Base plate :476×178mm

Working space to the right of the needle :265×128mm

Needle throw and sewing speed

4.5mm 2800 stitches per minute

6.0mm 2800 stitches per minute

8.0mm 2600 stitches per minute

12.0mm 2200 stitches per minute

Machines with cam- device for utility and decorative stitches, stitches per minute for

decorative -utility stitch

6.0mm 2,300 2,800

8.0mm 2,100 2,800

12.0mm 1,800 2,600

Machines with other extra attachments such as:

Puller as basic model

displacement left-centre-right

Stitch length forward and reverse: 5.5mm

Max. presser foot lift: 8.5mm

Needle system: 12.0mm needle throw =134R,

No.70-120

Shuttle system: continuous double rotation,

transverse position

Thread tension: double thread tension

Raising presser foot: knee lever with extra upper holding

position.

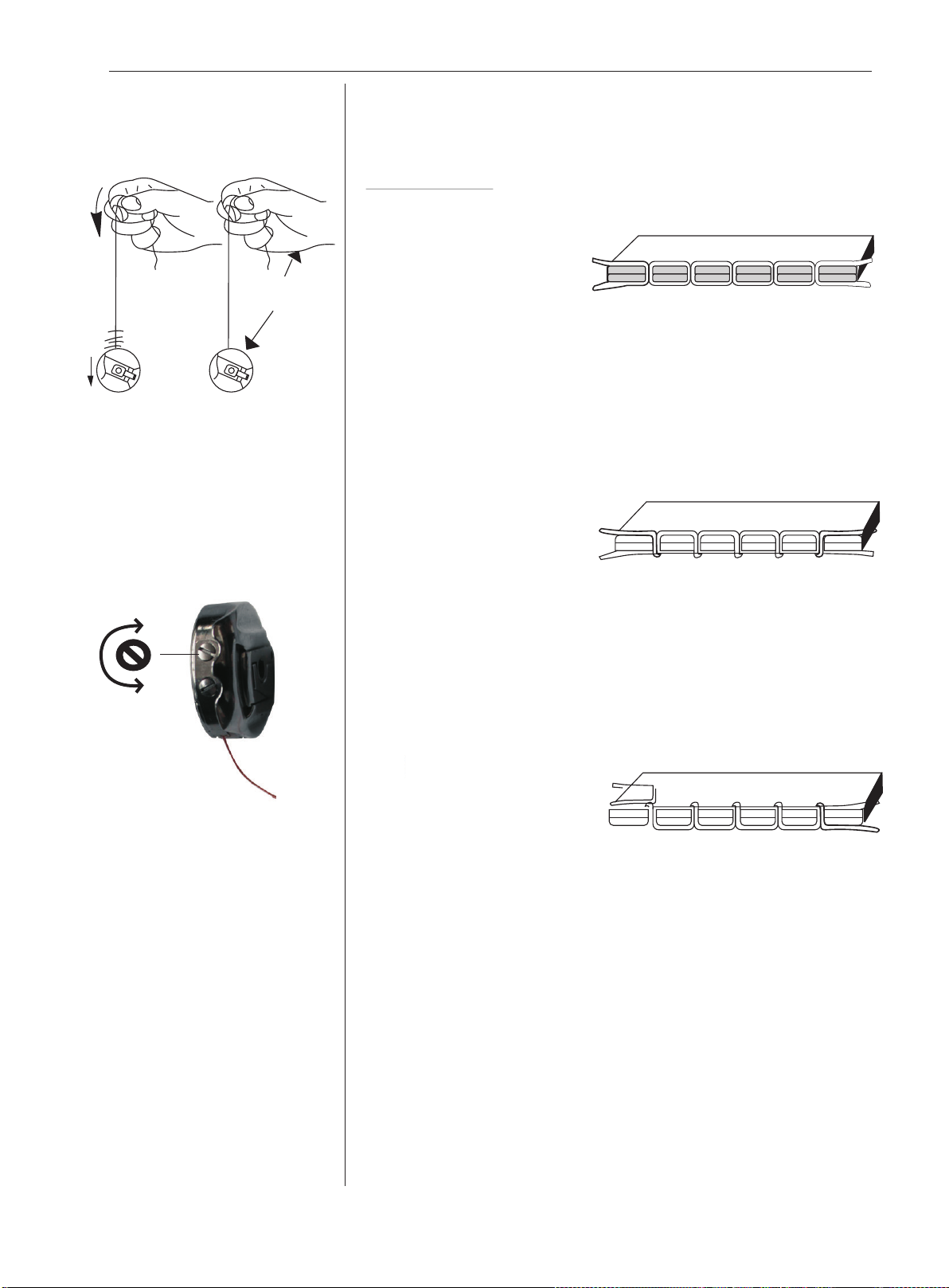

Stitch

Important points to note:

· Oil machine thoroughly before

using for first time.

●When doing so, strictly observe

instructions.

●Check that the mains voltage

corresponds to the voltage given on

the motor ,if the voltages are not the

same, do not on any account

operate the machine.

● Check the guards for finger, take-

up lever and belt are all present.

● When the machine is running the hand

wheel should turn anti-clockwise , if it

dose not reverse the terminals on the

motor.

●Use only recommended needle

system.

● Clean machine regularly.

● Do not start machine until the fabric

is in position under the presser foot.

● When removing fabric always bring

thread take-up lever at highest

position.

● For the first 2 weeks, run machine

at only 3/4 of its maximum speed.

●The presser foot can be raised either

with the hand lever or with the knee

lever.

●When making adjustments to the

machine and when sewing is finished

the machine and when sewing is

finished the motor should be switched

off or disconnected at the mains.

When using a clutch motor , wait

until it has stopped.

