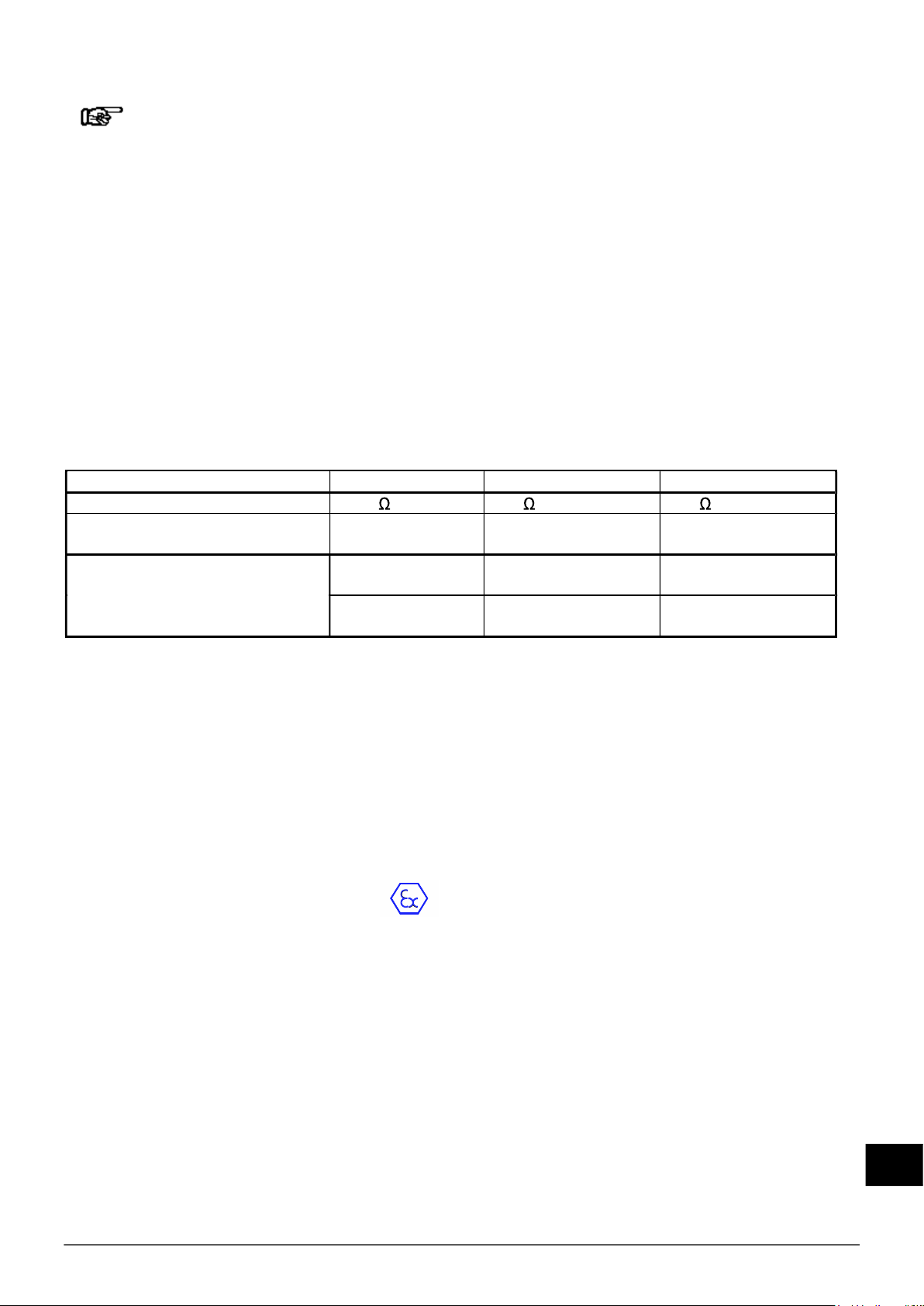

Max. total cable length @ supply 24V DC ± 2% 24V DC ± 5% 24V DC ± 10%

Max. cable resistance per wire 3,125 2,25 0,75

Standard Simco 5x0,34 mm2&

M12 Male-Female cable

62,5m 45m 15m

Type power supply 100-240 V AC

Manager IQ Easy

100-240 V AC

Extension IQ Easy

Input

Remote on/off 10 – 30 V DC nominal (Ri >10k)

Activation time 30 ms

Output

Output voltage emitters Max. 9 kV positive and negative

Current per emitter to earth Max. 50 µA

High voltage OK (HV OK) Supply voltage -1 V, max. 50 mA

Environment

Usage Industrial, indoor usage

Ex environment

ATEX II 2 GD (see Chapter 3)

Ex mb IIB T4 Gb

Ex mb IIIB T135°C Db

Protection class IP66

Ambient temperature 0 - 40°C

Max. Temperature enclosure 135°C

Material speed Performax IQ Easy Ex 0 – 500 m/min

Performax IQ Easy Ex Speed >500 m/min

Working distance Performax IQ Easy Ex

Performax IQ Easy Ex Speed

100 - 300 mm

50 – 300 mm

Local signaling

2-Color LED Continual: Blinking:

Green In use Stand-by

Red Overloaded No communication

See chapter 7 for more info

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 70

Mechanical

Effective length Performax IQ Easy Ex 270 - 2790 mm

in increments of 180 mm

Performax IQ Easy Ex

Speed

90 - 2790 mm

In increments of 60 mm

Dimensions exclusive

Mounting brackets

Tot. length= Eff. length + 250 mm (with protective hose)

