[AP4470]

200200020-E-01 2020/3

- 2 -

4. Table of Contents

1. General Description ............................................................................................................................ 1

2. Features .............................................................................................................................................. 1

3. Applications......................................................................................................................................... 1

4. Table of Contents ................................................................................................................................ 2

5. Block Diagram..................................................................................................................................... 3

5.1. Block Diagram.............................................................................................................................. 3

5.2. Block Function ............................................................................................................................. 3

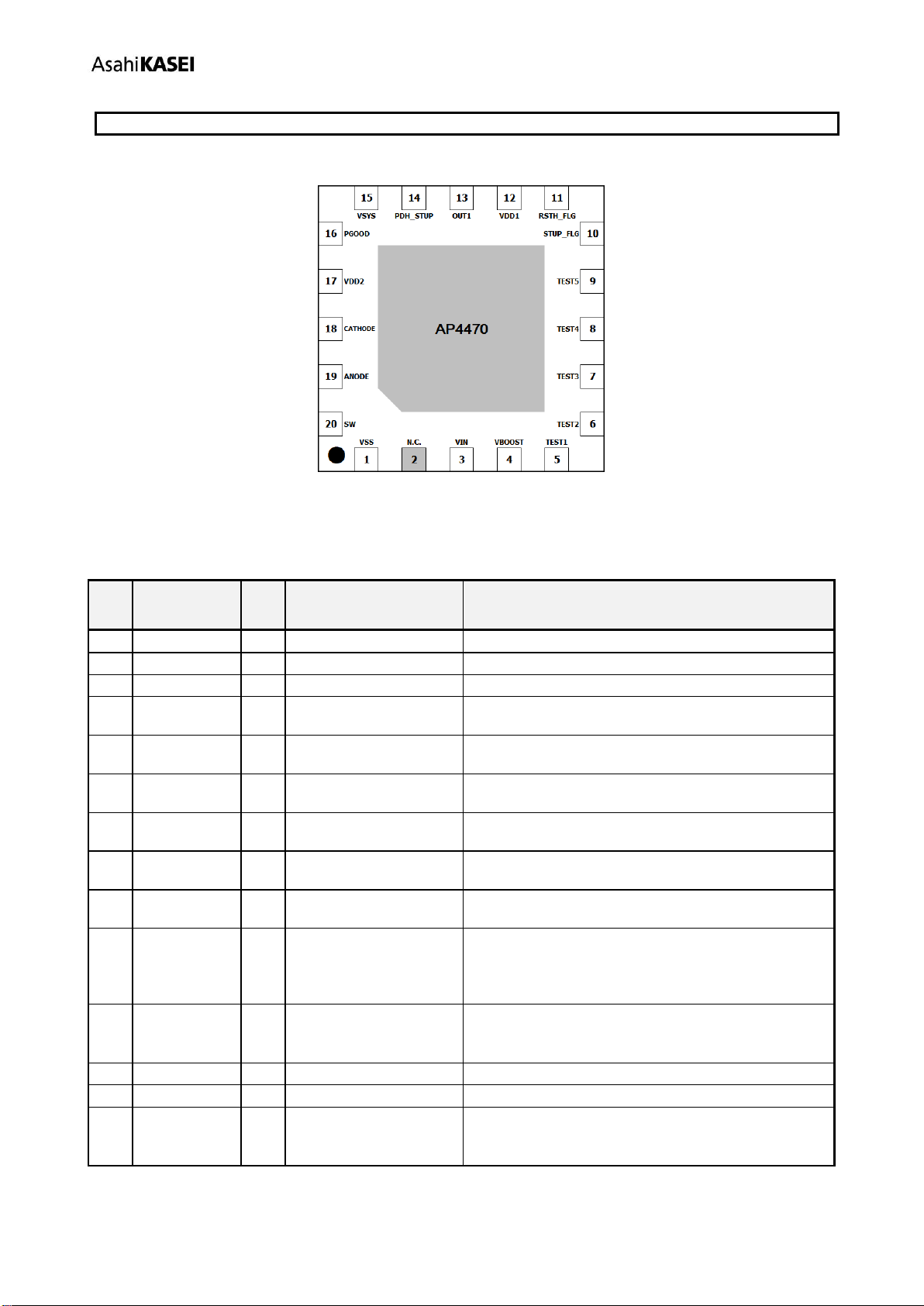

6. Pin Configuration and Function .......................................................................................................... 4

6.1. Pin Configuration ......................................................................................................................... 4

6.2. Pin Function ................................................................................................................................. 4