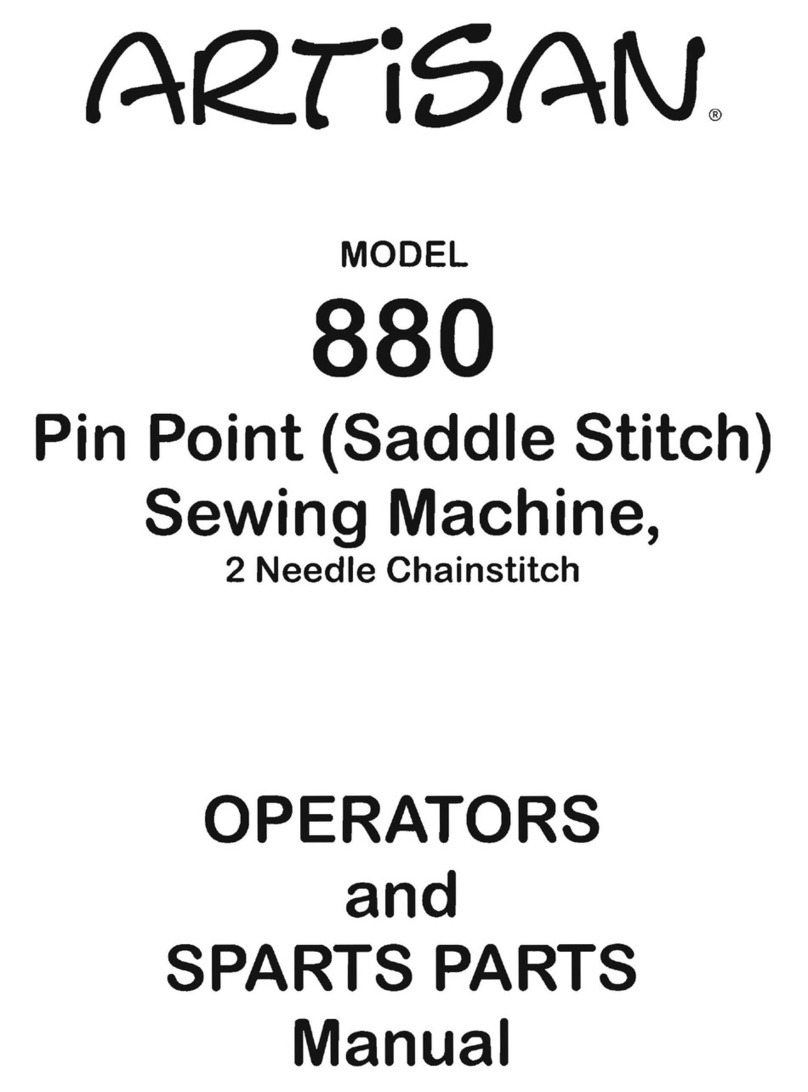

1 Base plate

2 Base plate slide

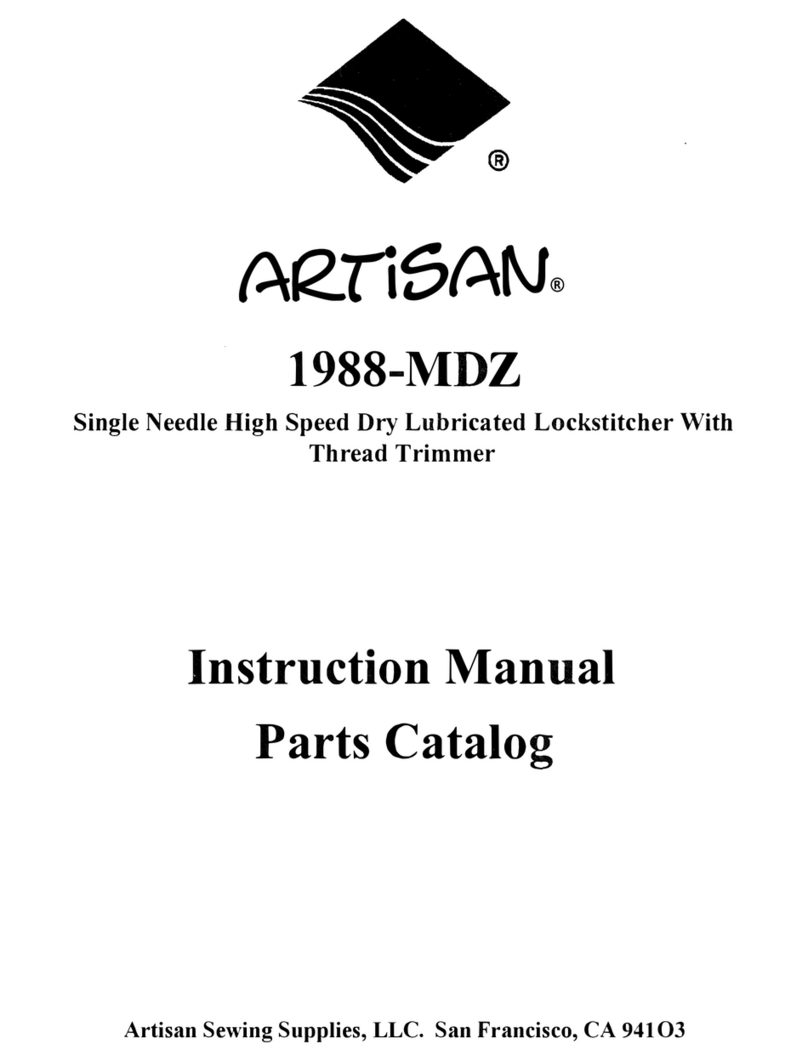

3 Needle plate

4 Presser foot screw and thread cutter

5 Needle holder

6 Thread regulator

7 Double thread tension

8 Front cover

9 Thread take-up lever