Tot. length= Eff. length + 180 mm (without protective hose)

Width 30 mm

Height 52 mm

Weight 2,2 kg/m

Enclosure Aluminum / PA6 / PUR

Universal Mounting brackets PA66/6

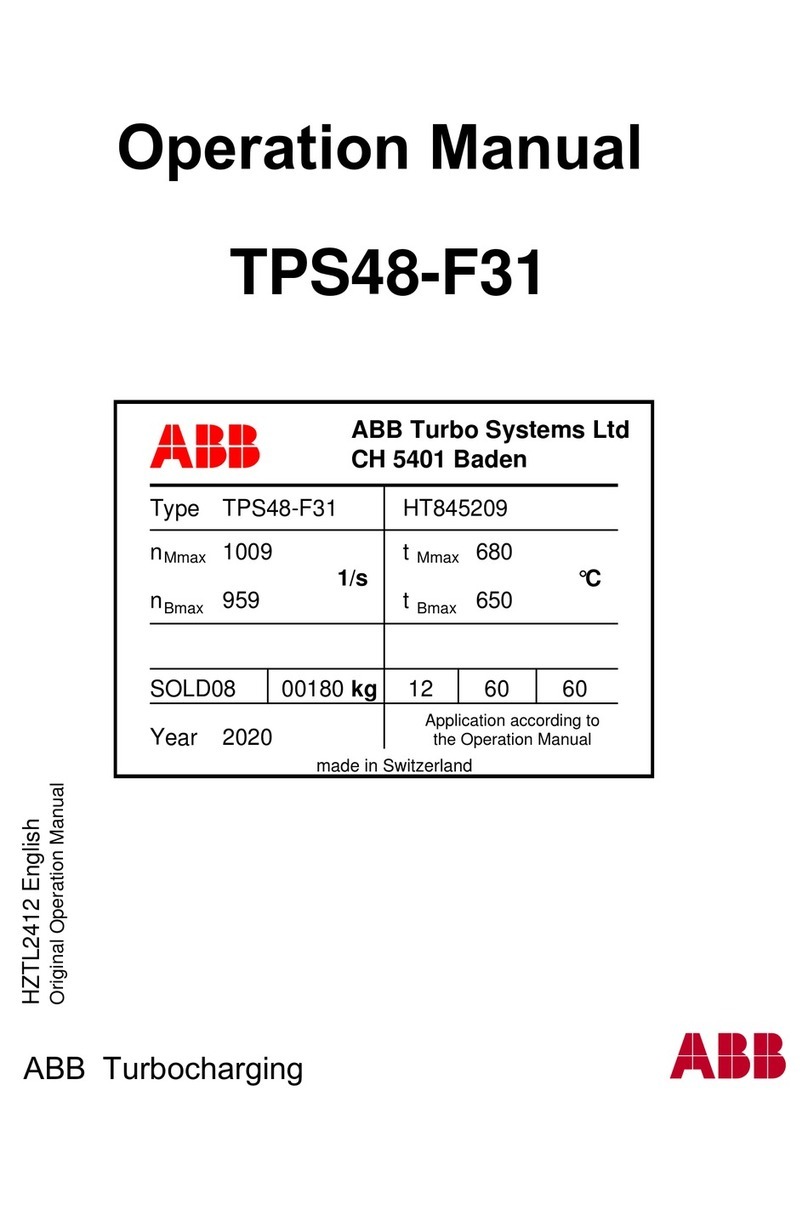

Image 4.1.1: Dimensions Performax IQ Easy Ex (Speed)

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 71

GB

5 Installation

Warning:

-Before using the Performax IQ Easy Ex Speed in an explosive hazardous area, check

whether it is permitted to be used in the zone classification of the hazardous area.

-Mount the Performax IQ Easy Ex Speed in a manner that provides complete protection

against impact.

-Only the Performax IQ Easy Ex Speed with fixed wiring can be installed in the

hazardous area. The Ex Status Module and any other connected devices must be

mounted outside the Ex zone.

-Electrical installation and repairs must be done only by a skilled electrical engineer

and in accordance with all national and local regulations.

-When working on the equipment, the equipment must be disconnected from the

power supply.

-The equipment must be properly grounded. Earthing is necessary to ensure safe

operation and to prevent any electrical shock when touched.

-Connect the ground terminal on the anti-static bar to a grounded part of the machine

with a wire of a minimum size of 4mm2.

-Use the Performax IQ Easy Ex Speed always in combination with the Ex Status

Module and IQ Easy Manager and / or Extension IQ Easy.

The anti-static bar is powered and controlled via the IQ Easy Platform.

See the list of spare parts and accessories for the available IQ Easy Managers and Extension

IQ Easy.

5.1 Simplified system overview

A Status Module is needed for each anti-static bar. The anti-static bar is connected to the Status

Module through the wires at a connector block in the Status Module. For instructions, see 5.8.2.

The Status Module is connected with the Manager IQ Easy.

5.2 Product Check

- Make sure the equipment is undamaged and that the correct version is received.

- Make sure the packing slip corresponds with the data of the received product.

Should you have any problems and / or questions, please contact Simco-Ion or the local agent

in your area.

