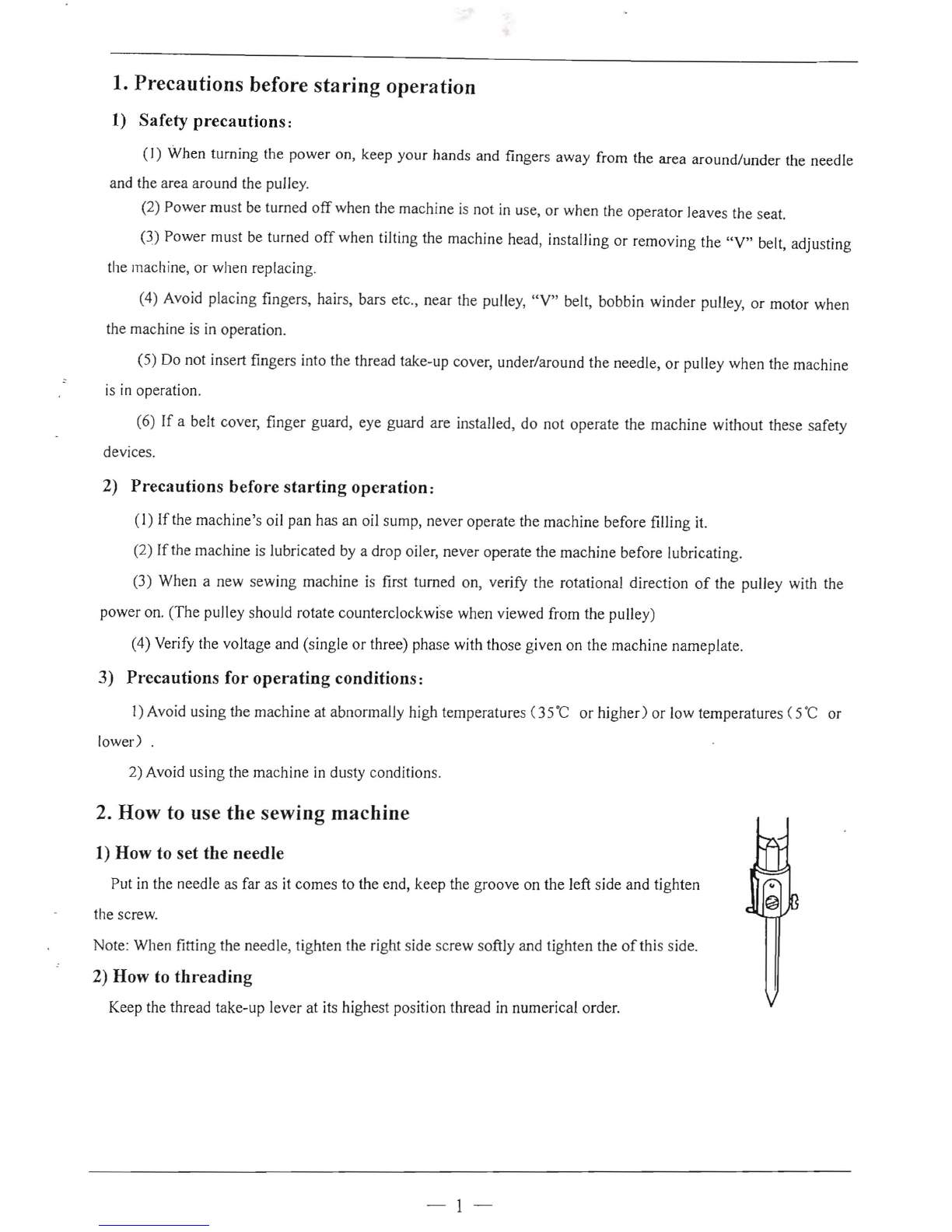

(4) When the small looper is in its left most position, the position

of

the slot bottom in the small looper

must come out I to 2mm from the side face

of

the hook needle as illustrated in

Flg.Ll

.

If

this projection is

excessive, the chain-off thread will be difficult to come out. To adjust the

position

of

the small looper, loosen the setscrew in the small looper block as

illustrated in

Fig.n.

