2

-Allow sufcient space for maintenance and inspection.

-Keep the valve out of direct sunlight, water and dust. Use cover to shield

the valve. (The valve will not operate properly.)

-Install the piping in such a manner that it will not be exposed to direct

sunlight. (The body may otherwise get discolored or the screen may get

distorted, resulting in failure to function.)

-Perform periodic maintenance. (Leakage may develop due to temperature

changes or periods of prolonged storage, rest, or operation.)

-When installing pipes and valves, ensure that they are not subjected to

tension, compression, bending, impact, or other excessive stress.

-When installing, disassembling, or reassembling the piping, x the End

Connector.

-Fasten the Union Nut while avoiding the parallelism and axial misalignment

of the ange surface.

-When connecting an ASAHI AV Valve to metal piping, take care not to let

pipe stress to ASAHI AV Valve.

-The Y-SEDIMENT STRAINER is so structured as to be vulnerable to

repeated stresses due to internal pressure changes in the corner. Damage

may therefore occur in a line subject to pulsation. (including air hammering

and water hammering)

-Use the valve at a level less than the permissible ow speed.

(The screen may otherwise get distorted or damaged.)(Scheme 1)

-Periodically clean the screen in accordance with use.

-Before a water test, be sure that the Union Nut is tightly fastened.