Image 5.1.1: System overview

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 72

5.3 Anti-static bar mounting

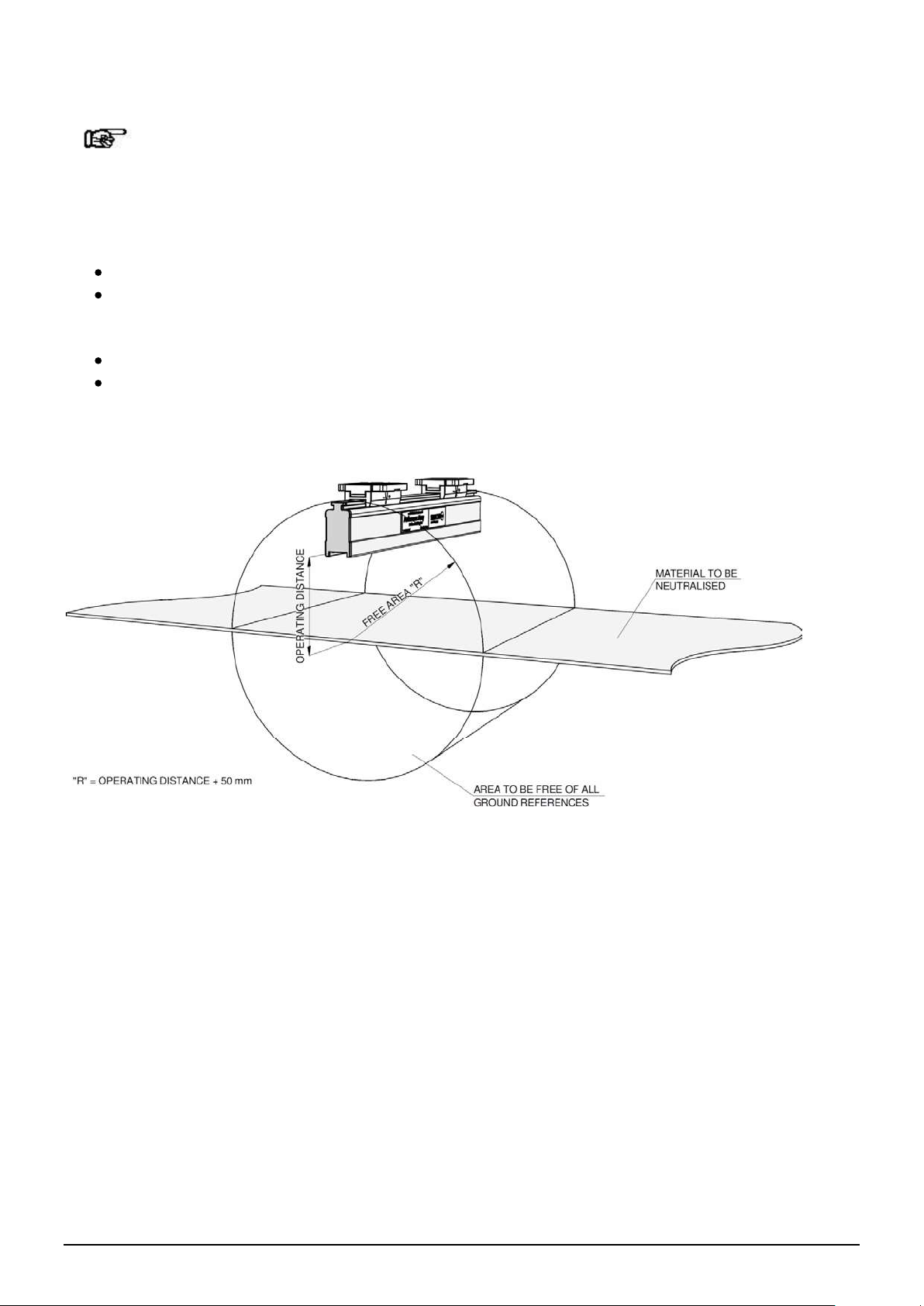

Attention:

- Any conductive machine parts in the vicinity of the anti-static bar will negatively affect

its performance. For the best results the anti-static bar should be mounted in

accordance with Image 5.3.1

- Mounting the anti-static bar:

Place just before the location where the static electricity problem occurs.

Place with an optimal distance from the material that should be neutralized:

o100 - 300 mm (Performax IQ Easy Ex)

o50 - 300 mm (Performax IQ Easy Ex Speed)

With the emitters in the direction of the material to be neutralized.

Ensure that no material can come between the emitters and the material to be neutralized

Attach the cable properly into the machine to prevent mechanical damage (suitable hose

and clamps can be ordered separately).

Image 5.3.1: Optimal position Performax IQ Easy Ex and Performax IQ Easy Ex Speed

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 73

GB

5.4 Mounting brackets

The anti-static bars are provided with at least two mounting brackets with which the anti-static

bars can be attached in many different ways.