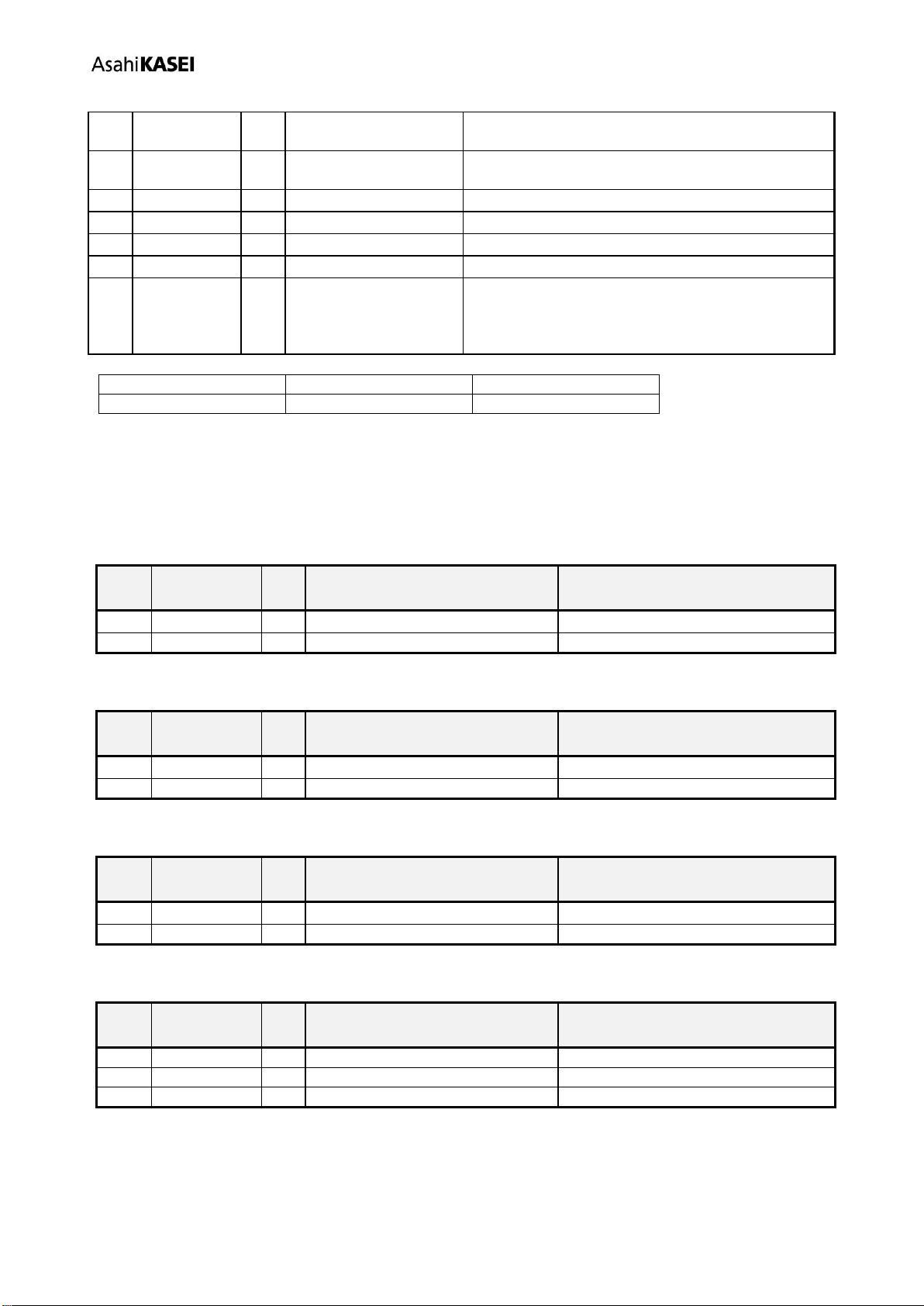

6.3. The connection of unused pins.................................................................................................... 5