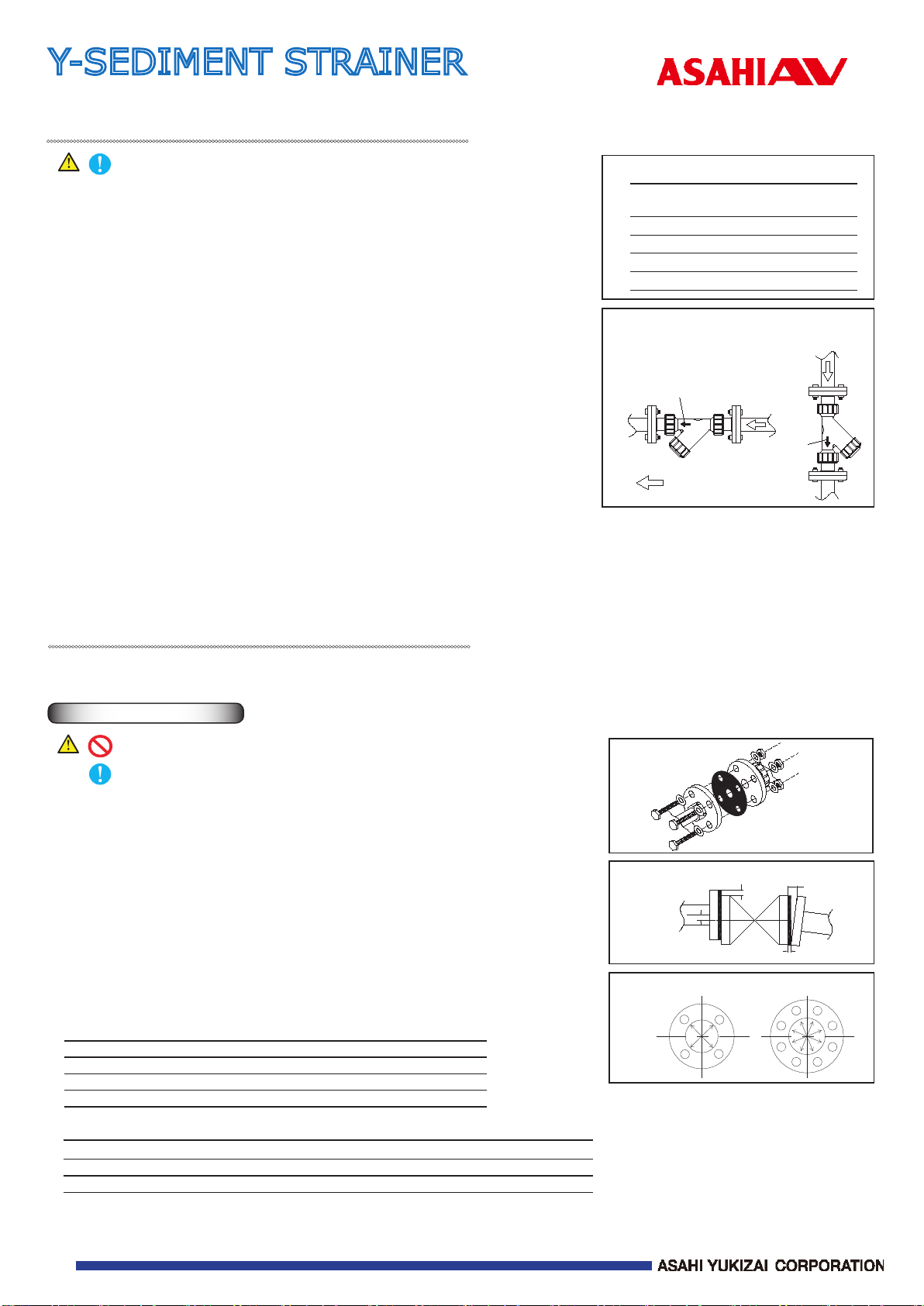

-Plumb in the strainer considering the uid direction (the arrow is shown on

the body) so that the screen points downward.(Fig.1)