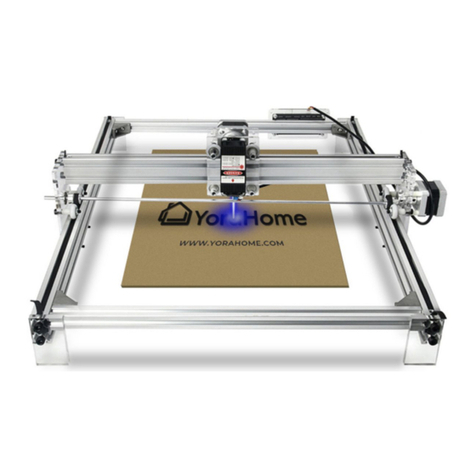

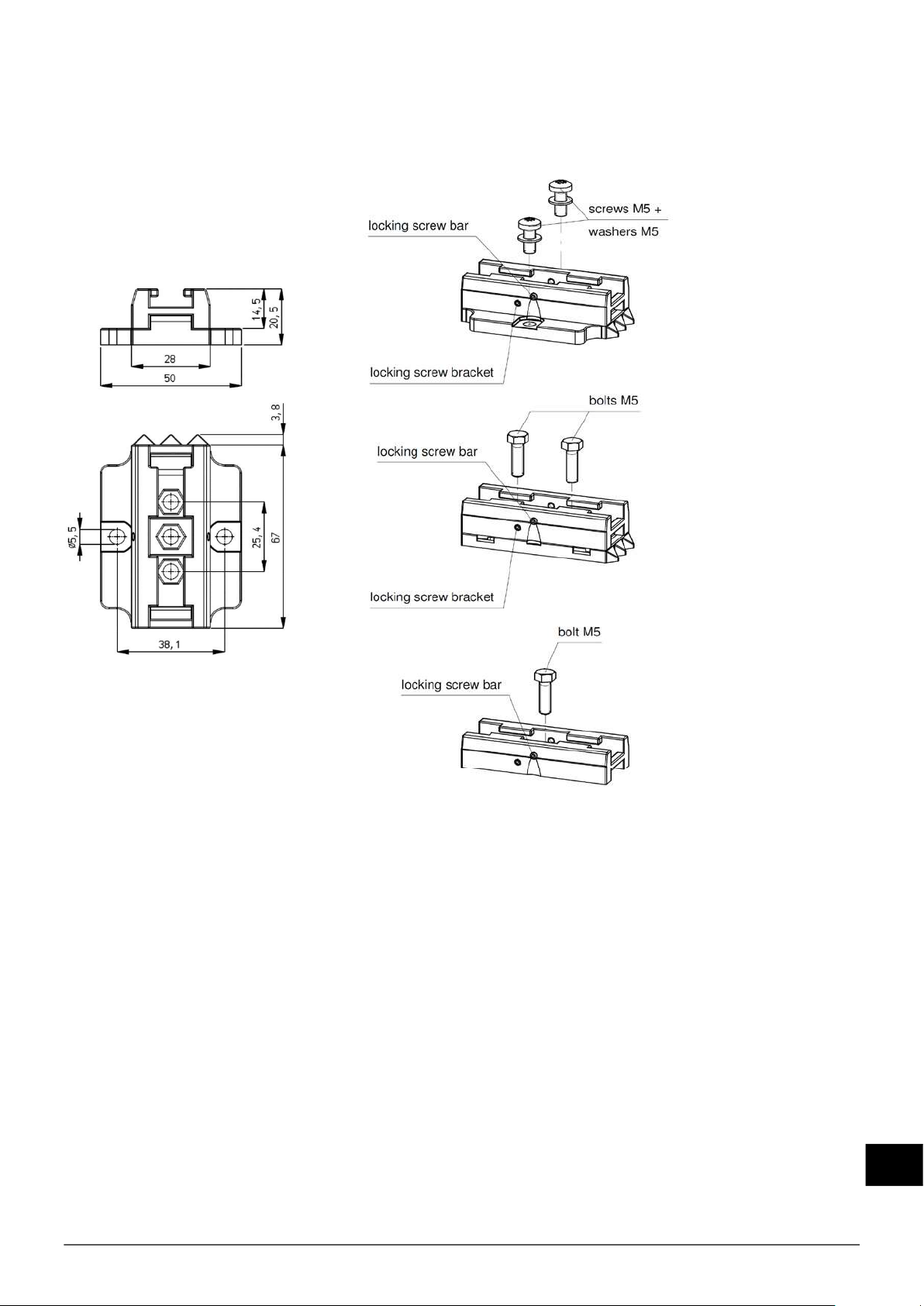

Image 5.4.1: Mounting brackets Performax IQ Easy Ex Speed dimensions and mounting options

