RISK ASSESSMENT |3

5. DO NOT ALLOW CHILDREN UNDER THE AGE OF 18 NEAR AN OPERATING

MACHINE.

6. Follow safe cattle handling procedures in other areas of the yard so that cattle are

more docile in the chute.

7. DO NOT

and void warranty.

8. DO NOT ALLOW CHILDREN UNDER THE AGE OF 18 TO USE THE HYDRAULIC

EQUIPMENT.

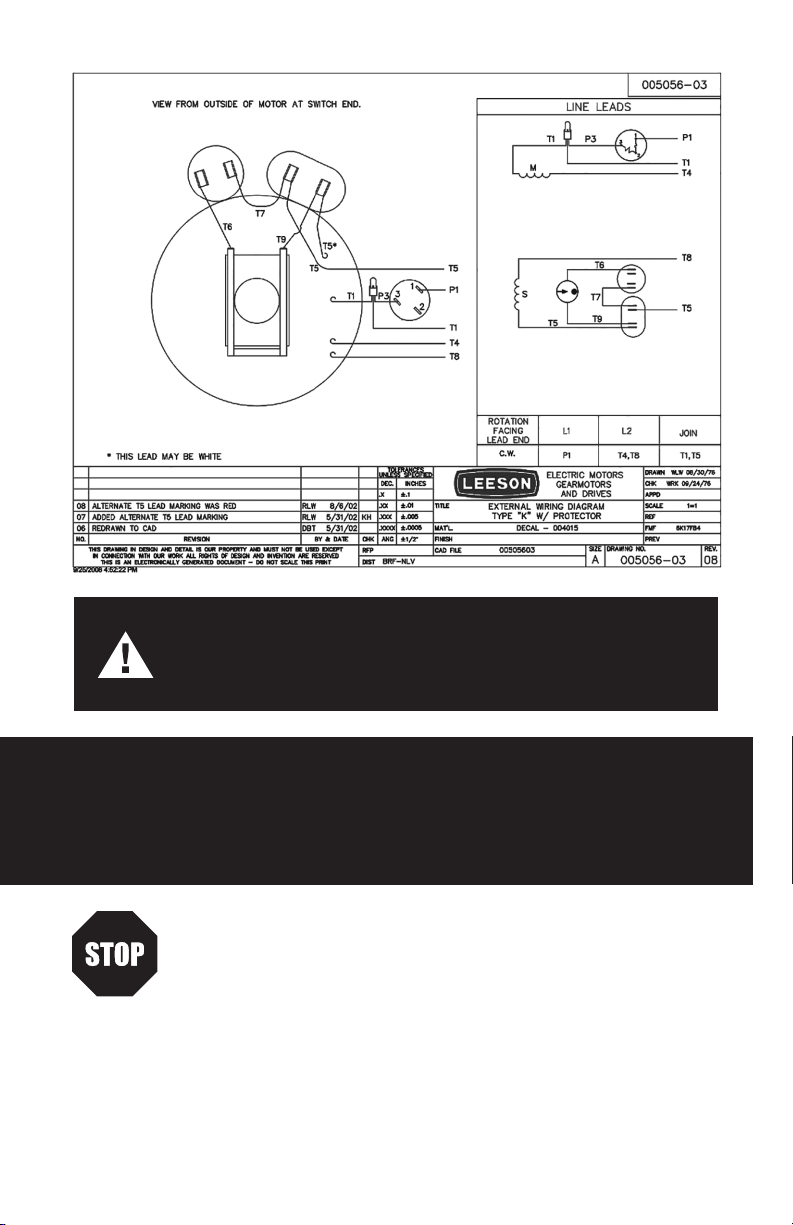

9. DO NOT OPERATE HYDRAULICS WHILE OPERATORS ARE WORKING WITH THE

CATTLE IN THE CHUTE OR ARE TOUCHING THE CHUTE. REACHING OUT OR INTO

THE CHUTE WHILE HYDRAULICS ARE IN OPERATION CAN RESULT IN SERIOUS

INJURY.

10. Please ensure that all hydraulic hoses and electrical leads are out of the way and

safely positioned before moving cattle or using the chute.

11. Keep a distance of more than an arm’s length from the hydraulic chute while

hydraulics are in operation.

12. When using the Emergency Side Exit, exercise caution. Improper placement of the

swing arm may result in injury to the operator or damage to the equipment.

13. When using V-Squeeze setting on small calves, be cautious with the amount of

pressure may cause leg/hoof damage.

14. Stay alert when using side exit doors and bottom swing-out gates on uneven

ground or V-Squeeze/A-Squeeze settings, as doors may open/close on their own.

15. When using the drop-down side access panels, ensure the latch is fully engaged to

prevent the panels from dropping when under pressure.

16. When closing doors, ensure latching pins move freely, so that they will fully engage

in the latch catches and function properly.

RISK ASSESSMENT

Conduct a risk assessment on procedures regarding the operation of an Arrowquip

hydraulic squeeze chute, establishing a safe work procedure.

1. Ensure all users of the equipment have been inducted and comply with safe

working procedures.

2.

3. Please ensure that there are no hydraulic hoses or large objects within or around

the chute where cattle and operator will be.

4. Please ensure that all hydraulics work properly before putting cattle through the

chute.