Fig

,12

Fig.11

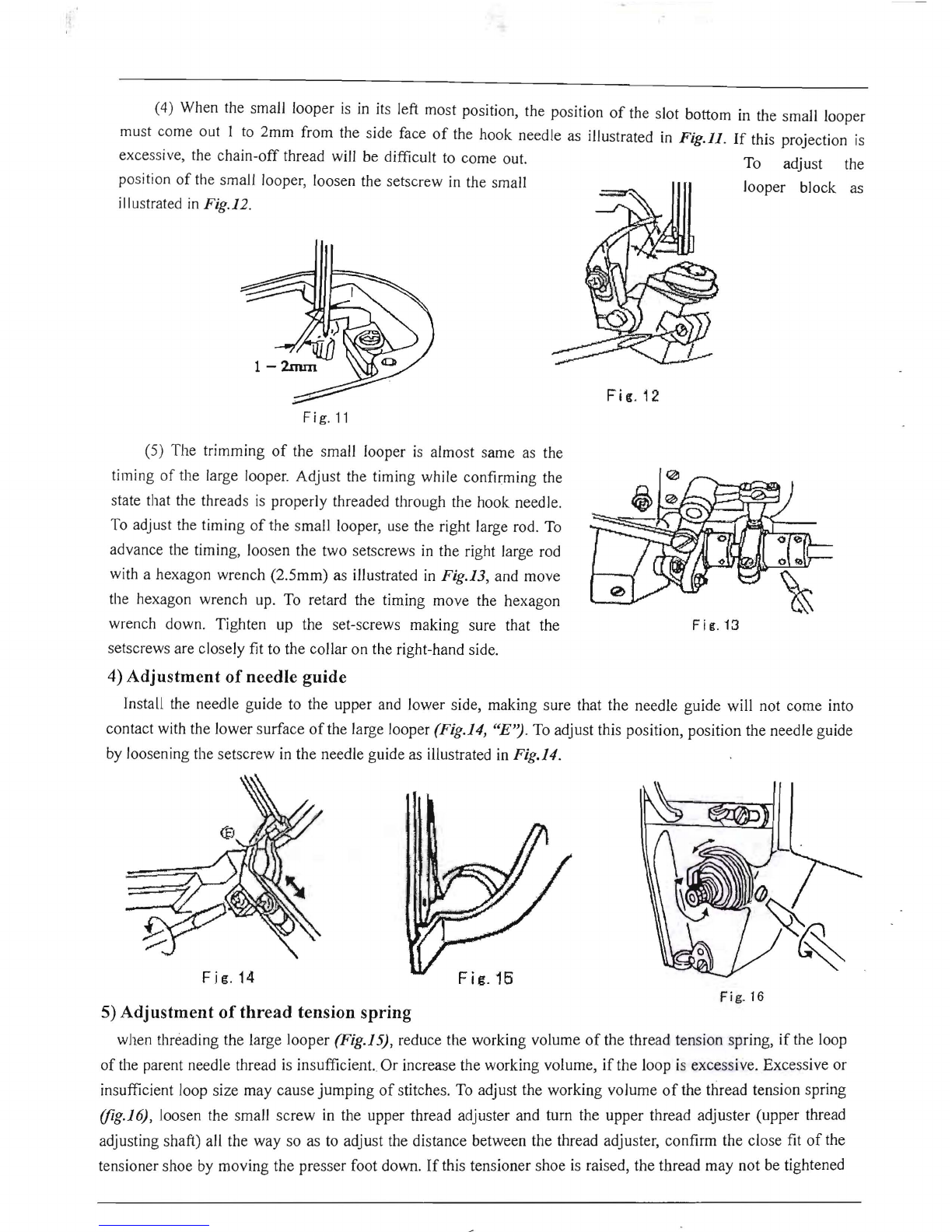

(5) The trimming

of

the small looper is almost same as the

timing

of

the large looper. Adjust the timing while confirming the

state that the threads is properly threaded through the hook needle.

To adjust the timing

of

the small looper, use the right large rod. To

advance the timing, loosen the two setscrews in the right large rod

with a hexagon wrench (2.5mm) as illustrated in Fig.13, and move

the hexagon wrench up. To retard the timing move the hexagon

wrench down . Tighten up the set-screws making sure that the

setscrews are closely fit to the collar on the right-hand side.