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 74

5.5 Montage Performax IQ Easy Ex Speed (slide bracket)

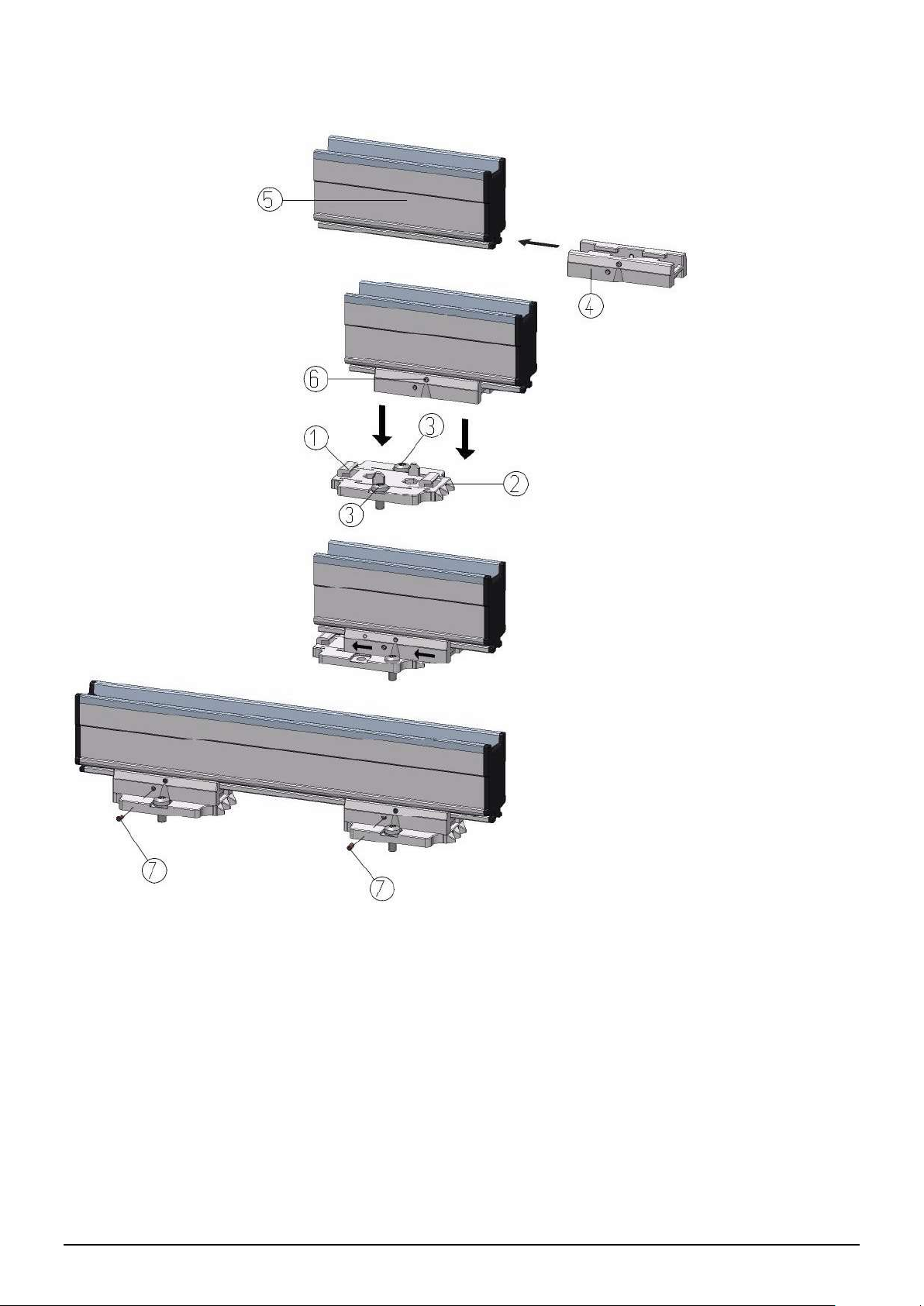

Image 5.5.6: Fixing the anti-static bar with mounting brackets

- Mount the mounting feet (1) on the machine, with the triangles (2) pointing in the same

direction. Use suitable M5-fixing materials (3).

- Slide the brackets (4) on the anti-static bar (5).

-Place the anti-static bar with brackets on the mounting feet and push the brackets (4) in the

opposite direction of the three triangles.

- Lock the bracket (4) by tightening at least one of the two set screws (7) (a screw is on both

sides).

- Position the ionization points above the material to be neutralized.

- Secure the anti-static bar (5) with a screw (6).

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 75

GB

5.6 Dissemble Performax IQ Easy Ex Speed (slide bracket)

- Remove the connection cable from the Ex Status Module.

- Unscrew the set screw (no. 6) from the brackets (see Image 5).

- Slide the anti-static bar with brackets from the mounting feet, in the direction of the three

triangles (Mounting method) till it stops, pull the anti-static bar perpendicular to the mounting

feet.

5.7 Alternative brackets

As an alternative to the plastic brackets, 2 additional stainless steel types are available:

5.8 Connecting the Anti-static bar

Warning:

- Observe the warnings at the beginning of this chapter.

- The Ex Status Module must be mounted outside the Ex zone.

-Use the Performax IQ Easy Ex Speed always in combination with an Ex Status Module.

Never connect the Performax IQ Easy Ex Speed directly to the power supply, this is

because the Ex Status Module contains the required fuse (0,5 AT / 1500A breaking

capacity)

5.8.1 Connect safety earthing

Connect the anti-static bar with an M4 eyelet and a grounding wire of at least 4 mm² to a

grounded machine part or grounded terminal.

Image 5.8.1.1: Connecting grounding

Image 5.7.1: Bracket T-slot stainless steel

Image 5.7.2: Bracket thread M6x35 stainless steel

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 76

5.8.2 Performax IQ Easy Ex Speed connection to the Ex Status module

Mount the Status Module at a place outside the EX-Zone.

Use 2 bolts or screws of a max. 4 mm. Take into account 15 cm of space for the cable

connection from the EX anti-static bar on one side, and the cable with connector on the other

side. Also note that the LED next to the connector should be visible in order to view the status of

the anti-static bar.

For an EX-bar with protective hose:

- When needed: cut the 5-wire cable to the desired length.

- Cut the protective hose on the needed length. This is the cable length - 32mm (see image

5.8.2.3).

- Push a yellow seal on the protective hose on the bar side. (see image 5.8.2.4).

- Run the cable through the protective hose with the yellow seal at the bar side.

- Push the protective hose into the fitting of the ionization bar until the yellow seal is no longer

visible (see image 5.8.2.5).

- Insert the grey clip into the fitting with the slot facing the outside, so it can be removed with a

screw driver if required (see image 5.8.2.6).

- Push a yellow seal on the protective hose on the status module side

- When needed: strip the cable according picture 5.8.2.7 mount proper ferrules (within

shipment) to the end of the wires.

- Screw the fitting into the Status Module and run the stripped cable through the fitting.

- Push the protective hose into the fitting of the ionization bar until the yellow seal is no longer

visible (see image 5.8.2.8).

- Insert the grey clip into the fitting with the slot facing the outside, so it can be removed with a

screwdriver if required.