General Operating Instructions

Flanged End

Installation Procedure

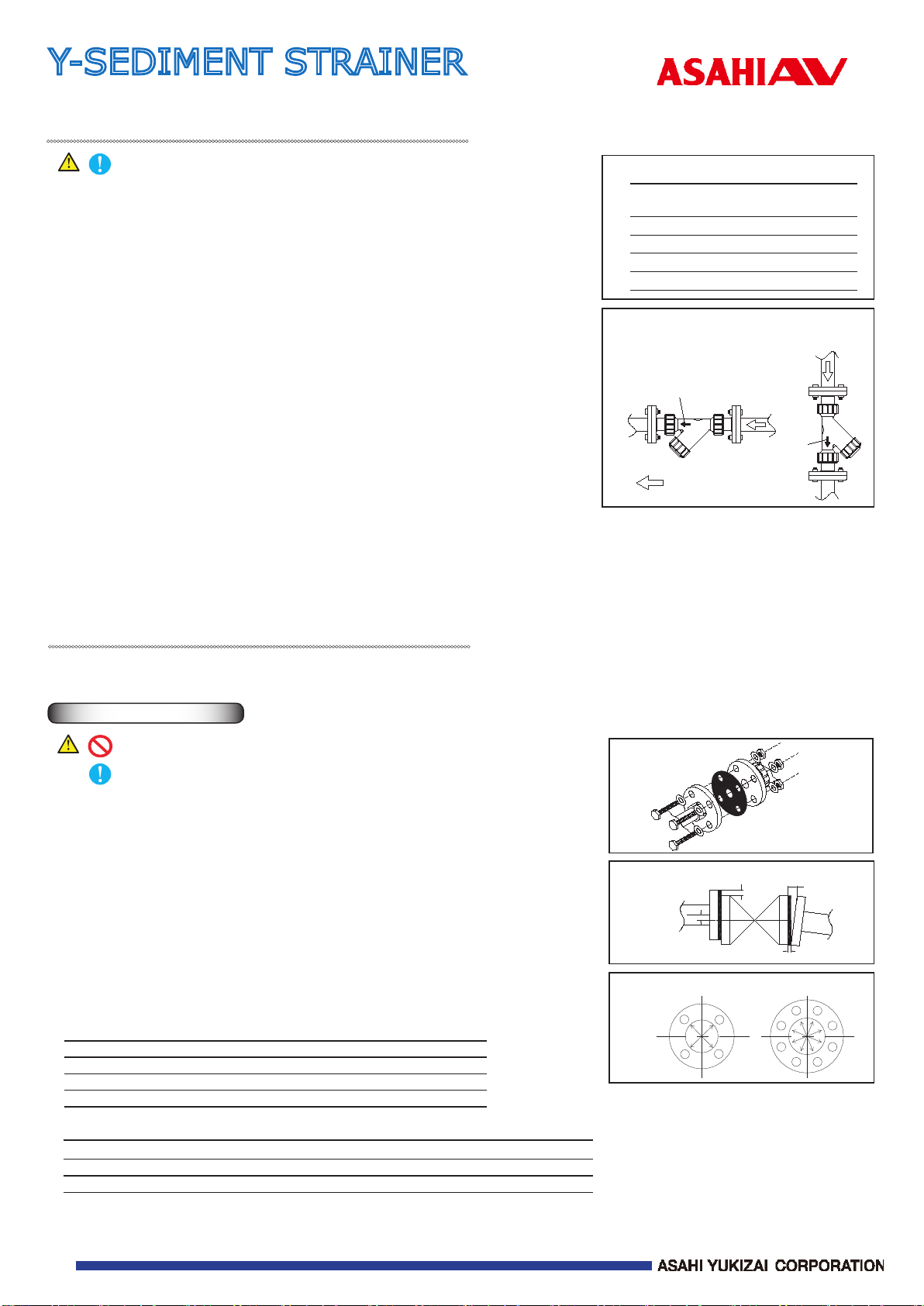

The connection method of the SEDIMENT STRAINER, there are Flanged End, Socket End, Threaded End. Install according to

the preferred method of joining for the particular application. As for details, refer to the User's manual separately.

-Take care not to over-tighten the Union Nut. (The valve can be damaged.)

