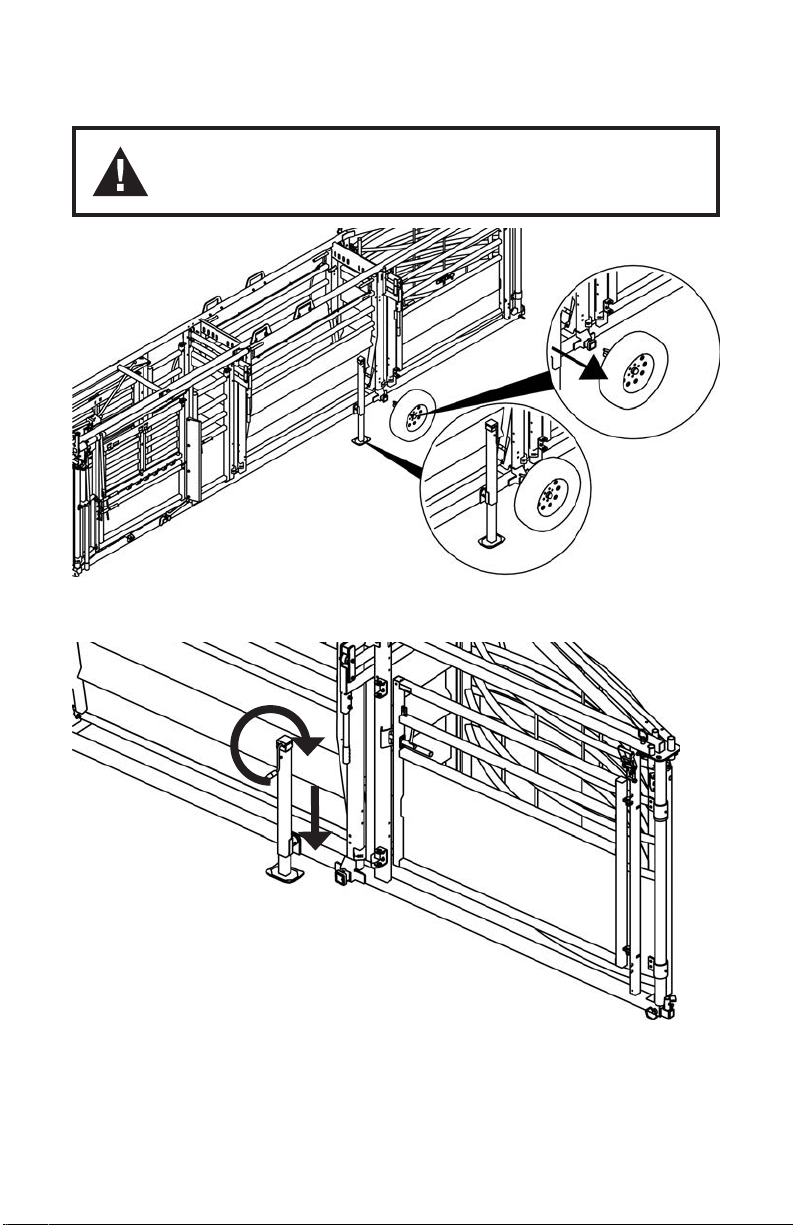

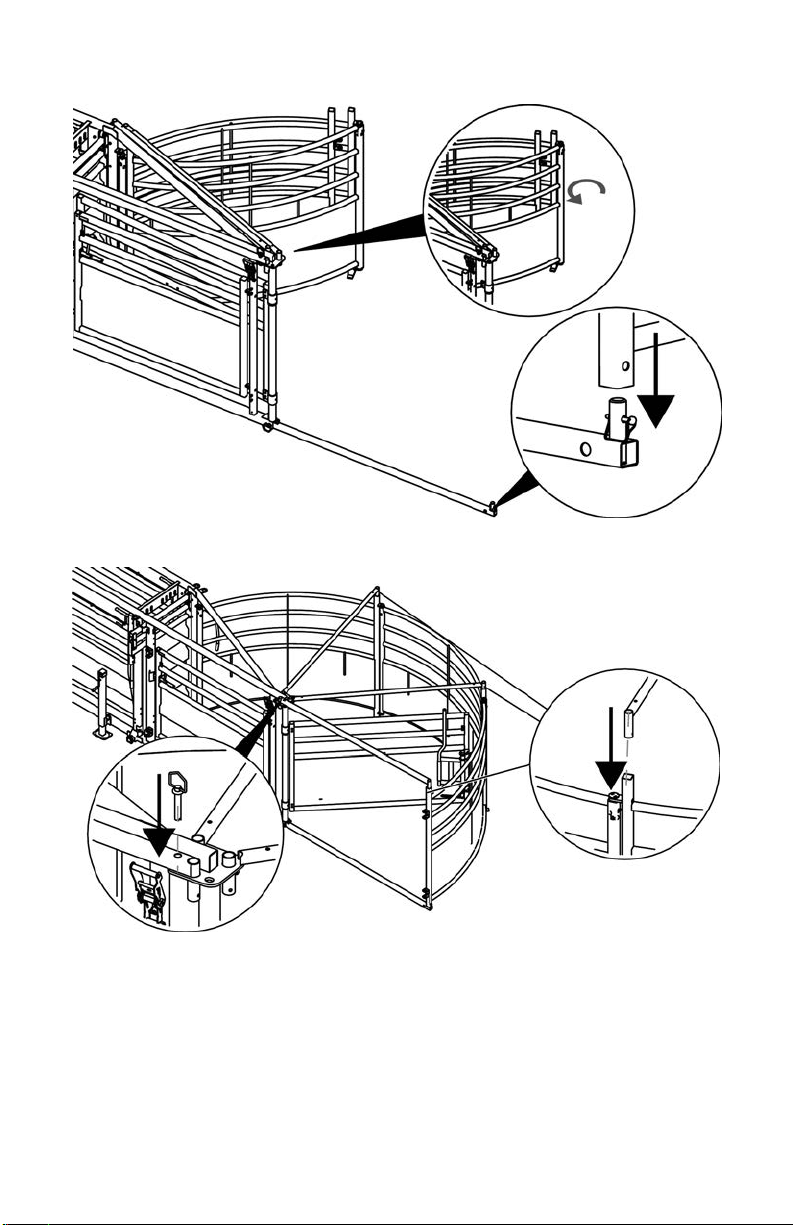

PLEASE FOLLOW ALL SAFETY INSTRUCTIONS PROVIDED IN THIS MANUAL

BEFORE OPERATION. ARROWQUIP DOES NOT ACCEPT RESPONSIBILITY

FOR ANY ACCIDENTS OR INJURY WHEN THIS SAFETY MANUAL HAS

NOT BEEN READ IN FULL AND KEPT WITH THE PRODUCT AT ALL TIMES.

OPERATORS OF THIS PRODUCT TAKE AND ACCEPT RESPONSIBILITY FOR

ANY HARM OR INJURY TO THE ANIMAL OR OPERATOR WHEN IT PERTAINS

TO HOW THE EQUIPMENT IS USED AND MAINTAINED.

Please keep this manual for frequent reference and to pass on to new users or owners.

SAFETY PRECAUTIONS

PLEASE FOLLOW ALL SAFETY PRECAUTIONS OUTLINED HEREIN. ANY

HARM TO THE ANIMAL OR INJURY TO THE OPERATOR WHICH OCCURS

DUE TO HOW THE PRODUCT IS OPERATED, OR RESULTING FROM A

LACK OF SAFETY PRECAUTIONS ARE THE SOLE RESPONSIBILITY OF

THE OPERATOR.

All farm machinery and equipment is potentially dangerous. Careless use of any Arrowquip

livestock equipment may cause injury or damage to persons, cattle, or property. Arrowquip has

taken precautions in the design and manufacturing of this product to ensure that it is safe and user-

friendly. Therefore, user must assume all responsibility and risk associated with the possession

and use of the equipment.

WARNING: READ BELOW BEFORE OPERATION.

1. Ensure the operator understands the contents of this manual before using the equipment.

2. DO NOT wear loose-tted clothing.

3. Ensure the equipment is on a rm, level, dry surface that is free of rocks and other trip

hazards.

4. DO NOT enter the vet cage until the animal is secured in the yoke gate.

5. DO NOT stand in front of the yoke gate while operator is moving the cattle through the

cattle crush.

6. DO NOT ALLOW CHILDREN UNDER THE AGE OF 18 NEAR AN OPERATING MACHINE.

7. Follow safe cattle handling procedures in other areas of the yard so that cattle are more

docile.

8. DO NOT make any modications to Arrowquip equipment. Non-factory modications to the

equipment can reduce the safety for the operator and livestock.

1 | SAFETY PRECAUTIONS