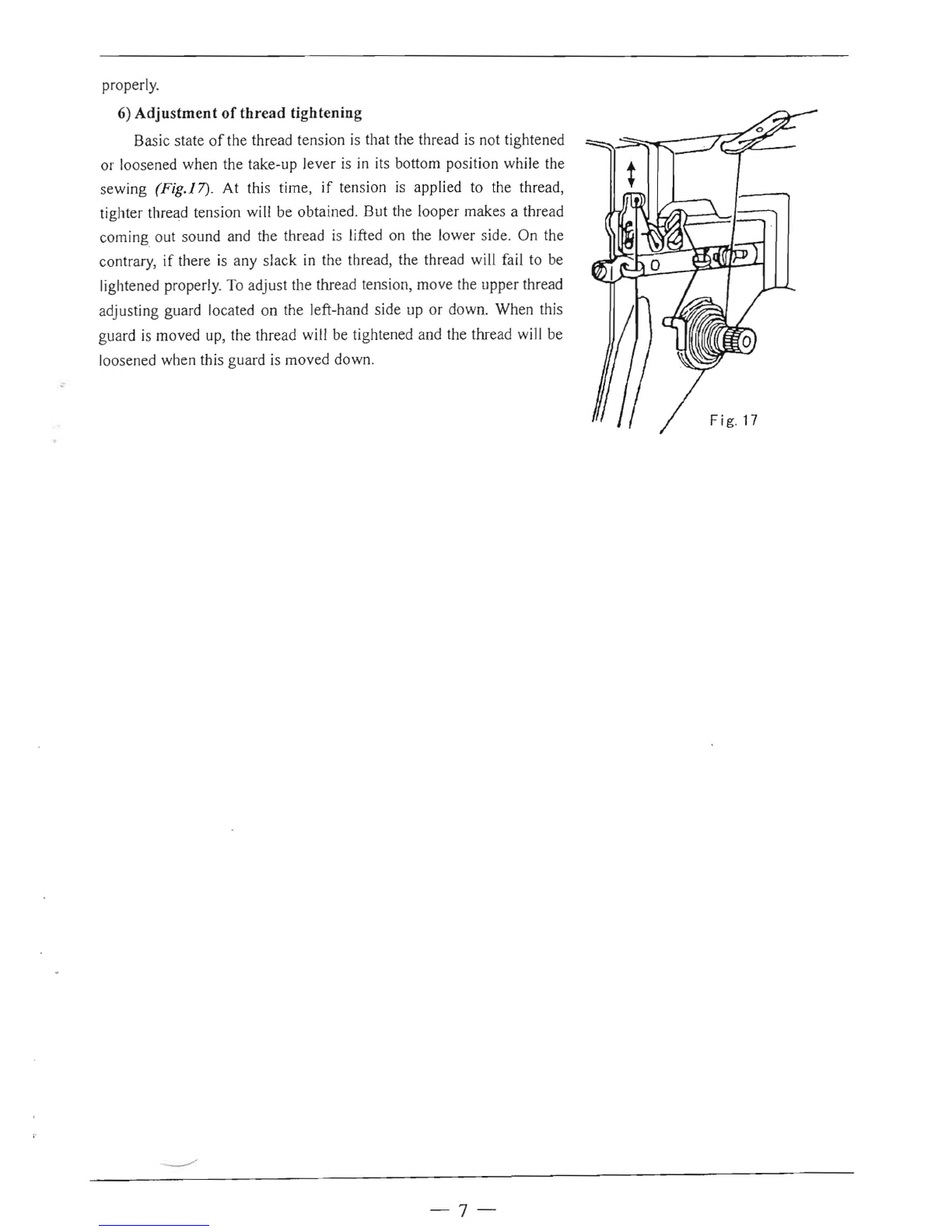

4)

Adjustment

of

needle guide

Install the needle guide to the upper and lower side, making sure that the needle guide will not come into

contact with the lower surface

of

the large looper (Fig.14,

"E")

. To adjust this position, position the needle guide

by loosening the setscrew in the needle guide as illustrated in Fig.14.

F j it. 13

I~l

Fig

.16

F j g. 14

Fig.16

5)

Adjustment

of

thread

tension

spring

when threading the large looper (Fig.IS}, reduce the working volume

of

the thread tension spring, if the loop

of

the parent needle thread is insufficient. Or increase the working volume, if the loop is excessive. Excessive or

insufficient loop size may cause

jumpin

g

of

stitches. To adjust the working v

olume

of

the thread tension spring

(fig.Iti), loosen the small screw in the upper thread adjuster and turn the upper thread adjuster (upper thread

adjusting shaft) all the

way

so as to adjust the distance between the thread adju

ster

, confirm the close fit

of

the

tensioner shoe by moving the presser foot down.

If

this tensioner shoe is raised, the thread may not be tightened