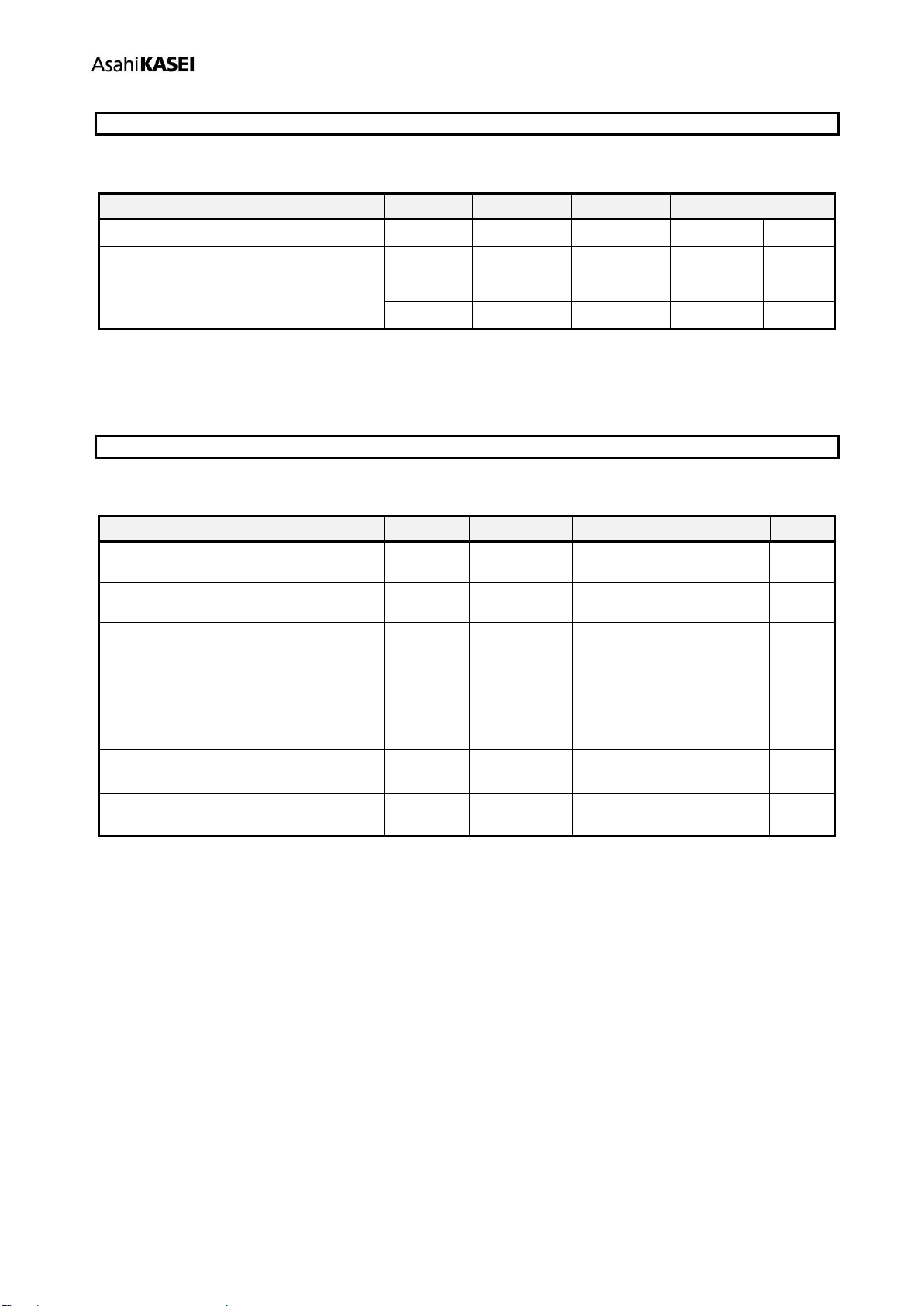

7. Absolute Maximum Ratings ................................................................................................................ 6

8. Recommended Operating Conditions................................................................................................. 7

9. Digital DC Characteristics................................................................................................................... 7

10. Electrical Characteristics ................................................................................................................. 8

11. Description....................................................................................................................................... 9

11.1. Hysteresis comparator 1 (COMP1).......................................................................................... 9

11.1.1 When VDD1 voltage is increasing (Up phase) ........................................................................ 9

11.1.2 When VDD1 voltage is decreasing (Down phase) .................................................................. 9

11.2. Hysteresis comparator 2 (COMP2).......................................................................................... 9

11.3. Startup to DC/DC operation ................................................................................................... 10

11.3.1 Cold Startup ........................................................................................................................... 13

11.3.2 DC/DC .................................................................................................................................... 13

11.3.2.1 When (ISTRG > (IOUT + IVDD1 + IVDD2)).................................................................................... 13

11.3.2.2 When (ISTRG < (IOUT + IVDD1 + IVDD2)).................................................................................... 13

11.4. Power Good ........................................................................................................................... 14

11.5. Startup FLG............................................................................................................................ 15

12. Test Circuits................................................................................................................................... 16

12.1. External Circuit Example........................................................................................................ 16

12.2. PCB Guidline.......................................................................................................................... 17

13. Typical Characteristics .................................................................................................................. 18

13.1. Cold Startup ........................................................................................................................... 18

13.2. Switching Frequency.............................................................................................................. 18

13.3. Low side ON pulse width ....................................................................................................... 19

13.4. COMP1................................................................................................................................... 19

13.5. COMP2................................................................................................................................... 20

13.6. Current consumption.............................................................................................................. 20

13.7. Load curve.............................................................................................................................. 22

14. Recommended External Circuit .................................................................................................... 23

14.1. External Circuit Example........................................................................................................ 23

14.2. Reference PCB ...................................................................................................................... 24

15. Packages....................................................................................................................................... 25

15.1. Outline Dimensions................................................................................................................ 25

15.2. Marking................................................................................................................................... 25

16. Ordering Guide.............................................................................................................................. 26

17. Revision History............................................................................................................................. 26

IMPORTANT NOTICE.............................................................................................................................. 27