ASSEMBLY, INSTALLATION, OPERATION &

MAINTENANCE MANUAL

9.4M Earth Station Antenna

OM94 Revision M Page iv

The prerequisite information necessary for the 9.4m ESA can be found in this section. Furthermore, this

section should be reviewed before performing the installation, operation, or maintenance. Warnings,

recommended tools, and the antenna parts can be verified and/or determined with such a review.

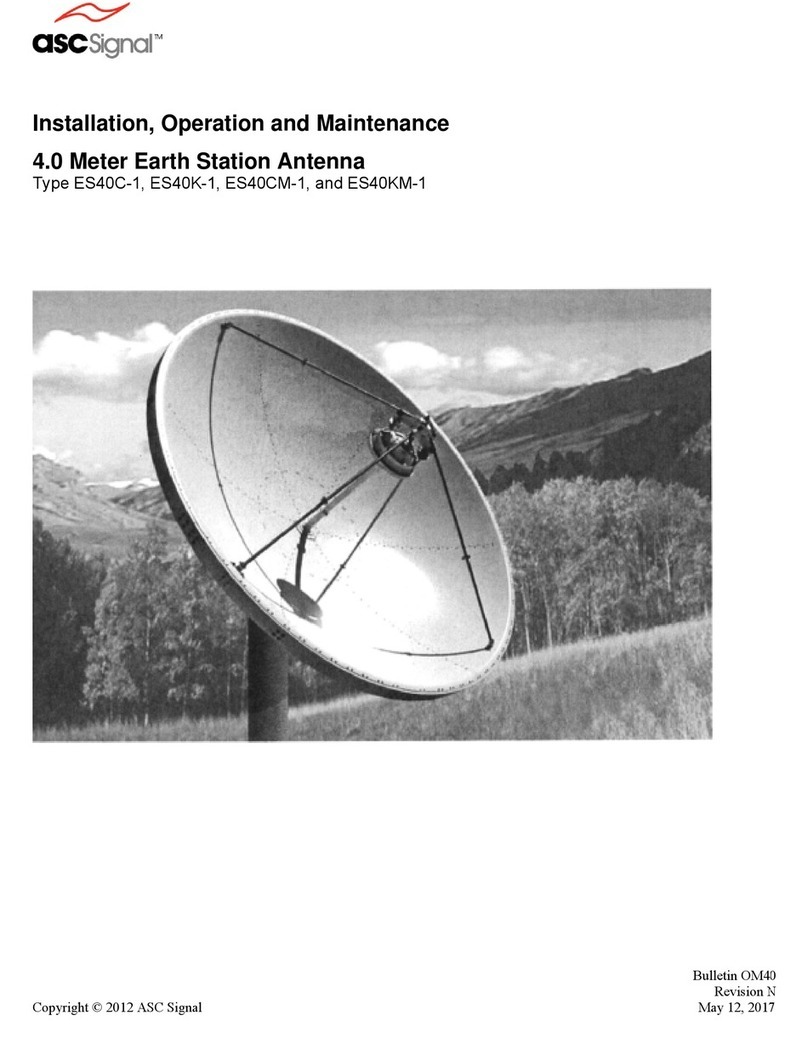

General Product Description

The 9.4m ESA provides high gain and exceptional pattern characteristics. The electrical performance and

exceptional versatility provides the ability to configure the antenna with your choice of combining network.

That versatility is provided at the time of initial purchase, as well as in the future, as your satellite

communication requirements evolve.

The aluminum reflector is precision formed for accuracy and strength, requiring minimal assembly. The

reflector assembly is 31-feet (9.4-meters) in diameter and segmented in a twenty panel configuration to

reduce shipping volume and facilitate transport to remote sites. Reflector panels are conversion coated and

painted with a flat white paint.

The versatile pedestal mount can be purchased with motorizable capabilities. The pedestal mount features

over 180° Azimuth coverage in continuous 120° overlapping ranges and executes 90° (0-90°) continuous

Elevation adjustment. This large adjustment range provides non-critical foundation orientation and the

ability to view geostationary satellites from horizon-to-horizon, from any location worldwide.

The motorizable pedestal mount features self-aligning bearings for the Elevation pivots, resulting in "zero"

backlash. This mount can be operated manually, but has the ability to be upgraded for motorized operation,

including step-tracking or SmarTrack®applications. The Az/El jackscrews are equipped for integration with

the optional motor drive systems. A cross-axis grounding kit is supplied with each mount to ensure electrical

interconnectivity of the complete structure.

ES94MPEXKA-1

The 9.4 m Earth Station Antenna provides high gain and exceptional radiation pattern characteristics. The

outstanding electrical performance and versatility provides the ability to configure the antenna with your

choice of combining network.

The 9.4 m antenna has incorporated Subreflector Tracking (SRT) to continuously maintain the antenna

pointed at the satellite. This is also controlled by a microprocessor.

The aluminum reflector is precision formed for accuracy and strength, requiring minimal assembly time.

The reflector assembly is 9.4 meters (31 feet) in diameter and segmented in a 20-piece configuration to

reduce shipping volume and facilitate transport to remote sites. Reflector panels are conversion converted

and coated with a flat white paint.

The versatile extended azimuth pedestal mount is provided with motorizable Elevation and Azimuth

capabilities. The pedestal mount features over 220° continuous Azimuth coverage, and executes 0° - 90°

continuous Elevation adjustment. This large adjustment range provides the ability to view geostationary

satellites from almost any location worldwide. The Azimuth drive consists of dual high stiffness gear motors

driving a four point contact azimuth bearing with integral 130 tooth involute gear cut in the outer race. The

dual azimuth drives are torque biased to eliminate backlash. The Elevation axis has dual 20-ton, anti-

backlash jack screws mechanically linked to a single elevation drive motor.

The aluminum enclosure and hot-dipped galvanized steel mount maintain pointing accuracy and ensure

durability and reliability. The antenna and standard manual mount with enclosure will survive 125 mph (200

km/h) wind, in any position of operation, without sustaining damage or permanent deformation in moderate

coastal/industrial areas. Severe conditions require additional protection.