----- CONTENTS -----

INSTRUCTION MANUAL

1. PRECAUTIONS BEFORE STARTING OPERATION ········································································1

2. SPECIFICATIONS······································································································································1

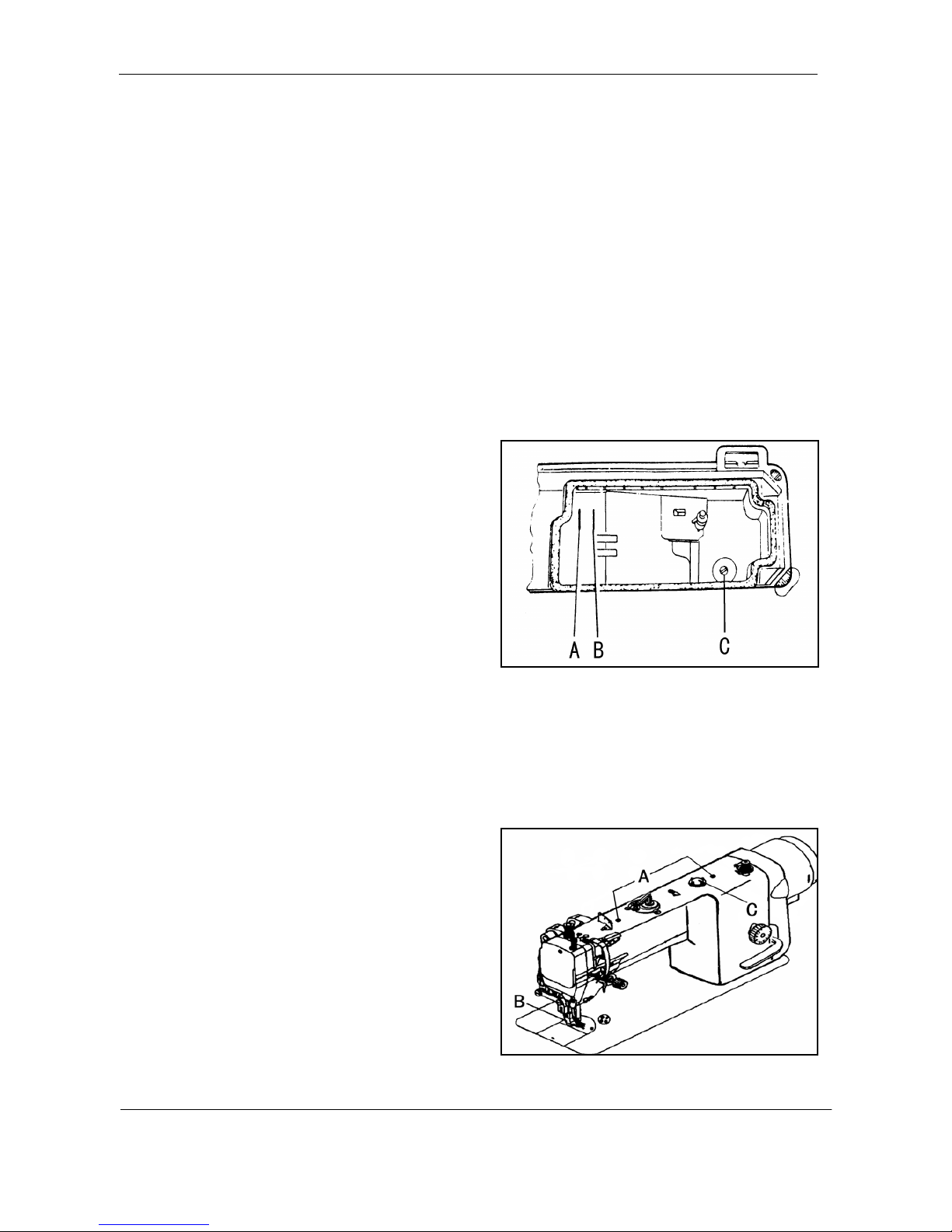

3. PREPARATION AND LUBRICATION···································································································2

