ASC Gruvlok 3006 User manual

Gruvlok®Roll Groover

3006 & 3006C Manual

We pride ourselves in providing the finest quality pipe products and services with integrity

and dedication to superior customer service at all levels.

We provide expertise and product solutions for a wide range of applications, from

plumbing and mechanical, HVAC, industrial and fire protection to mining, and oil and gas.

Our comprehensive line of products includes: grooved pipe couplings, grooved and plain-

end fittings, valves, cast and malleable iron fittings, forged steel fittings, steel pipe nipples

and couplings, pipe hangers and supports, channel and strut fittings, mining and oil field

fittings, along with much more.

As an additional benefit to our customers, Anvil offers a complete and comprehensive

Design Services Analysis for mechanical equipment rooms, to help you determine the

most effective and cost-efficient piping solutions for your pipe system.

At Anvil, we believe that responsive and accessible customer support is what makes the

difference between simply delivering products — and delivering solutions.

For over 160 years, Anvil has worked diligently to build

a strong, vibrant tradition of making connections —

pipe to pipe and people to people.

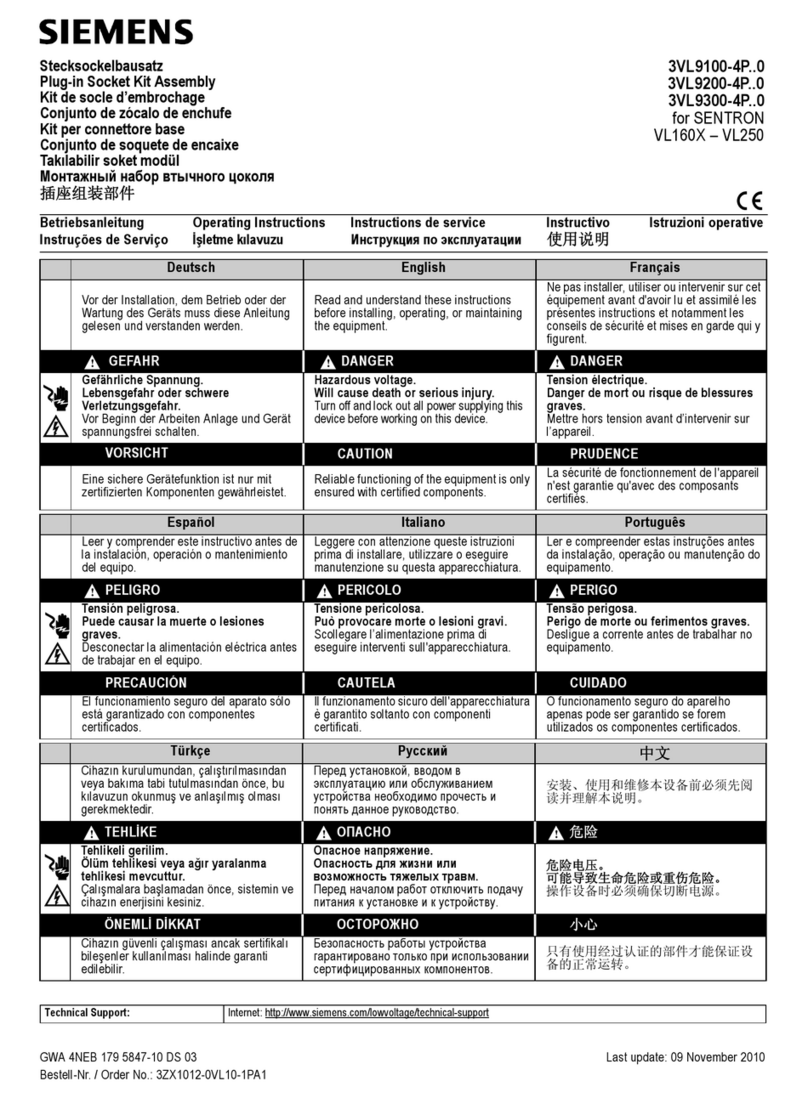

SAFETY INSTRUCTIONS 04

GROOVER DESCRIPTION 05

INSTALLING SUPPORT LEG ASSEMBLY 06

PIPE SET-UP AND POSITIONING 07

SETTING GROOVE DIAMETER 08

GROOVING IPS STEEL PIPE 09

GROOVING CTS COPPER SYSTEM 10

GROOVING ROLL CHANGE 11

GROOVER MAINTENANCE 13

REPLACEMENT PARTS 14

GROOVE SPECIFICATIONS 15

TROUBLESHOOTING 17

Carefully read and understand instructions before assembling

and operating the Groover(s). Become thoroughly familiar

with the Groover operation, usage and possible hazards

specific to the Groover(s).

IMPORTANT SAFETY NOTICE

3006/3006C ROLL GROOVER

4

SAFTETY INSTRUCTIONS

A. GENERAL

1. Carefully read and understand these operating instructions

before assembling and operating the Groover.

2. Read and follow the safety labels on the Groover.

3. Understand the function and the location of all power and

grooving controls before using the Groover.

B. OPERATOR SAFETY

1. Do not wear loose clothing, loose sleeve cuffs, loose

fitting gloves, or jewelry that could get caught in moving

parts.

2. Wear safety glasses and safety shoes.

3. Tie-up or cover long hair.

4. Wear ear protection if using the Groover in a high noise

area or for prolonged periods of grooving.

5. Do not operate the Groover if you are tired from fatigue

or medication.

6. Do not allow horseplay around the Groover.

C. GROOVER SET-UP

1. Provide a safe work area. Keep the work area well lighted

and maintain a clear, uncluttered space for operation of the

Groover.

2. Do not use the Groover in wet or damp locations.

The floor area around the Groover must be dry and free

of slippery materials.

3. Set-up the Groover on firm, level ground. Do not locate the

Groover on sloped or irregular ground conditions.

4. Remove all tools, wrenches, etc., from the Groover and

power drive base before applying power to the Groover.

5. Do not attempt to lift the Groover by yourself.

6. Use the Model 3006/3006C Groover only with a Ridgid*300

Power Drive with 38 RPM operation.

7. The Model 3006/3006C Groover must be properly mounted

on the Ridgid 300 support arms and the Groover driveshaft

firmly tightened Into the Ridgid 300 chuck jaws.

8. Unplug the Ridgid 300 drive power cord prior to servicing or

changing groover parts.