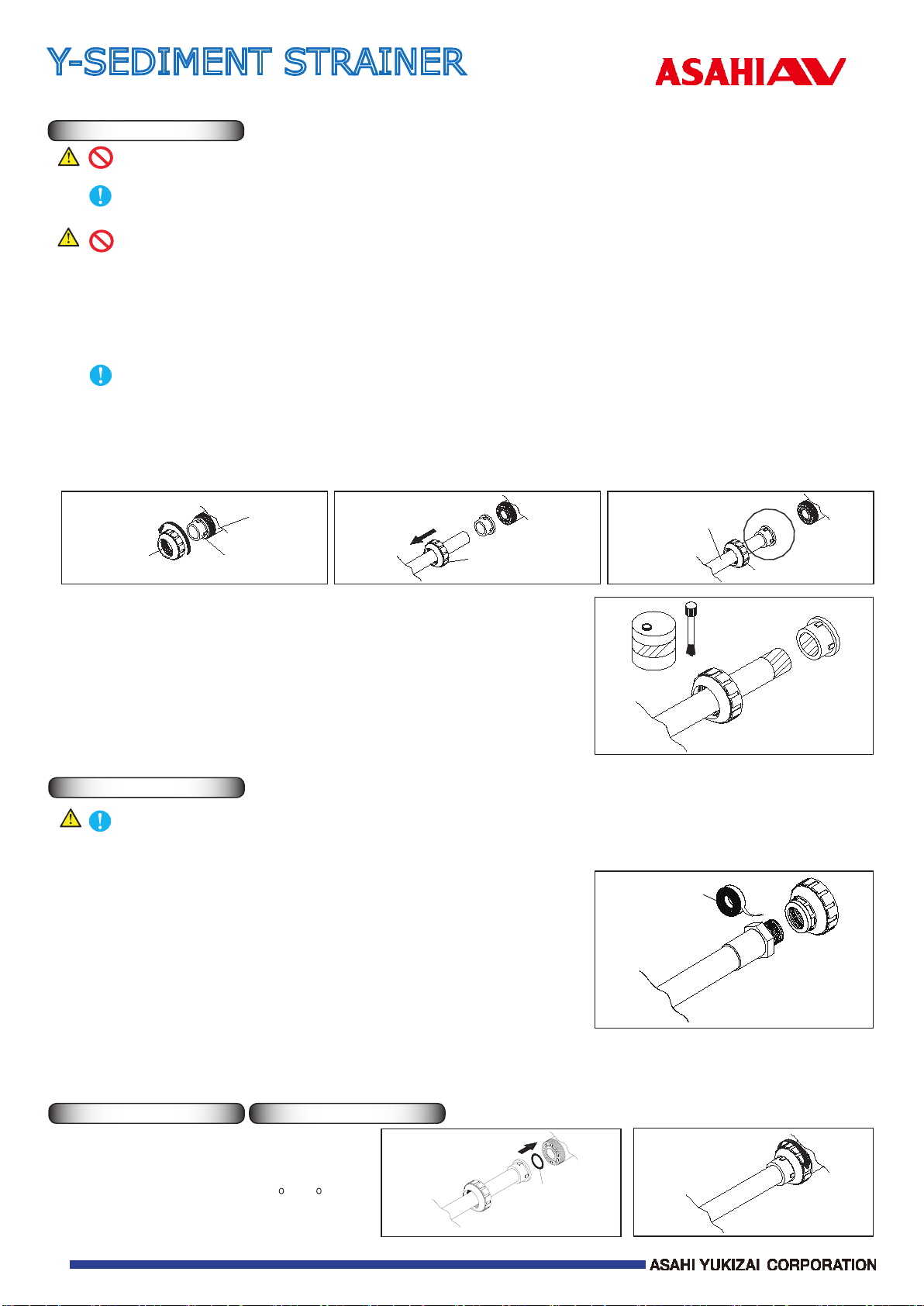

-The parallelism and axial misalignment of the ange surface should

be under the values shown in the following table to prevent damage to

the valve.(A failure to observe them can cause destruction due to stress

application to the pipe)

-Use at faced anges for connection to AV Valves.

-Ensure that the mating anges are of the same standards.

-Be sure to use sealing gaskets (AV Gasket), bolts, nuts, and washers

and tighten them to specied torques.

1. Cleaning: Conrm the ange face area is clean and free of dirt or

foreign materials.

2. Set the AV gasket between the anges. Insert washers and bolts

from the pipe side, insert washers and nuts from the valve side, then

temporarily tighten them by hand. Tighten the bolts and nuts gradually

with a torque wrench to the specied torque level in a diagonal manner.

Table. 3 < Recommended Torque Value > Unit: N・m {kgf・cm} [lb・inch]

Nom. Size 15, 20 (1/2"-3/4") 25 - 40 (1"-1 1/2") 50, 65 (2", 2 1/2") 80, 100 (3", 4")

PTFE, PVDF coated

17.5 {179} [155] 20.0 {204} [177] 22.5 {230} [200] 30.0 {306} [266]

Rubber 8.0 {82} [71] 20.0 {204} [177] 22.5 {230} [200] 30.0 {306} [266]

Table. 2 < Axial Misalignment and Parallelism of Flanged face > Unit: mm (inch)

Nom. Size Axial Misalignment Parallelism (a-b)

15 - 32 (1/2"-1 1/4") 1.0 (0.04") 0.5 (0.02")

40 - 80 (1 1/2"-3") 1.0 (0.04") 0.8 (0.03")

100 (4") 1.0 (0.04") 1.0 (0.04")

Fig.3

(Axial Misalignment) (Parallelism)

a

Fig.2

User's Guide

For the Owner and the Installing Contractor

Serial No. :UA-006E

Fig.1

Horizontal Piping Vertical Piping

Table.1 <Permissible ow speed>

Nominal Size

mm (inch)

Permissible Flow

Speed (m/s)