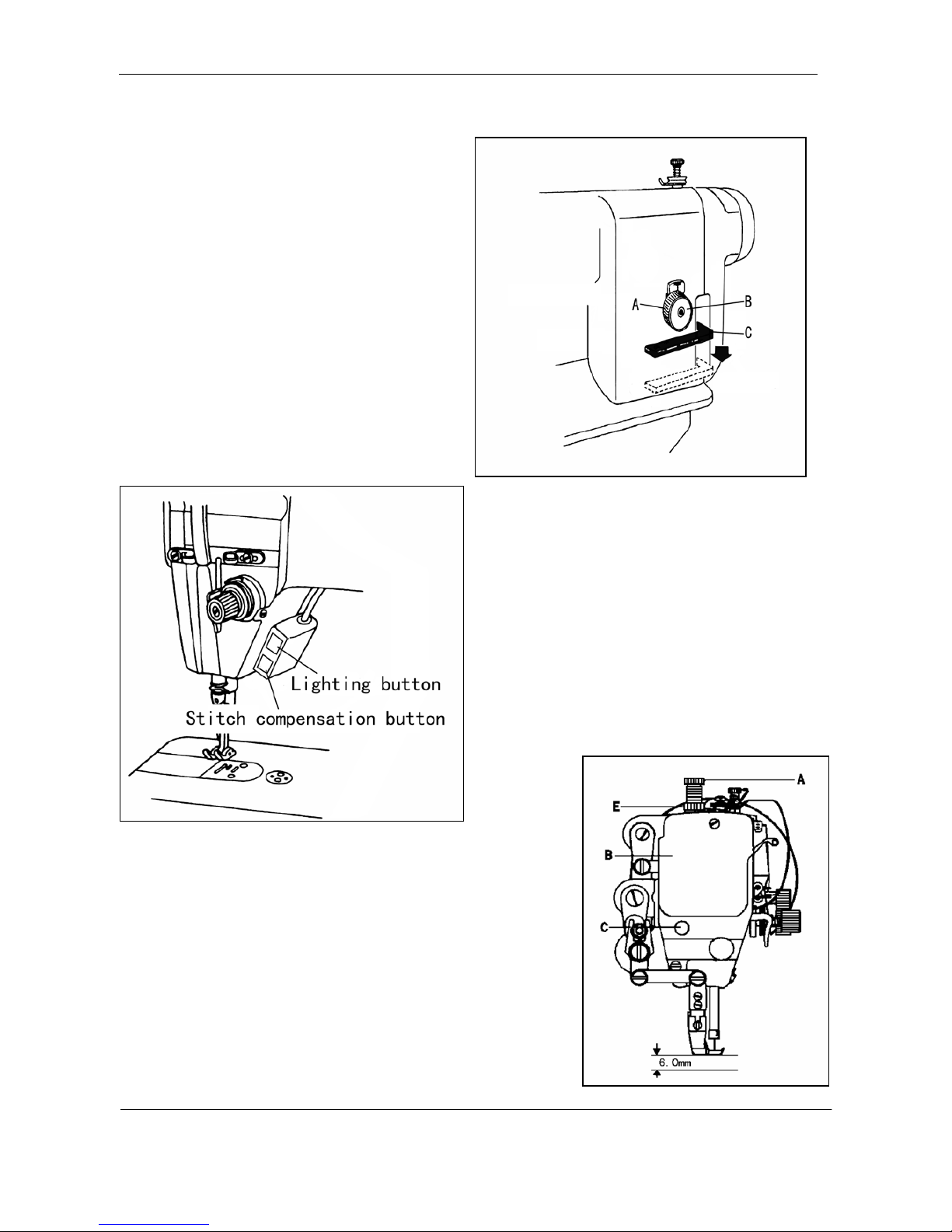

4. PREPARETION BEFORE START TO OPERATE···············································································3

5. HOW TO USE THE MACHINE···············································································································4