THE GRUVLOK®MODEL 3006/3006C ROLL GROOVERS ARE TO BE USED ONLY FOR ROLL GROOVING OF PIPE.

These operating instructions provide important information for the safe operation of the Groover to protect the operator from

possible, serious injury. The Groover is designed for safe, reliable operation. However, unforeseen circumstances, impossible

to predict, could result in an accident. Following the information in these operating instructions will permit safe operation of

the Groover.

D. GROOVER OPERATION

1. All safety guards must be in place. Never operate the Groover

with the guards removed.

2. Do not operate the Groover without a foot switch. A foot switch

is required for safe operation of the Groover.

3. Operate the Groover only from the pump side of the Groover.

4. Keep hands away from guide and grooving rolls. The Groover

is designed for "hands clear" grooving.

5. Maintain balanced footing keeping the foot switch within comfortable

reach. Do not reach across the Groover or pipe. Keep hands and

clothing away from all moving parts.

6. Do not place excessive force on the hydraulic pump handle.

Follow grooving instructions for safe Groover operation.

7. Provide support for piping spool pieces through the use of an

appropriate pipe stand properly fastened to the floor or ground.

8. Use the Groover only for the size and wall thickness pipe for which

it was designed.

9. Do not operate the Groover if any part of the Groover is damaged

or broken.

10. Do not attempt to groove pipe shorter than 5" in length.

11. Keep all visitors and bystanders at a safe distance from the

Groover, pipe and power cords.

E. ELECTRICAL SAFETY

1. The Ridgid®300 Power Drive should be connected to an integrally

grounded electrical system protected by a Ground Fault Current

Interrupter (GFCI).

2. Never use worn or damaged cords.

*“RIDGID” is a registered trade mark of Emerson Electric Company.

CAUTION

BUILDING CONNECTIONS THAT LAST

5

GROOVER DESCRIPTION

*“RIDGID” is a registered trade mark of Emerson Electric Company.

Note: See Section XI for further details of parts for the 3006 and 3006C Roll Groover.

A. 3006 STANDARD EQUIPMENT

Roll Groover complete with Adjustable Support Leg Assembly and

roller sets for grooving 2"-6" and 8"-12" steel pipe, Steel/CTS Dual

Guide Roll Assembly, hydraulic pump with pressure gauge, and two

depth adjustment gauges. This unit is designed for direct attachment

to your Ridgid®300 Power Drive. Complete with comprehensive setup,

operating and troubleshooting instructions.

Shipped in a reusable wooden storage crate.

Approximate shipping weight: 225 pounds.

Required Ridgid® 300 Power Drive not included.

B. 3006 OPTIONAL EQUIPMENT

CTS COPPER SYSTEM:

• 2"- 8" CTS Copper System Grooving Rolls, 2"- 4" CTS Depth

Gauge, and 5"- 8" CTS Depth Gauge.

A. 3006C STANDARD EQUIPMENT

Roll Groover complete with Adjustable Support Leg Assembly and

CTS Copper System roller set for grooving 2"-6" copper tube, CTS

Guide Roll Assembly, hydraulic pump with pressure gauge, and 2"-6"

Universal Diameter Gauge. This unit is designed for direct attachment

to your Ridgid®300 Power Drive. Complete with comprehensive setup,

operating and troubleshooting instructions.

Shipped in a reusable wooden storage crate.

Approximate shipping weight: 215 pounds.

Required Ridgid®300 Power drive not included.

B. 3006C OPTIONAL EQUIPMENT

STEEL OPTION:

• Consisting of 2"-6" and 8"-12" roll sets, Steel/CTS Dual

Guide Roll Assembly, and two depth adjustment gauges

1. All wall thicknesses shown are the maximum wall thicknesses for the indicated pipe material.

2. Minimum wall thickness for each pipe material and size is:

Steel: 2"-12"Schedule 10

Stainless Steel: 2"- 12" Schedule 10S, 40S

Copper: 2"- 2/" - Type M

3"- 8" - Type DWV

3. Please contact an Anvil Representative for information on grooving alternate materials and wall thickness.

GROOVER CAPABILITY

Pipe Material Pipe Size/Wall Thickness (Schedule)1,2

In. 22 1⁄23456810 12

DN(mm) 50 65 80 100 125 250 200 250 300

Steel Schedule 10, 40 0.188"0.219"

Stainless Steel Schedule 10S, 40S

Copper K, L, M & DWV

MODEL 3006/3006C STEEL PIPE GROOVING TIMES (MINUTES: SECONDS)

Pipe Size (In./DN(mm))/Max Steel Pipe Wall Thickness

2 2 1⁄23456810 12

50 65 80 100 125 150 200 250 300

0:20 0:20 0:25 0:30 1:00 1:20 1:35 1:50 2:20

C. 3006/3006C GROOVER CAPABILITY

D. GROOVING TIMES

This chart shows approximate grooving times with the groover set-up for the proper size and groove diameter and the pipe properly positioned on the

groover. The times shown are average times from the start of rotation of the pipe in the grooving rolls to completed groove.

3006/3006C ROLL GROOVER

6

INSTALLING SUPPORT LEG ASSEMBLY

GROOVER SET-UP MODEL 3006/3006C

Removal of the Groover from the wooden crate and mounting of the Groover to the Ridgid® 300 drive should be accomplished

by 2 persons. To avoid possible injury DO NOT ATTEMPT TO LIFT THE FIGURE 3006/3006C ROLL GROOVERS WITH LESS THAN

TWO PEOPLE .

1. Slide round tubing over left support arm of Ridgid®300 tool so that flat plate

is under both arms. Push tubing back as far as allowed on the arms.

2. Insert each lower leg (with feet) into each upper leg so that they overlap by

approximately 12 inches. Hand tighten the hex head bolts to temporarily

hold in place.

3. Starting with the right leg, insert each upper leg into socket under the flat

plate. Loosen the hex bolt holding the lower leg and adjust so that the feet

are pointing out from the Ridgid®300 tool. Repeat with left leg. Tighten the

hex bolts on the upper leg and socket to lock legs in place. (9

/

16" wrench)

Base should look like assembled picture.

4. Slide 3006/3006C tool onto Ridgid®300 Tool as described in Section IV.

Back of tool should sit over flat plate with sockets underneath.

