use and maintenance manual

3

TABLE OF CONTENTS

EC DECLARATION OF CONFORMITY.............................................................................................................................................................2

INTRODUCTION.................................................................................................................................................................................................5

A1

I

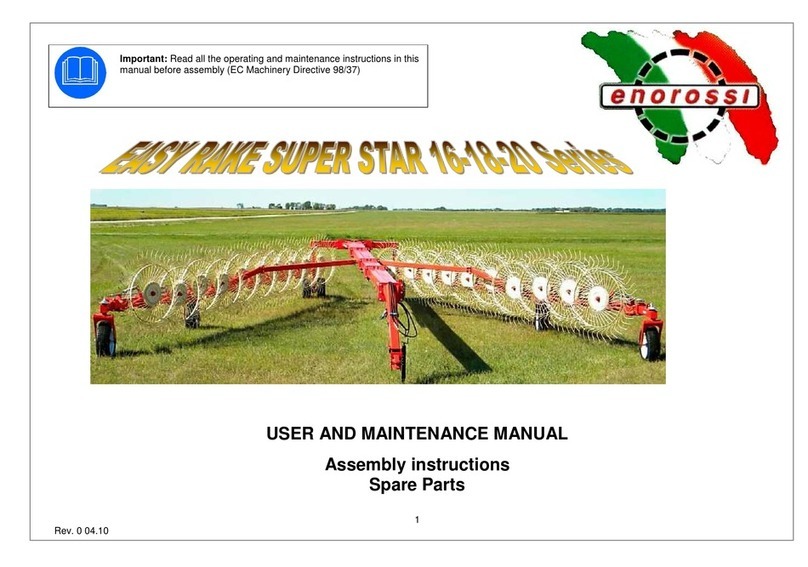

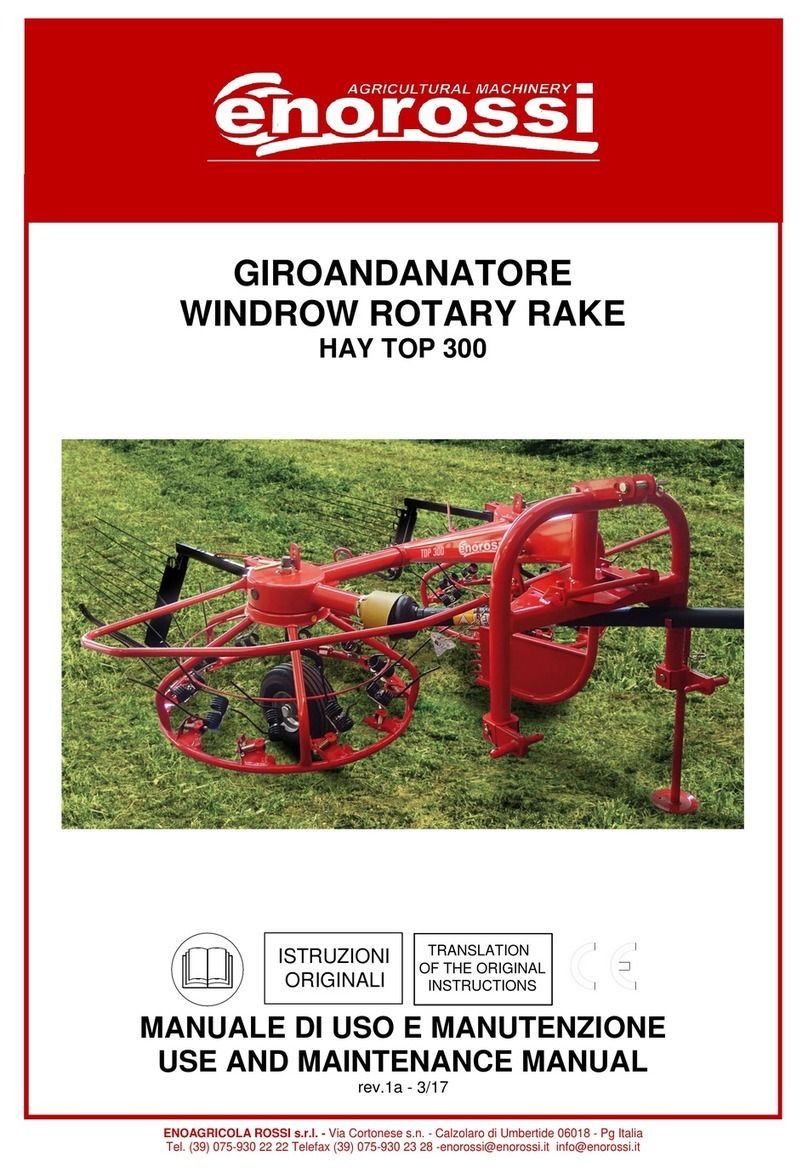

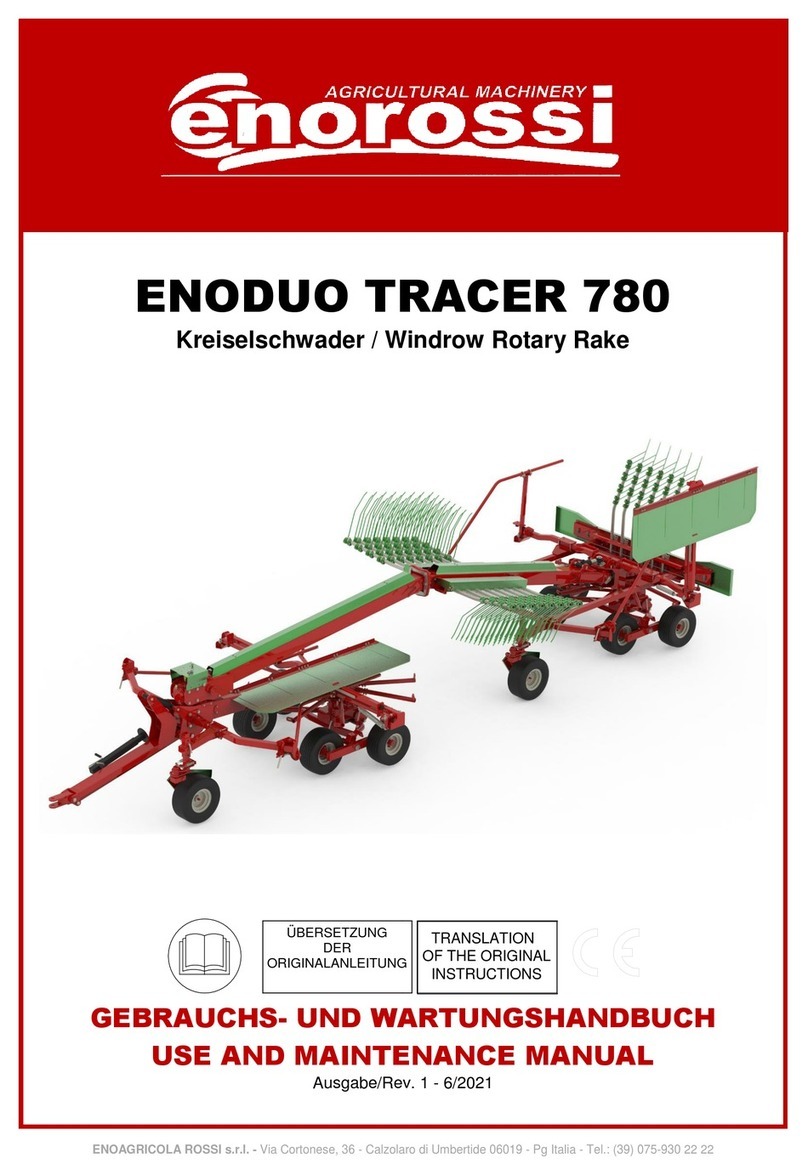

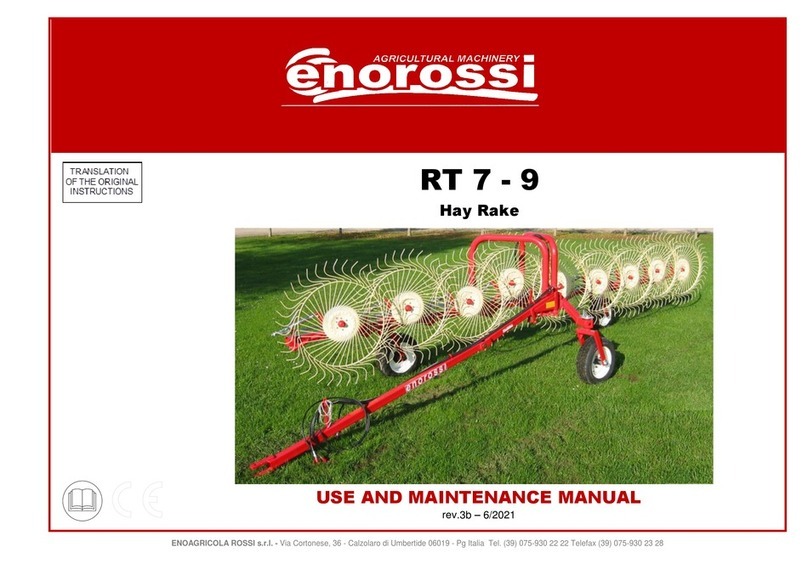

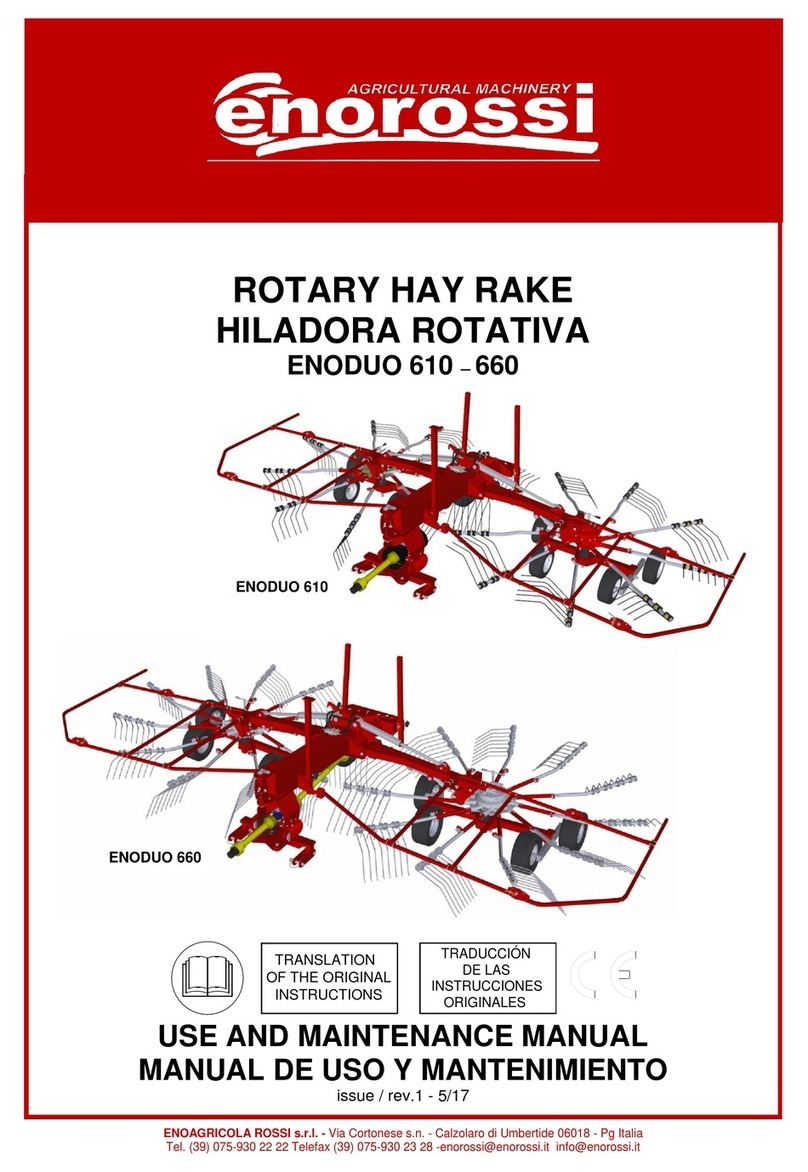

NFORMATION ON THE HAY RAKES

............................................................................................................................5

A2

I

NFORMATION ON THE MANUAL

................................................................................................................................5

A3

I

DENTIFICATION AND

EC

CERTIFICATES

....................................................................................................................6

