4)

Testing

·•· ··• ··• ··• ··• •·• ••· ··• ••·

•••

............

···

·••

•••

·•· ·•· ·•·

...

·••

···

··• ...

···

...

··· ···

......

s

4.

Operation

•·· ··· ••·

···

·•• ··•

...

··•

...

··· ... ··· ··· ...

·•·

...

··•

··•

...

•••

...

··•

···

...

···

··•

...

···

.........

9

4.1

Se

lecting

sewing

thread

.....................................................................

9

4.2

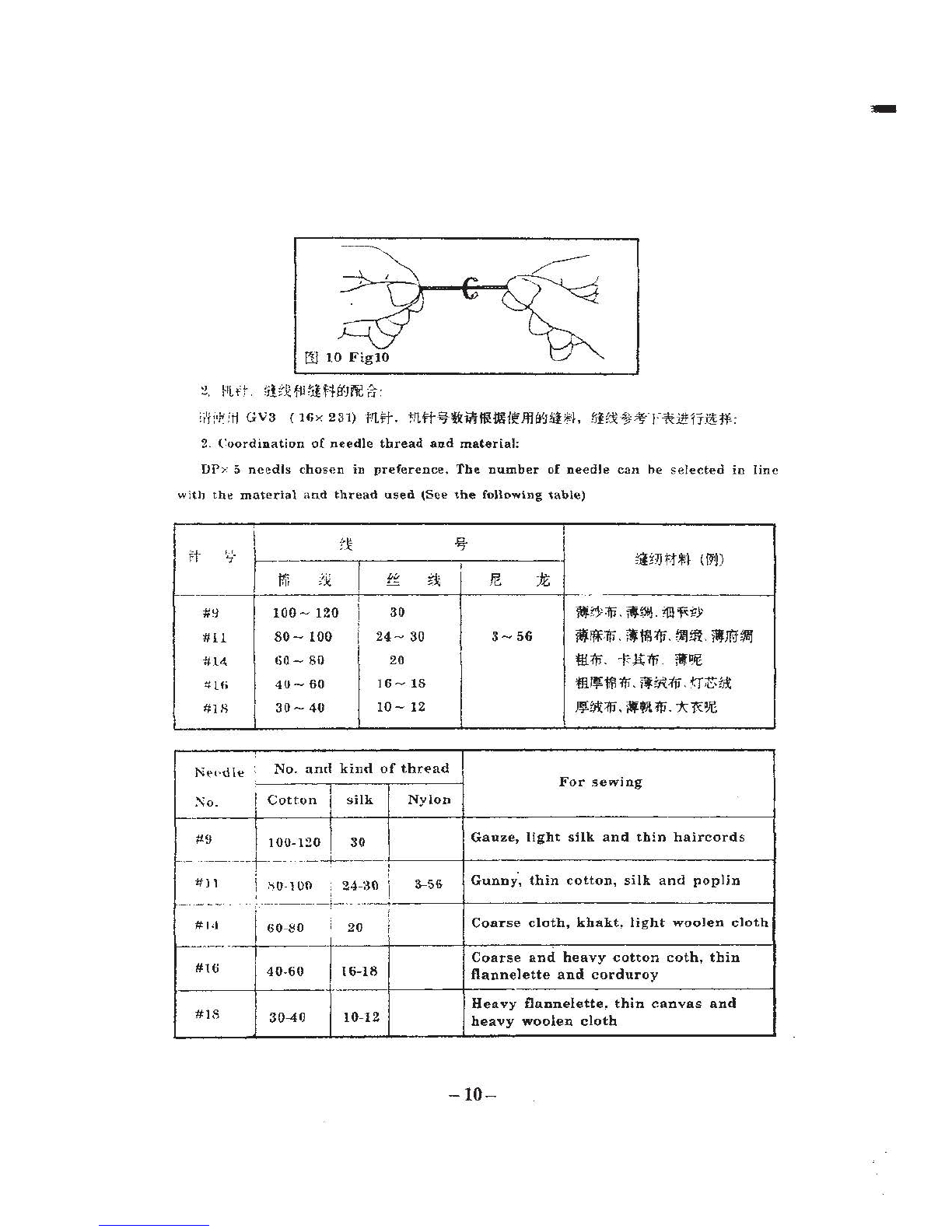

Needle

and

thre:ad

···

•··

···

··•

...

·•· ···

··

· •·• ··•

...

·

••

......

...

···

...

•·· ···

···

...

..

.

..........

10

4.3

Fitting

needle

...

......

···••

·

...

•••

...

•••

...

··•

.....

. ·•·

......

•·•···

...

·•·

......

···

............

i1

4.4

Threading

... ···

......

••·

............

··•

.........

••·

•·•

...

·•·

...

...

......

... ··· ··· ... ··· .

•.

..

.

···11

4.5

Winding

bobbin···

....

..

.

........

•·· ··• ·•• ·•· ···

··· ... ···

•·· •··

...

·

··

··•

...

······

.........

··· ...

11

4.6

Threading

bobbin

ease

..................................................................

.

.....

13

4.7

Loading

and

unloadng

bobbin····

··

.........

.

..

•••·•••••••·

...

··· .

.....

·

·····

...

••• .

..

···

·•·

14

4.8

Regulate

needle

gauge

•nd

feeding•··

......

··• •··

........................

......

............

15

4.9

Threa

d

tension

..................

···

............................................................

15

4.10

Regulating

pressure

of

pre~r

...............

·-

...

...

.......

.......

....

......

.......

..

...

17

4.11

Regulating

thread

hook

...................................................

.

..............

17

5.

Regulating

machine

...

··•

...........................

···

........................

···

... •·•

...

..

.......

17

5.1

Adjusting

looping

time

of

rotary

hoolo;

.........

·••

••

·

....

.....

•

·•

... ···

...............

--·18

5.2

Regulating

l

ength

of

feed

dogs

.......

...

....................

...........

.

..................

19

6.

Common

troubles

and

methods

of

treatment

............

··•

............

·••

... ...

···

......

...

---19

Parts Book

1.

Accessories

of

machine

head

........................................

.

......................

22

2.

Components

of

case

...............................................................

•··

···

......

23

3.

Upper

shaft,

needle

bar

components

.........

··· ···

·••

............

···

.....................

25

4.

Presser

bar

components

......................................................

.

...........

··· 28

5.

Components

oJ

lower

shaft

and

rotary

hoolc.

:"

...

••·

..................

••·

.........

30

6.

Feedin9.

lifting

belt

components

.....

.

.....................

·.••

... ... ... ...

...

... ...

...

...

32

7.

lubricaton

components

..

.

....

..

•·••••

...

·••

.........

·-

...........................

··•

......

35

8.

011

re

servo

ir

&

!!nee

lifter

componet~ts

·-

..................

·••

..................

···

••·

... 38

9.

components

of

thread

winder,

double

1hread

bobbin

.................................

40

10.

Co

mponents

of

table

plate,

electrical

equipment

...

......................

..............

43

11.

Components

or

m

aclline

stand

........................

•••

.....

. •·•

·•· ··•

...

... ...

...

...

...

45

-3-

From the library of: Superior Sewing Machine & Supply LLC