Use the Adjustable Support Leg Assembly for the 3006/3006C Roll

Groover whenever long pieces of pipe/tubing or heavier wall thicknesses are

being grooved.

The gruvlok® model 3006/3006c roll groovers are designed for use with a ridgid® 300 power drive

1 4

2 5

3 6

Extend the mounting arms of

the Ridgid® 300 power drive,

approximately 12" out from

the body of the drive.

Align the flats on the triangular

shaft tailpiece with the Ridgid®

300 chuck jaws and slide the

Groover back into the chuck jaws.

Securely tighten the chuck jaws.

Grasp the Groover base on

opposite sides, lift the Groover

out of the shipping box and place

the mounting wings in the

Groover base over the extended

mounting arms.

Push extension arms in flush with

the groover mounting base front.

Align the flats on the triangular

shaft tailpiece with the Ridgid®

300 chuck jaws and slide the

Groover back into the chuck jaws.

Securely tighten the chuck jaws.

Position the pump to the desired

position for ease of operation.

Tighten bolt to lock pump in

position or if desired, back off

just slightly to permit pump to

be oriented by operator to most

comfortable position during

Groover operation.

(⁄" wrench)

CAUTION

BUILDING CONNECTIONS THAT LAST

7

PIPE SET-UP & POSITIONING

Set both rubber guide rolls located on

the front of the Groover, into the

correct holes for the size pipe being

grooved. (/" allen wrench)

Note: For CTS Copper System, use the

Steel/CTS Dual Guide Roll Assembly.

Close the release valve on the hydraulic

pump by turning the knob clockwise.

Pump the hydraulic hand pump to

lower the top grooving roll into light

firm contact (approx. 100 psi) with

the pipe.

Make sure that the groove diameter

stop (consisting of two / -14 hex

nut located on the top back of the

Insert pipe over the bottom roll (groove

roll) positioning the pipe flush against

the front flange of the bottom roll.

Using the slot on top of the roller plate

adjustment rod, raise (counterclockwise

rotation) the guide roll mounting plate

sufficiently to ensure that the top grooving

roll makes contact with the pipe prior to

guide roll contact.

The Groover should be leveled for best

grooving results. Place level on top of

hydraulic ram as shown and adjust the

support legs as required to level the

Groover and provide a firm fixed base

location for both the Groover and power

drive.

Use one (1) roller pipe stand to support the pipe. Adjust the outboard

pipe stand to assure proper contact with the guide rolls. Pipe stand

should be 65 - 75% of the pipe length away from Groover. Looking at

the front of the Groover, the pipe stand should be positioned to angle

the tube approximately 0° to /° downward, away from the front of

the Groover and /° to the left side at the Groover. See Figures Below.

1

4

5

2

6

3

Groover Centerline

Pipe Centerline 0° to ⁄° Toward user

Groover Centerline

Pipe Centerline 0° to ⁄° down

The Model 3006 Groover comes with 2"-6" Steel grooving rolls installed unless otherwise requested on your order. The Model 3006C

Groover comes with 2"-6" CTS Copper grooving rolls installed. To change grooving rolls for other sizes, for copper tubing, or for steel pipe,

refer to page 13 for grooving rolls and guide roll plate changeout.

Groover) is not in contact with the top surface of the housing. If contact is noted,

release hydraulic pressure by turning the release valve knob counterclockwise

allowing the groover head to raise upward. Turn the nut counterclockwise

sufficiently to allow clearance between the bottom of nut and top of housing

when the top grooving roll is in contact with the pipe.

SIDE VIEW

TOP VIEW

Note: For CTS Copper System, use the CTS Depth Gauges.

Turn the lowest hex nut (groove diameter stop) to snug against

the surface of the groove diameter gauge. Turn the jam nut (upper

hex nut) to snug with lower hex nut (groove diameter stop).

Release the pump pressure by turning the pump relief valve

counter-clockwise and remove the groove diameter gauge

A. WITH DEPTH GAUGE A. OPTIONAL METHOD - WITHOUT DEPTH GAUGE

3006/3006C ROLL GROOVER

6

8

SETTING GROOVE DIAMETER

Slide the U-shaped depth

gauge, for the pipe size to be

grooved under the lowest

hex nut (groove diameter

stop) at the top back of the

Groover. Each gauge is

marked with various pipe size

ranges. Place the correct

pipe size area, for the size

of pipe being grooved, under

the lower hex nut (groove

diameter stop).

Increase the pump pressure

so that the pipe is firmly held

between the groove and

drive rollers without forming

a dent.

Turn the lowest hex nut

(groove diameter stop)

to snug against the top

surface of the Groover.

Set-up and position the pipe as shown on page 7.

Maintain approximately 100 psi pump pressure as established on

page 7 paragraph 4.

Back the hex nut (groove diameter stop) off the number of

turns specified in the accompanying chart. Turn the jam nut

(upper hex nut) to snug with lower hex nut (groove diameter

stop). Release the pump pressure by turning the pump

release valve counterclockwise.

HEX NUT TURNS

Pipe Diameter

22 1

/

23456810 12

Portion of Turn 1

/

2

1

/

2

1

/

2

1

/

2

2/

3

2/

3

2/

3

2/

3

5/

6

HEX NUT ADJUSTMENT GROOVE DIAMETER CHANGE

Turns Inches

/ .024"

⅓ .048"

½ .071"

⅔ .095"

/ .119"

1 .142"

ensure grooves produced are within specified limits.

Note: Adjustment of the Hex Nut (groove diameter stop) will produce the

below listed groove diameter changes.

BUILDING CONNECTIONS THAT LAST

9

GROOVING IPS STEEL PIPE

Maintain grooving force

until the hex nut (groove

diameter stop) comes into

full, firm contact with the

top of the groover base

head. Allow the pipe to

rotate 1 to 2 revolutions

assuring completion of the

groove. Release the foot

switch to allow the pipe to

stop rotation.

Open the hydraulic hand

pump release valve by

turning counterclockwise.

Remove the pipe from the

Groover.

Using a pi tape, check the

groove diameter produced

and compare it to

specifications presented on

page 10. If required, adjust

groove diameter stop to

Recheck for correct pipe

set-up and position on the

bottom roll and adjust as

required. Close the release

valve on the hydraulic hand

pump and increase pump

pressure so that the groove

roll is in firm contact (Sch.

10 approx. 400 psi /Sch.

40 approx. 800 psi) with

the pipe OD.