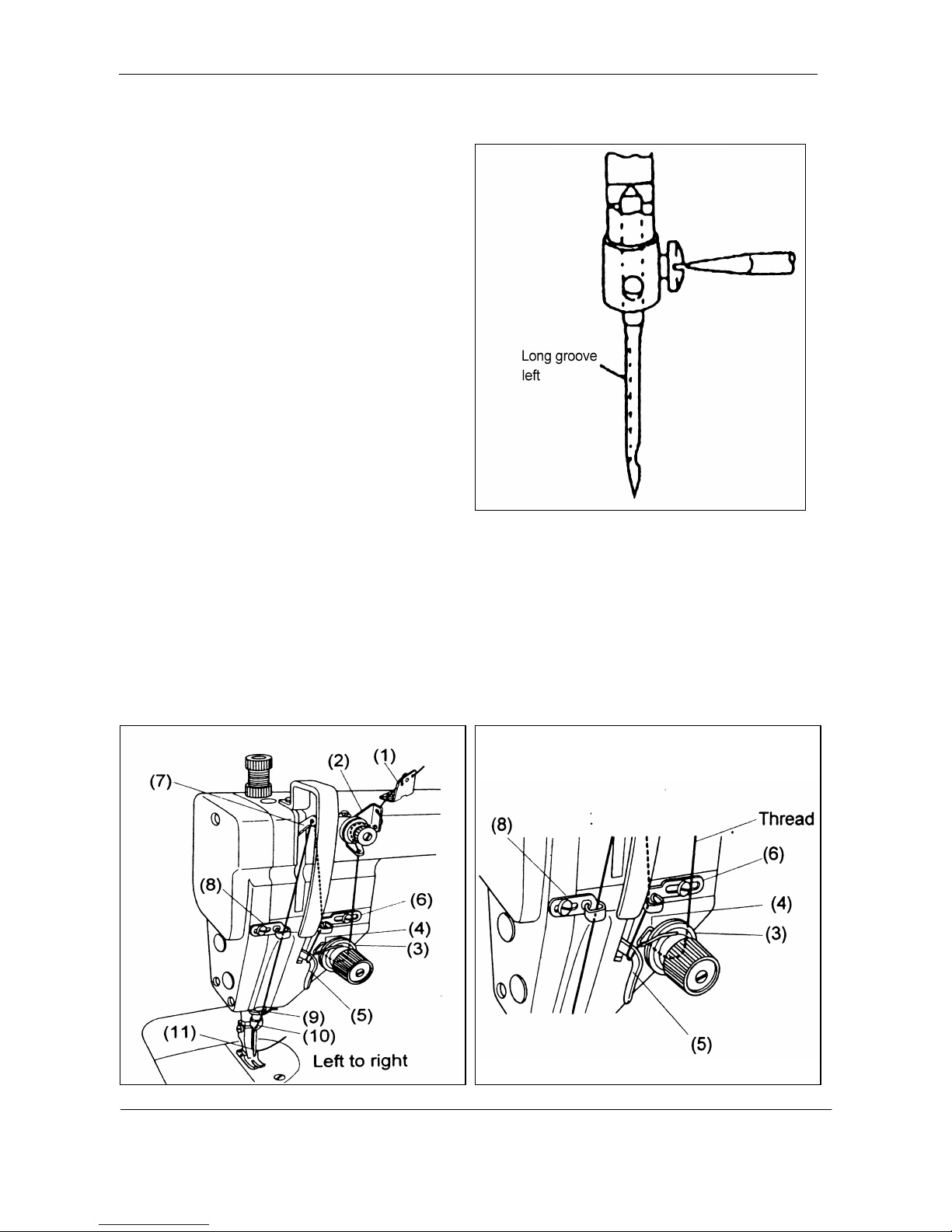

6. THREADING···············································································································································4

7. SET STITCH LENGTHAND REVERSE FEEDING···········································································5

8. POSITION PRESSER BAR·······················································································································5