A4

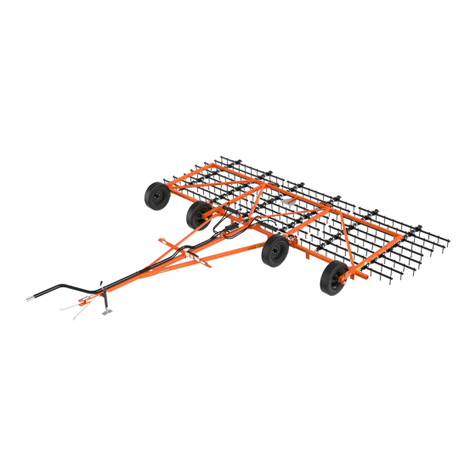

M

AIN COMPONENTS AND TECHNICAL DATA

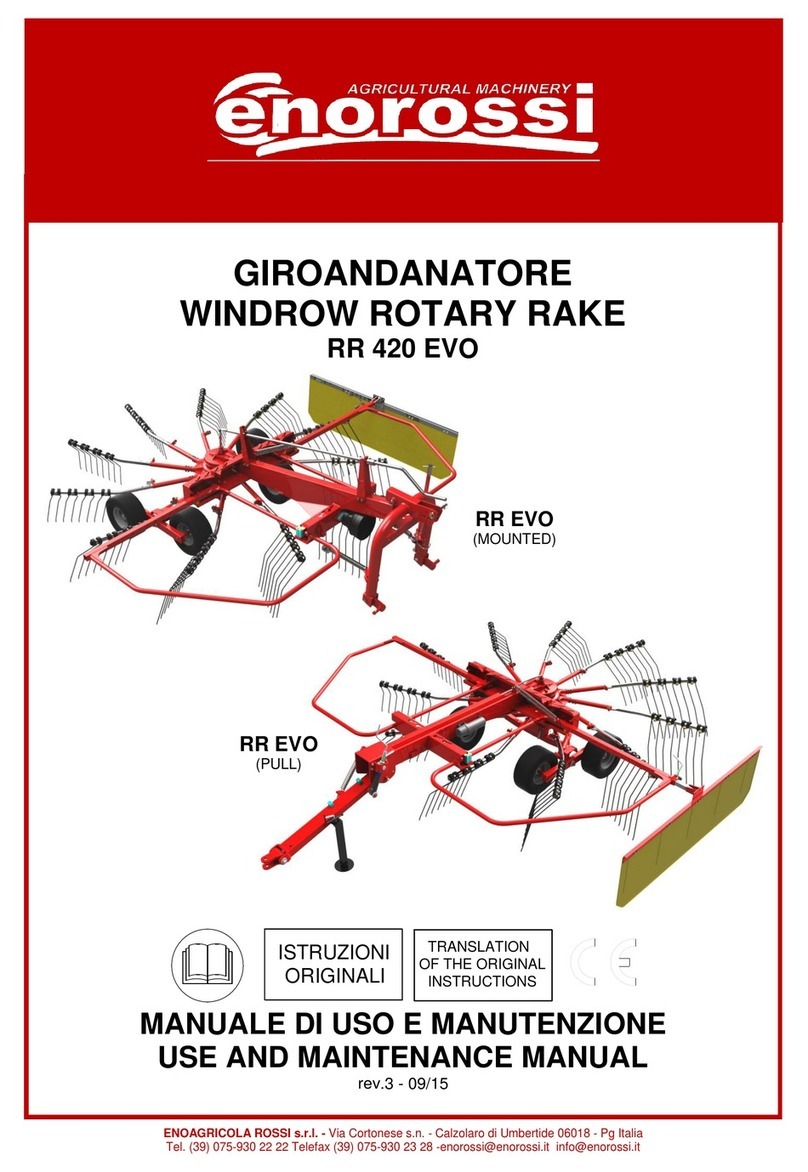

...............................................................................................................7

A5

W

ARRANTY

............................................................................................................................................................8

SAFETY............................................................................................................................................................................................................10

B1

M

AIN REGULATIONS

..............................................................................................................................................10

B2

S

AFETY REGARDING TRANSPORT

,

INSTALLATION AND DISPLACEMENT

......................................................................10

B3

U

SE AND WARNINGS

.............................................................................................................................................13

B4

I

MPROPER USE AND USE LIMITS

.............................................................................................................................15

B5

R

ESPONSIBILITIES OF THE OPERATOR

....................................................................................................................15