Check to see that the Ridgid®300 drive directional switch is set to reverse

(clockwise rotation of the pipe looking at the front of the Groover.)

start the drive motor by depressing the foot switch to rotate the pipe.

Assure that the pipe is tracking firmly against the back of the bottom

roll.

With the pipe rotating,

increase grooving force by

slowly pumping the

hydraulic pump handle to

raise pump pressure. Do

not pump too fast.

Continue to raise the

pressure until a groove

starts being formed. Use

the following table as a

guide for grooving

pressures.

STEEL PIPE

RECOMMENDED SET-UP PRESSURE

Pipe Size Wall Set-up Pressure

Inches Schedule PSIG

2" - 6" 10 1,200-1,600

8" 10 4,600-5,000

10" .188" 4,600-5,000

12" .219" 4,600-5,000

2" 40 2,800-3,200

2 /"- 4" 40, 40S 4,200-4,600

5"- 8" 40 4,600-5,000

5"- 6" 40S 4,600-5,000

Clockwise rotation – Increase groove diameter

Counterclockwise rotation – Decrease groove diameter

After adjustment of the groove diameter stop, if the groove diameter is

large (i.e. shallow groove depth), place the pipe end back into the

Groover and complete the same groove to the new diameter stop

setting. If the groove diameter is small (i.e. deep groove depth), put an

unfinished end into the Groover and roll a new groove. Recheck the

groove diameter for conformance to grooving specifications.

3006/3006C ROLL GROOVER

10

200 psi) with the tube OD. Check to see that the Ridgid®300 drive

directional switch is set to reverse (clockwise rotation of the tube looking

at the front of the Groover.)

Start the drive motor by depressing the foot switch to rotate the

tube. Assure that the tube is tracking firmly against the back of the

bottom roll.

GROOVING CTS COPPER SYSTEM

Recheck for correct tube

set-up and position on the

bottom roll and adjust as

required. Close the release

valve on the hydraulic hand

pump and increase pump

pressure so that the groove

roll is in firm contact (approx.

Maintain grooving force until the

hex nut (groove diameter stop)

comes into full, firm contact with

the top of the groover base head.

Allow the tube to rotate 1 to 2

revolutions assuring completion

of the groove. Release the foot

switch to allow the tube to stop

rotation.

With the tube rotating,

increase grooving force by

slowly pumping the hydraulic

pump handle to raise pump

pressure. Do not pump too

fast. Continue to raise the

pressure until a groove

starts being formed. Use

the following table as a guide

for grooving pressures.

Open the hydraulic hand pump

release valve by turning

counterclockwise. Remove the

tube from the Groover.

Using a pi tape, check the

groove diameter produced and

compare it to specifications

presented on page 17.

14

2

5

6

3

HEX NUT ADJUSTMENT GROOVE DIAMETER CHANGE

Turns Inches

/ .024"

⅓ .048"

½ .071"

⅔ .095"

/ .119"

1 .142"

Clockwise rotation – Increase groove diameter

Counterclockwise rotation – Decrease groove diameter

After adjustment of the groove diameter stop, if the groove diameter is

large (i.e. shallow groove depth), place the tube end back into the

Groover and complete the same groove to the new diameter stop

setting. If the groove diameter is small (i.e. deep groove depth), put an

unfinished end into the Groover and roll a new groove. Recheck the

groove diameter for conformance to grooving specifications.

CTS COPPER SYSTEM

RECOMMENDED GROOVING PRESSURE

Tube

Size

COPPER TUBING TYPE

K

Pressure

L

Pressure

M

Pressure

DWV

Pressure

In. PSI PSI PSI PSI

2" 900 800 600 –

21/

2" 1,100 900 800 –

3" 1,100 900 800 400

4" 1,400 1,200 900 500

5" 1,800 1,400 1,100 700

6" 1,500 1,100 800 900

8" 2,000 2,400 1,500 1,100

If required, adjust groove diameter stop to ensure grooves produced are

within specified limits.

Note: Adjustment of the Hex Nut (groove diameter stop) will produce the

below listed groove diameter changes.

BUILDING CONNECTIONS THAT LAST

Place one hand under the guide

roll mounting plate. Using a /"

wrench, remove the hex nut from

the top of the adjustment shaft

protruding from the top of the

groover head.

Cradle one hand under the

top roll and pull the top roll

shaft from the front.

CAUTION: The top roll is

heavy. Brace your hand to

receive the weight of the top

roll. As the shaft disengages

from the top roll, the top roll

will fall into your hand.

Loosen the set screw on the sliding

sleeve located between the front

and back bearings on the bottom

shaft.(/" allen wrench) If you

cannot see the set screw, turn the

power back on to the Ridgid® 300

drive and use the foot switch to

rotate the sleeve until the screw

Remove the guide roll mounting

plate by lowering the shaft out of

the mounting block at the front

of groover head.

Slide the sleeve toward the back

bearing, revealing the dowel pin

hole in the shaft. Push the dowel

pin completely out of the shaft.

(⅜" pin driver)

Pull the bottom roller out from the

front of the Groover.

1

3

1

2

2

3

C. BOTTOM (DRIVE) ROLL

A. GUIDE ROLL MOUNTING PLATE

GROOVING ROLL CHANGE - ROLL REMOVAL

Note: First remove the guide roll mounting plate, then the top groove roll and last the bottom drive roll.

NOTE

Loosen (approximately 5

turns) the shaft locator set

screw in the groover head to

disengage the set screw from

the slot in top roll shaft (/"

allen wrench)

Screw the ¼"-20 thumb

screw (stored on the pump

side of the main housing)

into the drilled and tapped

hole in the front of the top

shaft.

1

2

B. TOP (GROOVED) ROLL

Note: There is no need to unchuck the Groover from the Ridgid®300 drive.

4

Remove thumb screw from top shaft and return to storage location.

can be seen. Then turn off the power to the Ridgid® 300 drive and unplug it.

DO NOT PROCEED FURTHER UNTIL THE MACHINE HAS BEEN UNPLUGGED.

Lower the top roll from between the front and back plates of the grooving

head.

3006/3006C ROLL GROOVER

12

Insert the bottom roll shaft

through the front of th groover.

Insert the dowel pin until it is

flush with the bottom shaft

surface.

Rotate the bottom roll to align

the dowel pin hole on the side of

the machine.