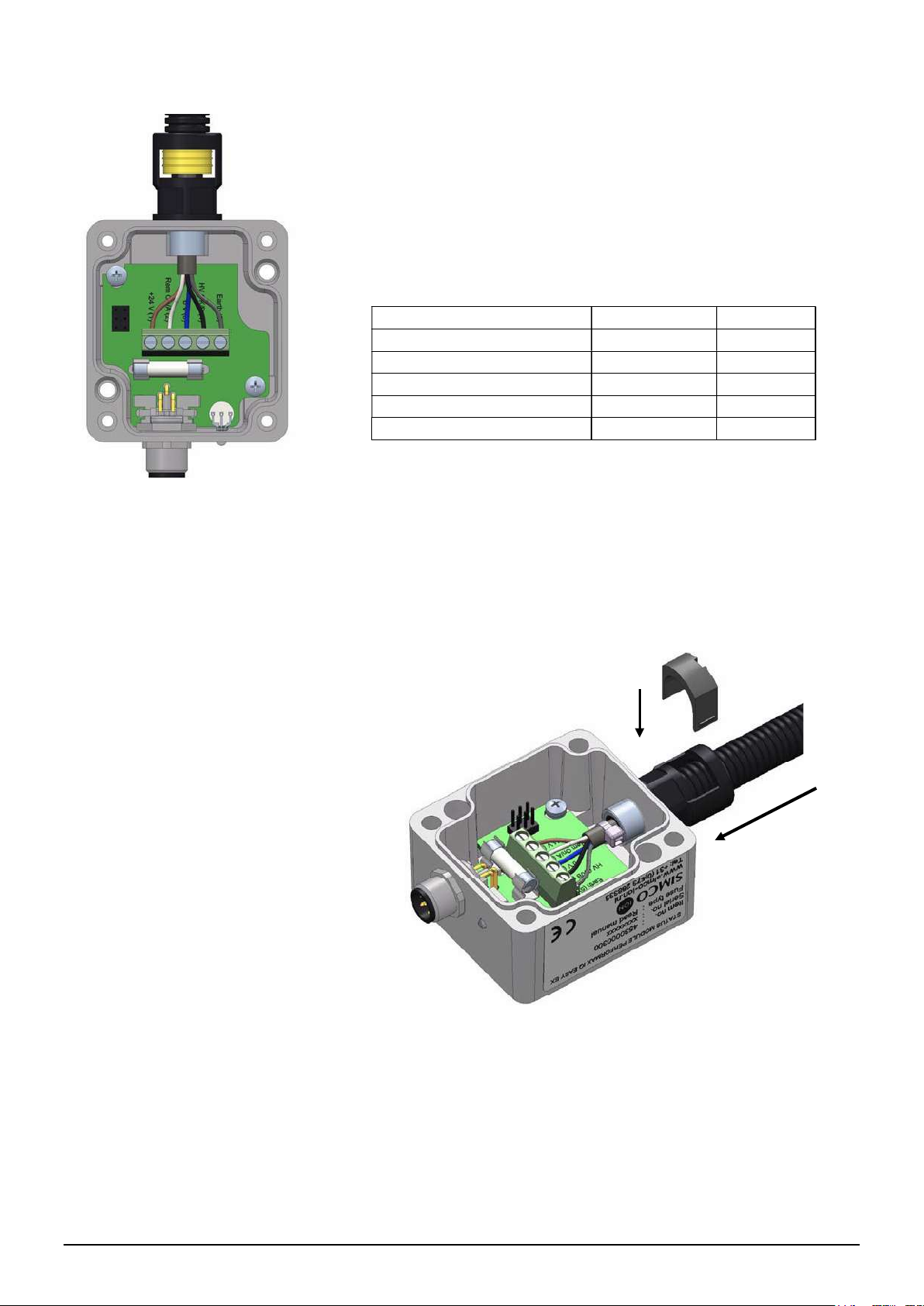

- Connect the cable to the pcb of the Status Module.

Remove the cover of

the Status module

and remove the

blind plug.

Image 5.8.2.1: Prepare connection Status Module

Image 5.8.2.2: Sizes of fixing holes Status Module

LED

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 77

GB

Image 5.8.2.3 Length protective hose

Image 5.8.2.4: Yellow seal on protective hose

Image 5.8.2.5: Protective hose in fitting Image 5.8.2.6: Clip in fitting

Image 5.8.2.7: Strip the cable

Image 5.8.2.8: Mounting of fitting on Status Module

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 78

Push the protective hose into the Status Module until the yellow

seal is no longer visible (1). Then insert the grey clip in the fitting

with the slot facing the outside (2),

so it can be removed with a screw driver if required.

Then replace the cover and fasten with the screws.