B6

P

ICTOGRAMS

.......................................................................................................................................................16

B7

N

OISE

..................................................................................................................................................................17

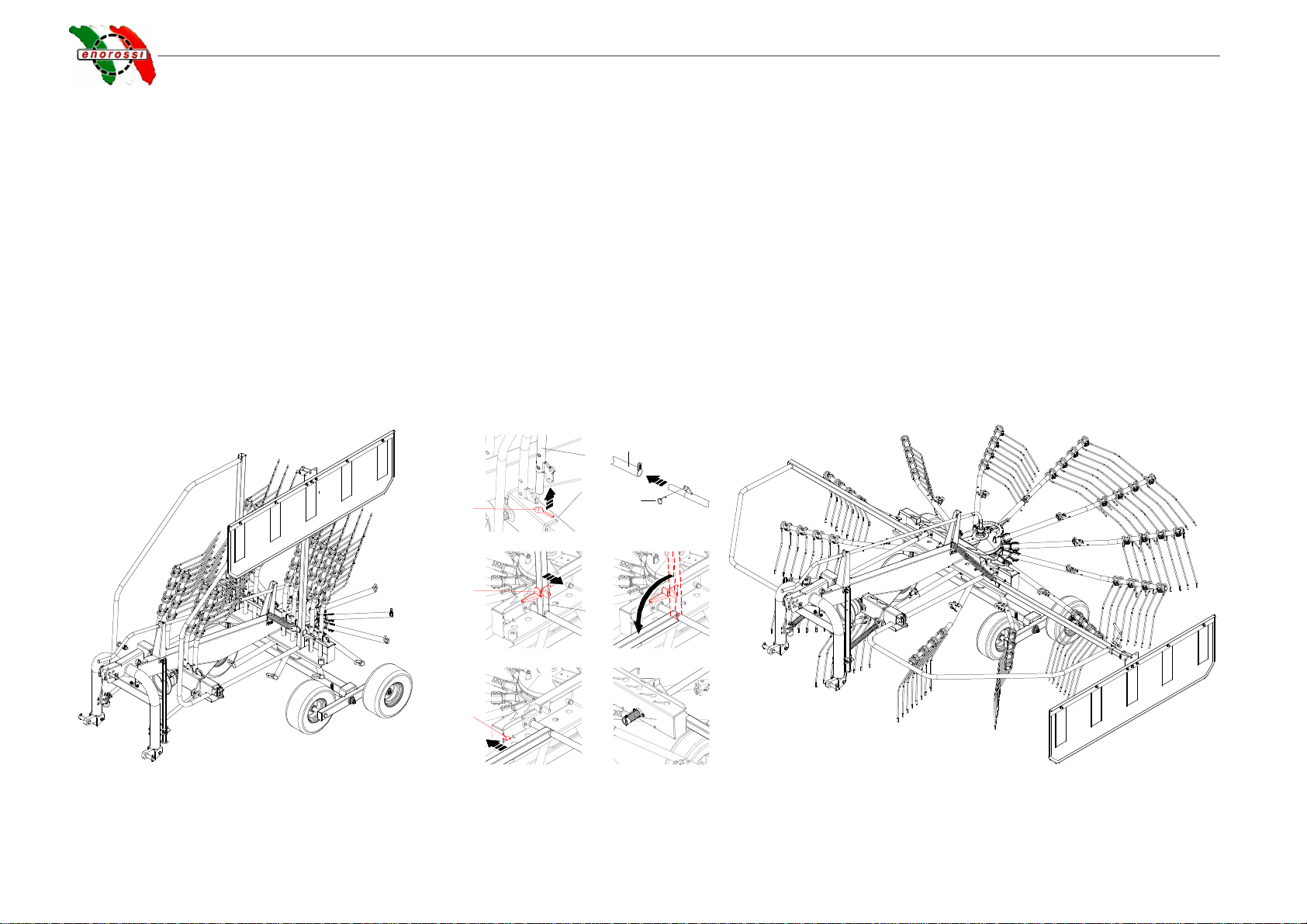

INSTALLATION................................................................................................................................................................................................18

C1

P

RELIMINARY INFORMATION

..................................................................................................................................18