Slide the retaining sleeve over

the dowel pin hole and tighten

the set screw. (⁄₃₂" allen wrench)

Tighten the locator socket

setscrew (⁄₃₂" allen wrench).

This will align the V-groove with

the locator setscrew in the

groover head. Care should be

taken to avoid contacting the

plain diameter of the shaft.

Insert the adjustment shaft

from the bottom, into the hole in

the mounting block at the front

of the groover head.

Slide the shaft up to expose the

threaded portion at the top of

mounting block.

Using a ⁄" wrench, install and

snug the hex nut on the top of the

adjustment shaft.

1

2

3

1

3

4

2

3

C. BOTTOM (DRIVE) ROLL

A. GUIDE ROLL MOUNTING PLATE

GROOVING ROLL CHANGE - ROLL INSTALLATON

Raise the groove roll between

the front and back plates of

the groover head. The deep

slot in the top roller should be

located toward the back of

the groover.

Insert the top shaft into the

front of the machine so that

the V-groove is towards the

front. Push the shaft

backward until the front is

approximately even with the

front face of the machine.

1

2

B. TOP (GROOVED) ROLL

Select the correct mounting plate for either steel pipe or for copper tube.

BUILDING CONNECTIONS THAT LAST

Apply grease to front

bearing with a grease gun

with a ⁄" fitting

attachment to the lower

grease fitting on the left

side of the Groover.

Please contact your Anvil Representative to purchase replacement parts for

the Roll Groover. To ease ordering, an exploded drawing of each machine and

a complete replacement parts list is given in the next section. For a list of Anvil

Customer Service Centers, please see the last page of this booklet.

If you are having problems

maintaining hydraulic pressure,

verify that the release valve knob

on the pump is not hitting the

pump housing prior to the valve

closing completely.

There should be a slight gap

between the end of the knob and

the pump body. If there is not,

loosen the set screw on the knob

Apply grease to left key

with a grease gun with a

⁄" fitting attachment to

the upper grease fitting on

the left side of the

Groover.

Apply grease to right key

with a grease gun with a ⁄"

fitting attachment to the right

side of the Groover.

1

2

C. HYDRAULIC MAINTENANCE

A. GREASE FITTINGS B. REPLACEMENT PARTS

GROOVING MAINTENANCE

13

Routine maintenance of the model 3006/3006C Roll Groover requires periodic application of general purpose lithium grease (NLGI No. 2) to

the front bearing and keyways. Under normal usage, the bearing should be lubricated monthly and the keyways should be lightly lubricated on a

weekly basis. Frequency of lubrication should be increased in harsh environments.

3

and slightly pull it off the valve shaft so that the valve can be closed completely

without interference. Then tighten set screw to lock the knob in the proper

position. If this does not solve the hydraulic problem, please contact your l

ocal Anvil Representative for further instructions.

3006/3006C ROLL GROOVER

14

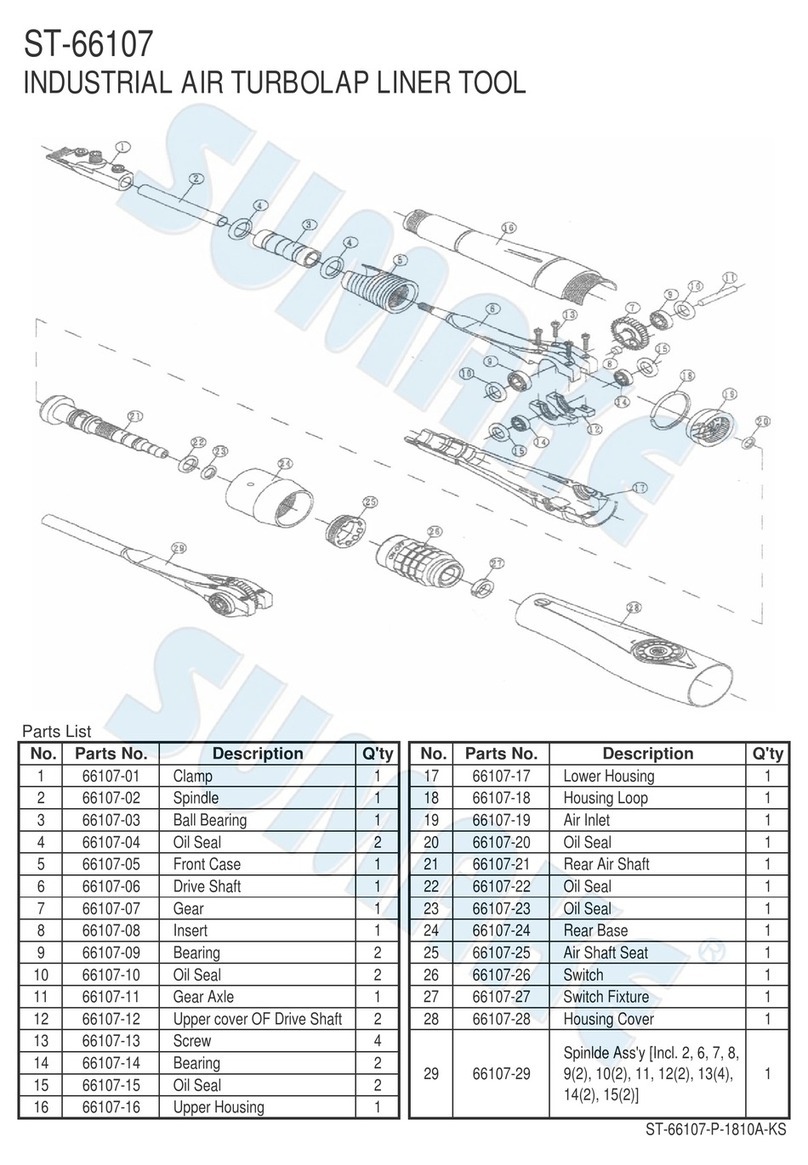

REPLACEMENT PARTS- 3006/3006C

1

1A

1E

1D

1B

12

10

11

9

8

7

6

5

13

14

16

15

4

2

3

2A

2B

2C

2H

2D 2E

2F

2G

1C

ID PART NAME PART NO

1 Pump Assembly GL11355

The Pump Assembly consists of the following:

1A Hydraulic Pump GL11356

1B Hydraulic Pressure Gauge GL11084

1C Cap Screw, ⁄-20, L= 5⁄8 GL11093

1D Pump Plate GL11297

1E Cap Screw, ⁄-20, L= ⁄" GL11230

2 Steel/CTS Dual Guide Roll Assy. GL11291

The Guard Assembly consists of the following:

2A Hex Nut, ⁄" GL11198

2B Guide Roll Guard GL11304

2C Guide Roll GL11106

2D Shoulder Bolt, ⁄"" GL11107

2E Washer, ⁄" GL11109

2F Flat Head Screw, ⁄-20, L=⁄"GL11108

2G Cap Screw, ⁄-20,L= ⁄" GL11230

ID PART NAME PART NO

3 Hex Bolt, ⁄-11, L= 1.5" GL11091

4 Cap Screw, ⁄-20,L= 1⁄2" GL11230

5 Safety Mesh GL11280

6 Hydraulic Ram GL11095

7 Jam Nut, ⁄-14 GL11277

8 Hex Nut, ⁄-14 GL11276

9 Top Roller:

2"-6" Steel Top Roller GL11285

8"-12" Steel Top Roller GL11300

2"-8" CTS Copper Top Roller (OPT)GL13803

10 Cup Point Set Screw, ⁄₁₆-18 GL11289

11 Dowel Pin GL11290

12 Cone Pt. Set Screw, ⁄₁₆-18 GL11066

ID PART NAME PART NO

13 Bottom Roller:

2"-6" Steel Bottom Roller GL11284

8"-12" Steel Bottom Roller GL11299

2"-8" CTS Copper

Bottom

Roller (OPT) GL13805

14 Top Shaft GL11281

15 Thumb Screw 1⁄4- 20, L=1" GL11056

16 Depth Gauge:

1"-4" Steel Depth Gauge GL11344

5"-12" Steel Depth Gauge GL11345

2"-6" CTS Depth Gauge(OPT) GL13852

8" CTS Depth Gauge (OPT) GL13853

Support Leg Assembly GL11374

2 REQUIRED

2 REQUIRED 2 REQUIRED

2 REQUIRED

3 REQUIRED

2 REQUIRED

2 REQUIRED

3 REQUIRED

BUILDING CONNECTIONS THAT LAST

15

NOTES:

COLUMN 1 - Nominal IPS Pipe size

COLUMN 2 - IPS outside diameter

COLUMN 3 - Gasket seat must be free from

scores, seams, chips, rust or scale

which may interfere with proper

sealing of the gasket. Gasket

seat width (Dimension A) is to be

measured from the pipe end to the

vertical flank in the groove wall.

COLUMN 4 - Groove width (Dimension B) is to be

measured between vertical flank of

the groove size walls.

COLUMN 5 - The groove must be of uniform

depth around the entire pipe cir-

cumference. (See column 6).

COLUMN 6 - Groove depth: for reference only.

Groove must conform to the groove

diameter “C” listed in column 5.

COLUMN 7 - Minimum allowable wall thickness

which may be roll grooved.

COLUMN 8 - Maximum allowable pipe end flare

diameter. Measured at the most

extreme pipe end diameter of the

gasket seat area.

GRUVLOK STANDARD ROLL GROOVE SPECIFICATIONS FOR STEEL & OTHER IPS SIZE PIPE

-1- -2- -3- -4- -5- -6- -7- -8-

Nominal

IPS

Pipe Size

Gasket Seat Groove Width Groove Diameter Groove Depth Min. Allow.

Wall Thickness

“T”

Max.

Flare

Diameter

Pipe OD “A” “B” “C” “D”

Actual Tolerance ±0.030/ ±0.76 ±0.030/ ±0.76 Actual Tol. +0.000 (Ref. Only)

In./DN(mm) In./mm +In./mm -In./mm In./mm In./mm In./mm -In./mm In./mm In./mm In./mm

2 2.375 +0.024 -0.024 0.625 0.344 2.250 -0.015 0.063 0.065 2.480

50 60.3 +0.61 -0.61 15.88 8.74 57.15 -0.38 1.60 1.7 63.0

21⁄22.875 +0.029 -0.029 0.625 0.344 2.720 -0.018 0.078 0.083 2.980

65 73.0 +0.74 -0.74 15.88 8.74 69.09 -0.46 1.98 2.1 75.7

3 3.500 +0.035 -0.031 0.625 0.344 3.344 -0.018 0.078 0.083 3.600

80 88.9 +0.89 -0.79 15.88 8.74 84.94 -0.46 1.98 2.1 91.4

31⁄24.000 +0.040 -0.031 0.625 0.344 3.834 -0.020 0.083 0.083 4.100

90 101.6 +1.02 -0.79 15.88 8.74 97.38 -0.51 2.11 2.1 104.1

4 4.500 +0.045 -0.031 0.625 0.344 4.334 -0.020 0.083 0.083 4.600

100 114.3 +1.14 -0.79 15.88 8.74 110.08 -0.51 2.11 2.1 116.8

5 5.563 +0.056 -0.031 0.625 0.344 5.395 -0.022 0.084 0.109 5.660

125 141.3 +1.42 -0.79 15.88 8.74 137.03 -0.56 2.13 2.8 143.8

6 6.625 +0.063 -0.031 0.625 0.344 6.455 -0.022 0.085 0.109 6.730

150 168.3 +1.60 -0.79 15.88 8.74 163.96 -0.56 2.16 2.8 170.9

8 8.625 +0.063 -0.031 0.750 0.469 8.441 -0.025 0.092 0.109 8.800

200 219.1 +1.60 -0.79 19.05 11.91 214.40 -0.64 2.34 2.8 223.5

10 10.750 +0.063 -0.031 0.750 0.469 10.562 -0.027 0.094 0.134 10.920

250 273.1 +1.60 -0.79 19.05 11.91 268.27 -0.69 2.39 3.4 277.4

12 12.750 +0.063 -0.031 0.750 0.469 12.531 -0.030 0.109 0.156 12.920

300 323.9 +1.60 -0.79 19.05 11.91 318.29 -0.76 2.77 4.0 328.2

T

B

D

C

OD

Flare

A

OUT OF ROUNDNESS: Difference between

maximum O.D. and minimum O.D. measured

at 90° must not exceed total O.D. tolerance

listed (reference column 2).

FOR IPS PIPE, the maximum allowable tolerance

from square cut ends is 0.03" for 2" thru 31⁄2";

0.045" for 4" thru 6"; and 0.060" for sizes 8"

and above measured from a true square line.