Colour: Connection: Number:

Brown + 24 V 1

White A 2

Blue 0 V 3

Black B 4

Yellow/green or grey Earth 5

Image 5.8.2.10: Fixing a protective hose to the fitting

1

2

Connect the cable according to the table below

:

Image 5.8.2.9: Connection wiring Performax Easy EX Speed with the Status Module

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 79

GB

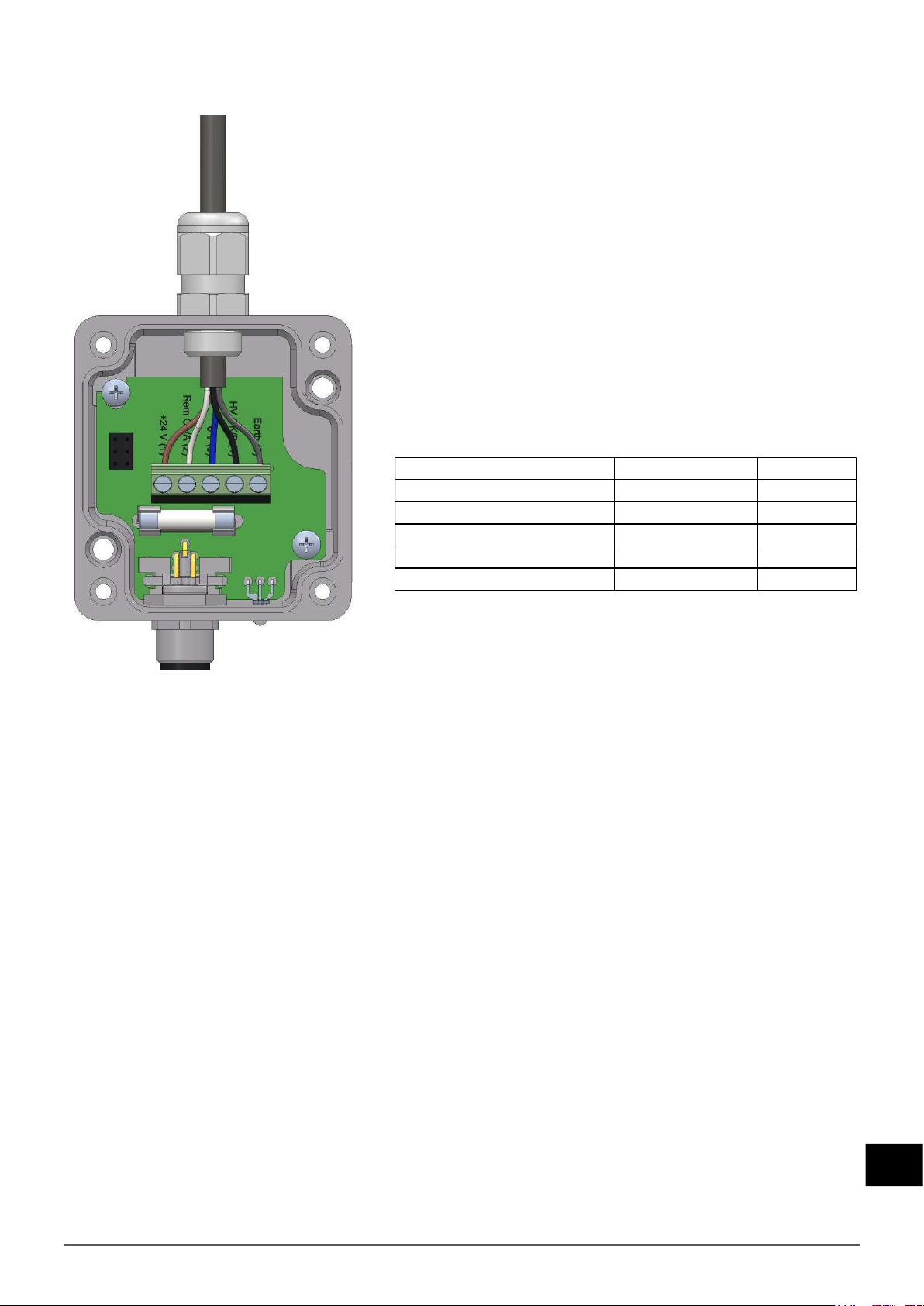

Colour: Connection: Number:

Brown + 24 V 1

White A 2

Blue 0 V 3

Black B 4

Yellow/green or grey Earth 5

For an EX-bar with cable without protective hose:

When needed: cut the cable to the desired length, strip

the cable according to figure 5.2.8.7 and mount proper

ferrules to the end of the wires.

Turn the gland in the Status Module and run the cable

through the gland. Tighten the clamp ring of the bolt for

good sealing and relief from straining.

Connect the cable according to the table below, place

the cover and screw tightly.

Image 5.8.2.11: Wiring connection Performax Easy EX (Speed) with Status Module

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 80

5.8.3 Connecting the Ex Status Module to the IQ Easy Platform

- Connect the Ex Status Module via a 1:1 M12 connection cable, Male-Female, 5 pins to one

of the outputs of the Manager IQ Easy or Extension IQ Easy.

The standard M12 connector can be connected during operation of the IQ Manager Easy.

Hence, it doesn’t need to be switched off!

Image 5.8.3.2: Wiring connectors

brown

blue (GND)

yellow/green or grey

brown

black

whitewhite

yellow/green or grey

black

blue

Ex Status Module)

(cable side view)

Female connector M12

Manager / Extension IQ Easy

(cable side view)

Male connector M12

2

white

1

brown 5

yellow/green

or grey

3 blue

4 black

2

white

3 blue

5

yellow/green

or grey

1

brown

4 black

Image 5.8.3.1: Connecting Status Module to Manager IQ Easy

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 81

GB

5.8.4 Connecting Ex Status Module with double safety to the IQ Easy Platform

In the event that power supply from the anti-static bar by means of a double safety connection is

required, it can be arranged as follows:

6 Commissioning

Attention:

- The anti-static bar does not work if the emitters are covered.

-Remove the protective cover. The cover is used solely to protect the emitters during

transport and mounting.

6.1 Commissioning the anti-static bar through the IQ Easy Platform.

In the event that the message ”Undefined param” appears on the info screen from the

bar on the Manager or when the bar is not reqognized, the Manager must be updated with

the latest software.