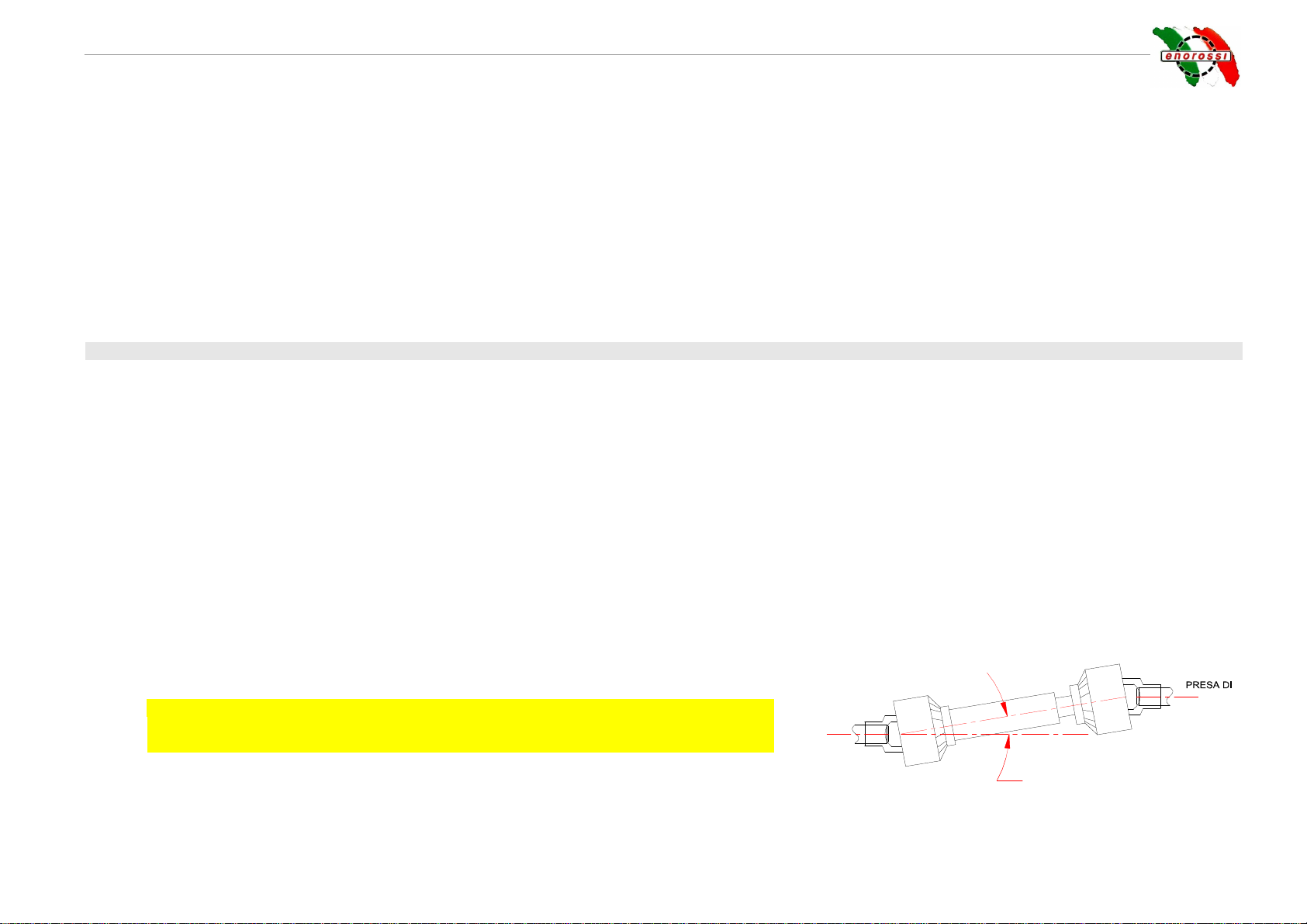

C2

I

NSTALLATION TO TRACTOR

...................................................................................................................................18