BEVELED-END PIPE in conformance with ANSI

B16.25 (371⁄2°) is acceptable, however square cut

is preferred.

GROOVE SPECIFICATION - STEEL

3006/3006C ROLL GROOVER

16

GROOVE SPECIFICATION - CTS COPPER SYSTEM

COLUMN 1 - Nominal tubing size ASTM B88

COLUMN 2 - Outside diameter of copper tubing per

ASTM B88. Allowable tolerance from

square cut ends is 0.030"/0.76mm

for sizes 2"-3"; 0.045”/1.14mm for

sizes 4-8"

COLUMN 3 - Gasket seat must be free from scores,

roll marks, indentations, grease and

dirt which may interfere with gasket

sealing.

COLUMN 4 - Groove width is to be free from chips,

dirt, etc. which may interfere with

proper coupling assembly.

COLUMN 5 - Groove diameter must be of uniform

depth for the entire circumference of

the tubing. (See column 6).

COLUMN 6 - Groove depth is for reference only;

the groove diameter must conform

to column 5.

COLUMN 7 - DWV (Drain, Waste and Vent Piping)

per ASTM B306.

COLUMN 8 - Maximum flare diameter is the OD at

the most extreme tubing diameter.

GRUVLOK CTS COPPER SYSTEM – ROLL GROOVE SPECIFICATIONS

-1- -2- -3- -4- -5- -6- -7- -8-

Nominal

Size

Tubing Outside Diameter Gasket Seat “A”

+/– 0.03 in.

+/– 0.76mm

Groove Width “B”

+0.03/–0.00 in.

+0.76/–0.00mm

Groove Diameter “C”

Nominal Groove

Depth “D”

Min.

Wall

“T”

Max.

Flare

Diam.

Actual Tolerance Actual Tolerance

+0.000

In. In./mm + In./mm – In./mm In./mm In./mm In./mm – In./mm In./mm In./mm In./mm

22.125 0.002 0.002 0.610 0.300 2.029 -0.020 0.048 0.058 2.220

54.0 0.05 0.05 15.5 7.6 51.54 -0.51 1.2 1.6 56.4

21⁄22.625 0.002 0.002 0.610 0.300 2.525 -0.020 0.050 0.065 2.720

66.7 0.05 0.05 15.5 7.6 64.14 -0.51 1.3 1.7 69.1

33.125 0.002 0.002 0.610 0.300 3.025 -0.020 0.050 DWV 3.220

79.4 0.05 0.05 15.5 7.6 76.84 -0.51 1.3 81.8

44.125 0.002 0.002 0.610 0.300 4.019 -0.020 0.053 DWV 4.220

104.8 0.05 0.05 15.5 7.6 102.08 -0.51 1.3 107.2

55.125 0.002 0.002 0.610 0.300 4.999 -0.020 0.053 DWV 5.220

130.2 0.05 0.05 15.5 7.6 126.97 -0.51 1.3 132.6

66.125 0.002 0.002 0.610 0.300 5.999 -0.020 0.063 DWV 6.220

155.6 0.05 0.05 15.5 7.6 152.37 -0.51 1.6 158.0

88.125 0.002 0.004 0.610 0.300 7.959 -0.020 0.083 DWV 8.220

206.4 0.05 0.10 15.5 7.6 202.16 -0.51 2.1 208.8

T

B

D

C

OD

Flare

A

BUILDING CONNECTIONS THAT LAST

17

TROUBLESHOOTING

TROUBLESHOOTING INSTRUCTIONS

Problem Possible Cause Solution

1. Pipe will not stay in grooving rolls.

Incorrect pipe positioning.

Improper grooving technique.

Power drive running counterclockwise

Model 3007.

See "Pipe Set-up & Positioning"

See "Grooving Pipe"

Ridgid 300 check setting in reverse

Clockwise rotation of pipe

2. Pipe stops rotating during grooving.

Rust or dirt has built up on lower roll.

Worn grooving rolls.

Ridgid 300 chuck jaws not engaged

properly.

Steel Pipe – Groove Diameter Stop

improperly adjusted.

Copper Tube – Groove Diameter Stop making

contact with top surface of Groover.

Remove accumulation from lower roll

with stiff wire brush.

Inspect lower rolls for worn knurls,

replace if worn.

See "Groover Set-up"

Adjust Groove Diameter Stop to

correct IPS.

Verify Groove Diameter Stop Nuts are

fully backed off.

3. Pipe flare excessive

Pipe stand adjusted too high.

Tool is tilted forward.

Incorrect pipe stand offset positioning. Pipe is

over "tracking".

Warped bottom roll shaft.

See "Pipe Set-up & Positioning"

See "Groover Set-up"

See "Pipe Set-up & Positioning"

Replace damaged bottom roll shaft.

The hinged collar may be missing.

Replace damaged parts.

4.While grooving loud squeaks echo

through the pipe or tube.

Pipe or Tube not square cut.

Incorrect pipe roller offset positioning.

Pipe is over "tracking".

Cut pipe or tube ends squarely.

Move pipe stand for proper offset.

See "Pipe Set-up & Positioning"

5.

During grooving loud thumps or bangs

occur about once every revolution of

the pipe.

Pipe has a pronounced weld seam. Grind welds flush with pipe surface inside

& out 2" back from pipe end.

6.Tool won't groove pipe.

Hand pump is low on oil.

Air in hydraulic system.

Pipe wall thickness exceeds tool's capability.

See "Groover Maintenance"

See "Groover Maintenance"

See "Groover Description"

1

2

3

4

5

6

About ASC Engineered Solutions

ASC Engineered Solutions is defined by quality—in its products, services and support.

With more than 1,400 employees, the company’s portfolio of precision-engineered

piping support, valves and connections provides products to more than 4,000

customers across industries, such as mechanical, industrial, fire protection, oil and

gas, and commercial and residential construction. Its portfolio of leading brands

includes ABZ Valve®, AFCON®, Anvil®, Anvil EPS, Anvil Services, Basic-PSA, Beck®,

Catawissa, Cooplet®, FlexHead®, FPPI®, Gruvlok®, J.B. Smith, Merit®, North Alabama

Pipe, Quadrant®, SCI®, Sharpe®, SlideLOK®, SPF®and SprinkFLEX®. With headquarters

in Commerce, CA, and Exeter, NH, ASC also has ISO 9001:2015 certified production

facilities in PA, TN, IL, TX, AL, LA, KS, and RI.