9. ADJUST THE PRESSURE OF PRESSER EOOT·················································································6

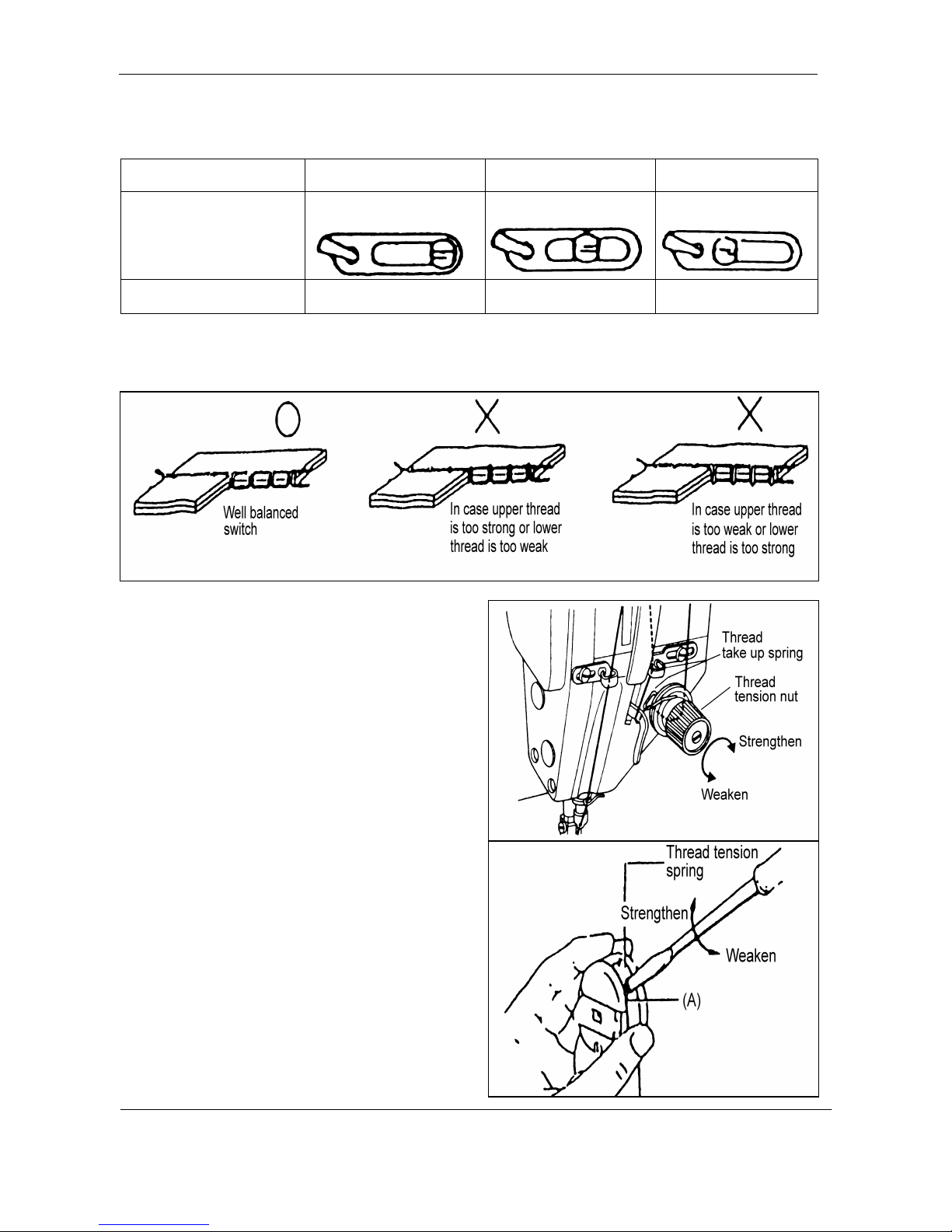

10. ADJUST THREAD TAKE-UPSPRING··································································································6

11. ADJUSTTHREAD GUIDEAND THREAD TENSION·······································································7

12. HOWTO WIND THE IOWER THREAD ON THE BOBBIN····························································8

13. TIME NEEDLE TO ROTAING HOOK ··································································································9

14. REPLACE ROTATING HOOK··············································································································10

15. ADJUST OPENINGTIME OFTHE TENSION DISCS·····································································10

16. ADJUST THE HEIGHT OF FEED DOG······························································································10

17. ADJUSTMENT OF FEED DOG INCLINATION················································································11

18. TIME FEED MOTION TO NEEDLE MOTION·················································································11

19. PERIODICALCLEANING·····················································································································12

PARTS CATALOG

A) ARM BED AND IT'S ACCESSORIES·····································································································13

B) NEEDLE BAR AND TAKE-UP LEVER & ARM SHAFT MECHANISM········································16

C) STITCH REGULATOR MECHANISM··································································································19

D) FEEDINGAND FEED LIFTING MECHANISM··················································································21

E) PRESSER FOOT MECHANISM··············································································································23

F) PRESSER LIFTING & FEEDING MECHANISM················································································25

G) OIL LUBRICATION MECHANISM········································································································28

H) MOTOR MECHANISM·····························································································································30

I) ACCESSORIES············································································································································32