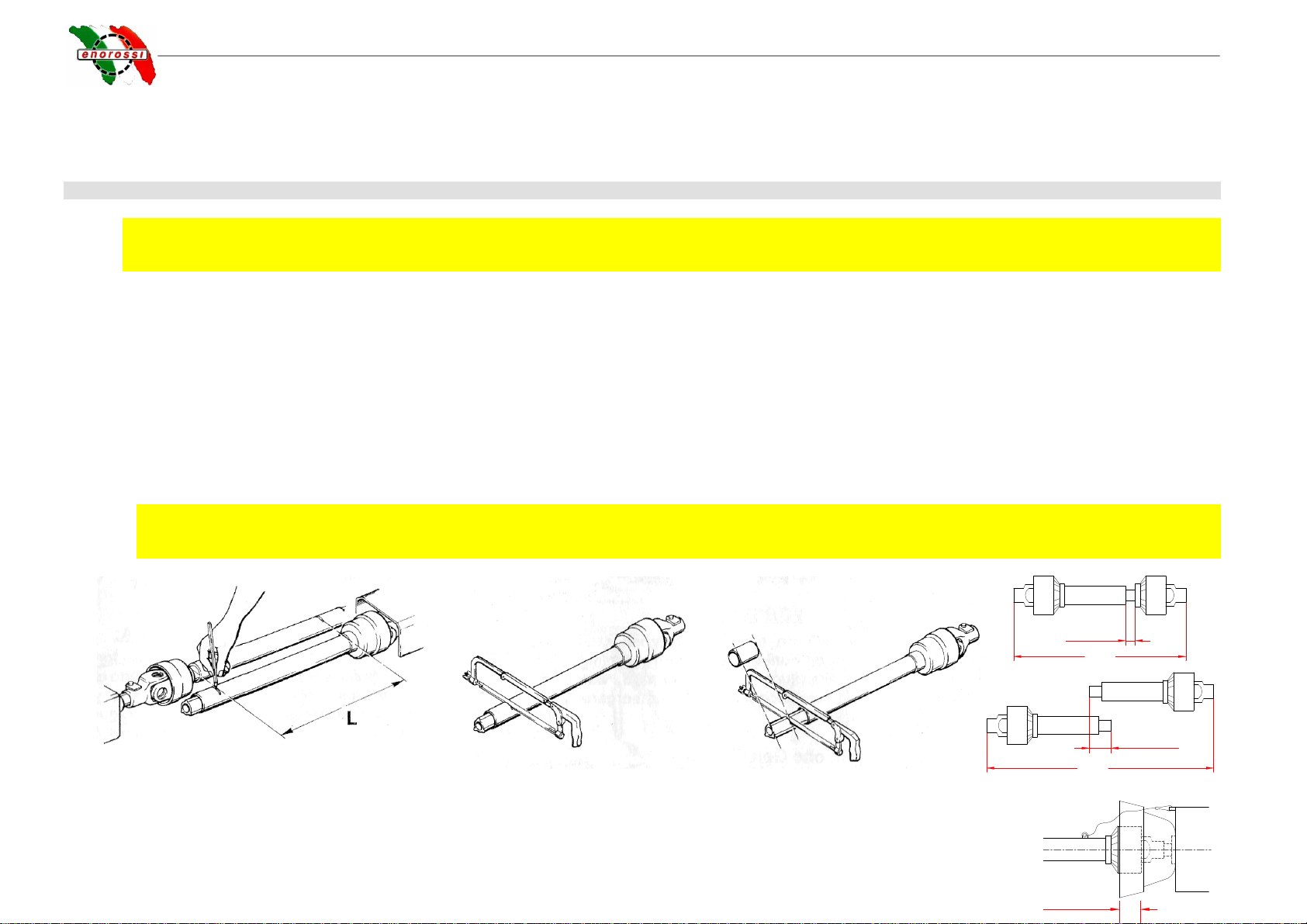

C3

I

NSTALLATION AND ADJUSTMENT OF THE CARDAN SHAFT

.........................................................................................20

C4

H

YDRAULIC CONNECTIONS

....................................................................................................................................21

C5

R

EMOVAL

.............................................................................................................................................................21

C6

S

TORING THE WINDROW ROTARY RAKE

..................................................................................................................21

OPERATION AND USE....................................................................................................................................................................................22

D1

P

RELIMINARY INFORMATION

..................................................................................................................................22

D2

O

PERATION AND

U

SE

............................................................................................................................................22