ASC-MAN-Gruvlok Roll Groover 3006/3006C Manual-v01 | 02.21

asc-es.com

This manual suits for next models

1

Table of contents

Other ASC Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Vega

Vega VEGABAR 12 operating instructions

RINGSPANN

RINGSPANN DV 020 FEM Installation and operating instructions

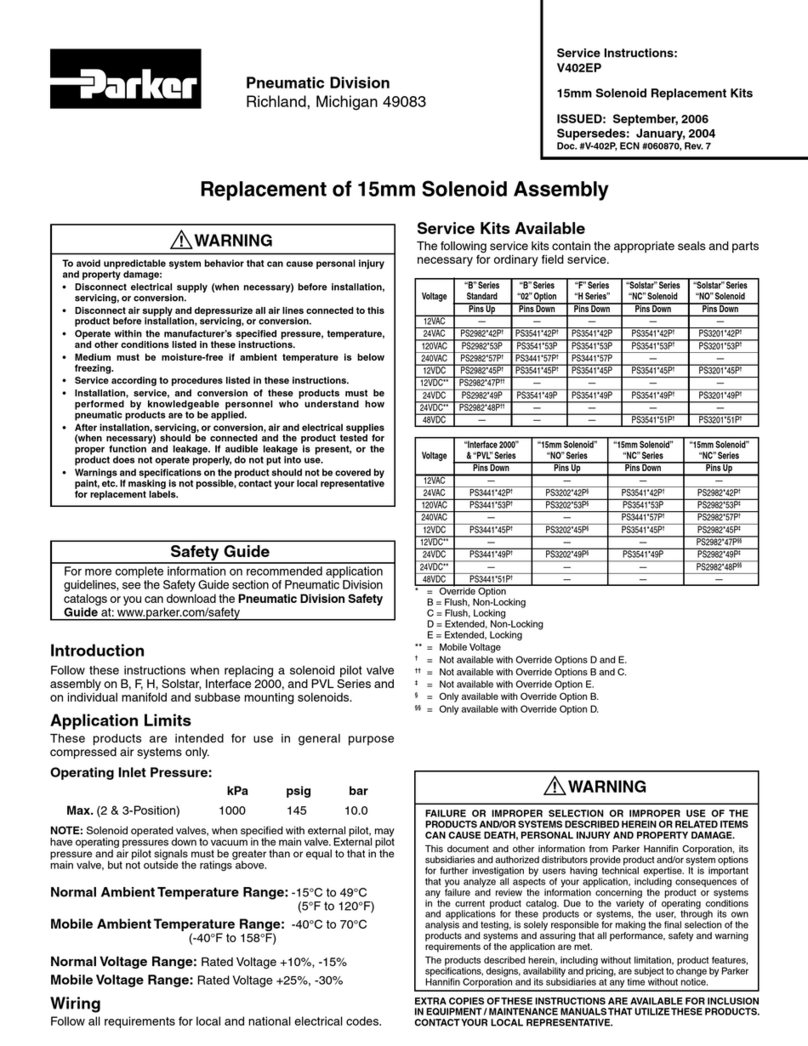

Parker

Parker V402EP Assembly

Beckhoff

Beckhoff TwinSAFE EJ19 Series operating instructions

Siemens

Siemens 3VL9100-4PA Series operating instructions

AxleTech

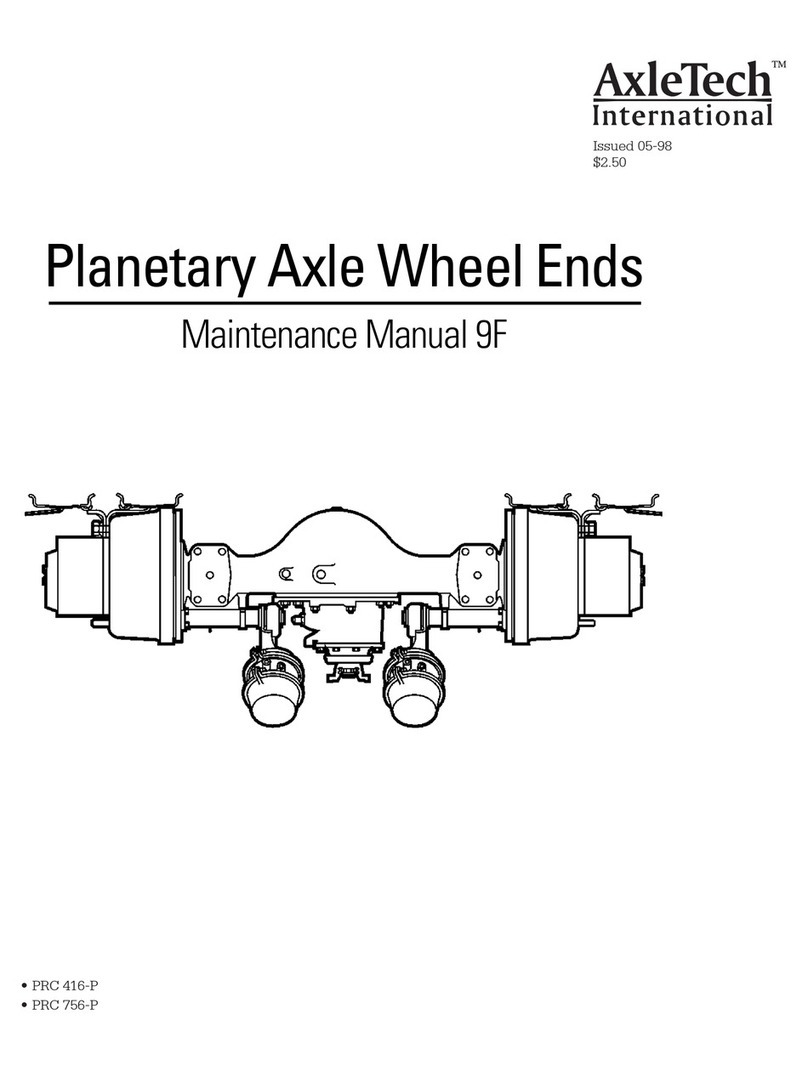

AxleTech PRC 416-P Maintenance manual