15 - 25 (1/2"-1") Less than 5m/s

32 - 50 (1 1/4", 2") Less than 3m/s

65, 80 (2 1/2", 3") Less than 2m/s

100 (4") Less than 1.5m/s

Direction of Flow

Designation

Designation

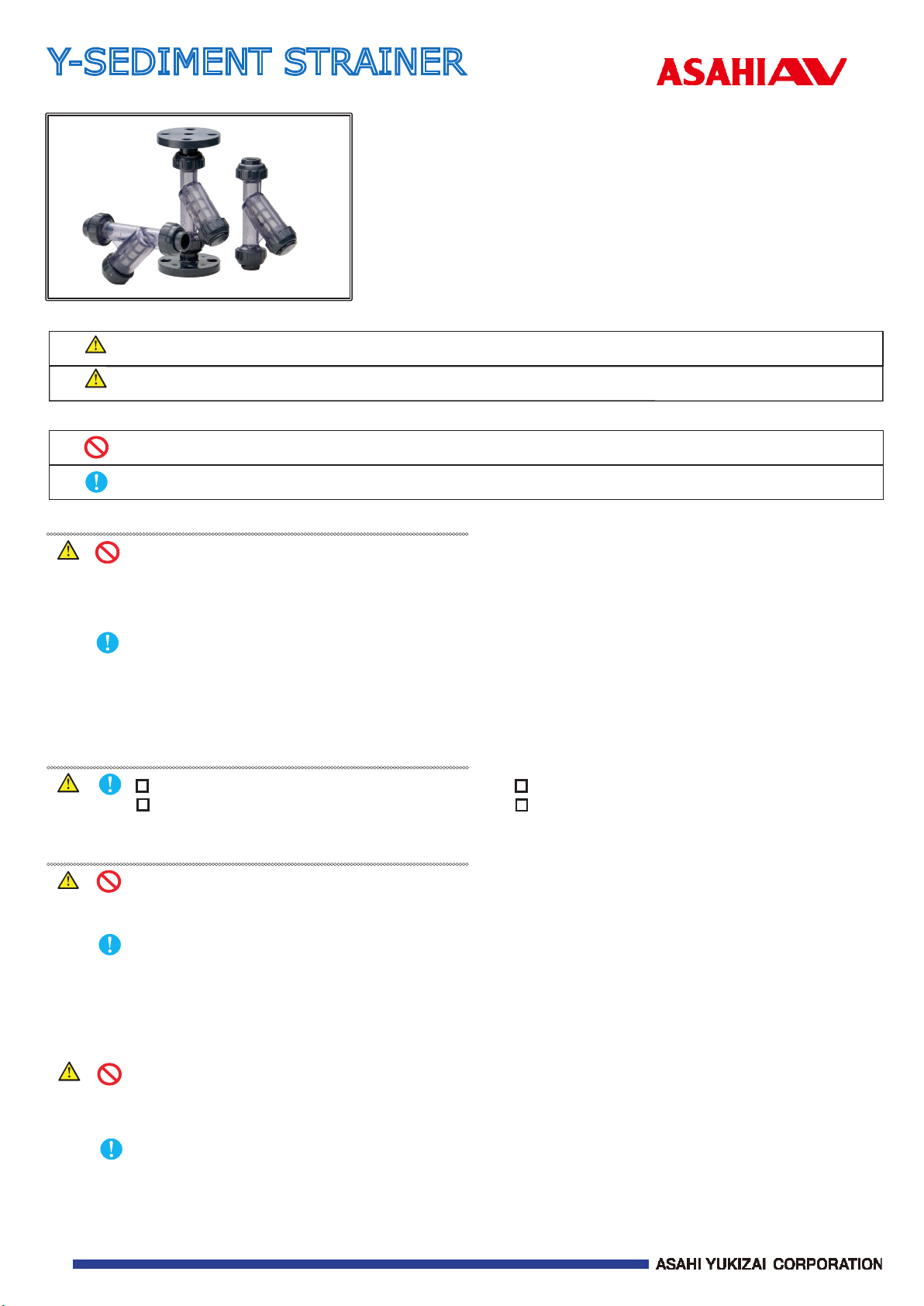

Y-SEDIMENT STRAINER