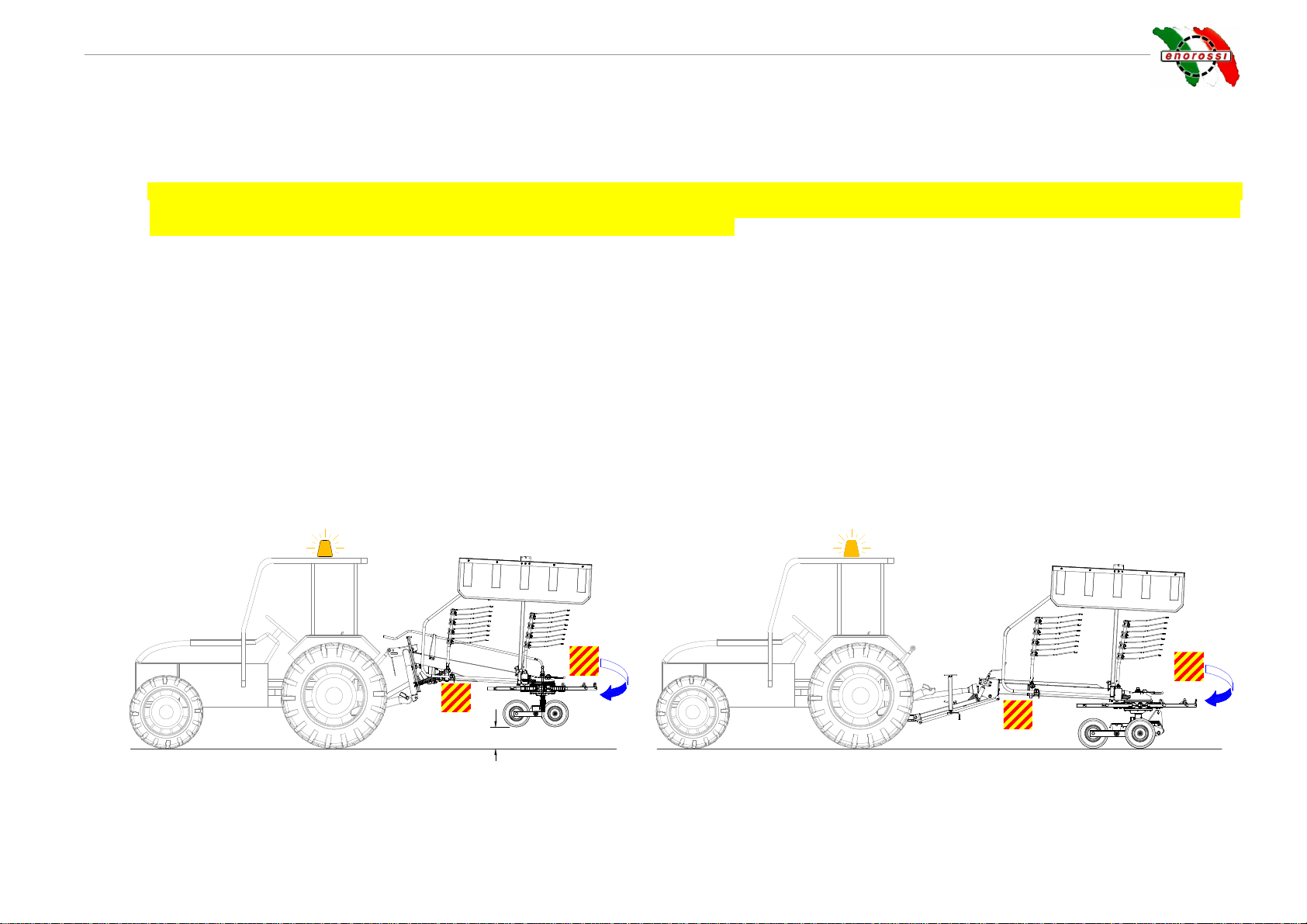

D2.1

Work configuration....................................................................................................................................................................................................................22

D2.2

Work process............................................................................................................................................................................................................................23

D2.3

Quality of the windrow...............................................................................................................................................................................................................24

D2.4

Adaptation of the parallel windrow rotary rake to the ground...................................................................................................................................................24

D2.5

Adjustment of the windrow teeth distance from the ground......................................................................................................................................................25

Adjustment of the lift speed. ..............................................................................................................................................................................................................27

D2.6

Adjustment of the side deflector distance from the ground ......................................................................................................................................................28

D2.7

Adjustment of the side deflector excursion...............................................................................................................................................................................28

D2.8

Change of direction or in reverse..............................................................................................................................................................................................28