10 Regulating screw for presser foot

pressure

11 Thread guide pin Embroidery

machine: thread draw-off

12 Am cover

13 Lever for needle position

14 Lever for stitch width

15 Stops for limited stitch width

16 Belt guard

17 Hand wheel

18 Hub for synchroniser

19 Lever for stitch length

20 knob for fine setting of stitch length for

sewing satin stitch

21 Buttonhole density stop

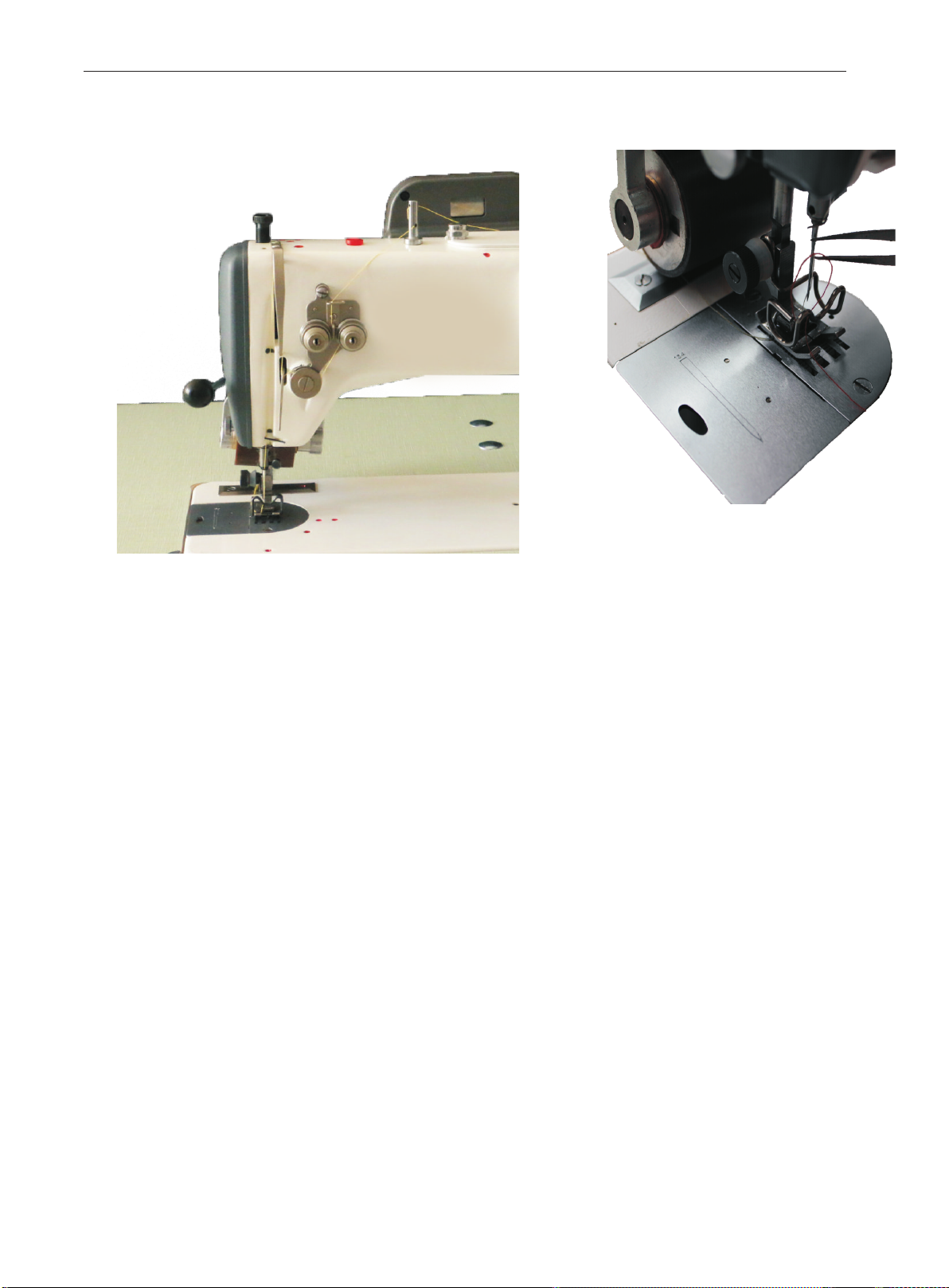

22 Bobbin winder

23 Thred stand

Technical lnformation List of parts

476

63

128

265

1

23

4

5

6

7

8

9

10 11 12

13

14

17

16

15

19

21

20

18

22

23

23