Download the latest software-version via www.simco-ion.co.uk/software

and follow the "Upgrade" instructions as described in the Manager manual.

-When the M12 connection cable connects the anti-static bar and the IQ Easy platform,

communication will be established automatically, this is indicated by the flashing status of the

LEDs.

By default, the bar will activate after all information has been gathered by the Manager. This

is indicated by the background color changing to Blue.

See also the user manual for the Manager IQ Easy for a general explanation.

Image 5.8.4.1: Connecting Status Module to Manager IQ Easy with safety relays

PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4 82

The anti-static bar will now ionize.

6.2 Selecting EXPERT mode for setting parameters or maintenance tasks.

In order to set parameters and carry out maintenance, you need expert user privileges. A

password may be required. For a detailed description, please refer to chapter 6.4 from the

Manager IQ Easy manual.

Once logged in at this user level, you will remain at this level until a new level is selected.

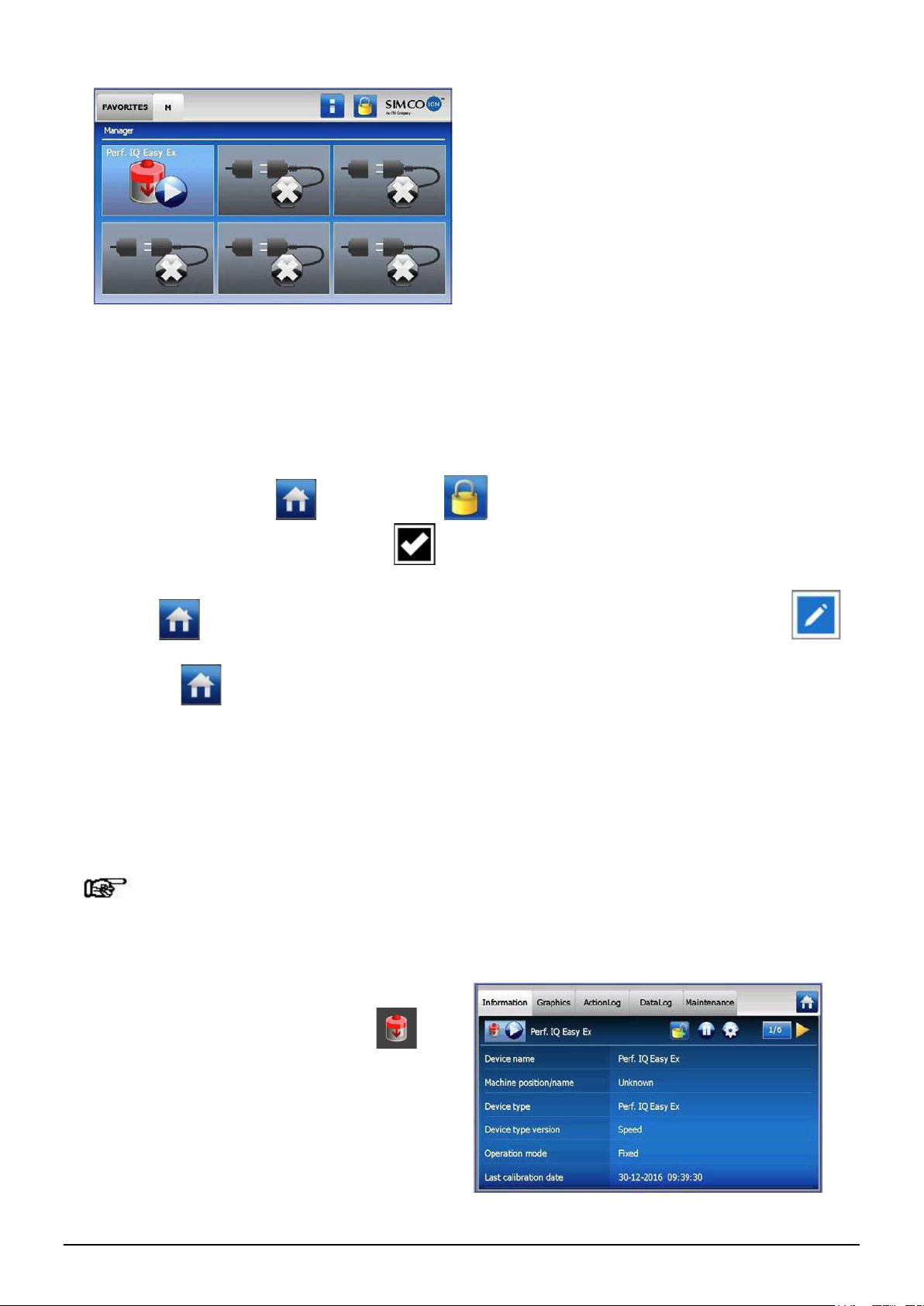

-Go to the main screen select settings and choose expert.

-Enter the password and confirm with or return directly to the system settings page of

the Manager, if no password is required.

-Click on and go to the device to check or change the parameters by clicking on

behind the parameter or desired action.

-By clicking you will return to the main screen.

6.3 Calibrating the Performax IQ Easy Ex through the IQ Easy Platform.

The anti-static bar should be calibrated when:

- It is first commissioned,

- The position of the bar is changed

- Following cleaning.

Attention:

Make sure that the bar is mounted in the final position and that the conveyor or object to be

neutralized is in position but not moving (standing still).

.

-Go to user level expert section – see 6.2

- Go to the device menu by clicking

This manual suits for next models

1

Table of contents