Manual, FT Sensor, Ethernet Axia

Document #9610-05-Ethernet Axia-05

Pinnacle

Park

•

1031

Goodworth

Drive

•

Apex,

NC

27539

•

T

el:+1

919.772.01

15

•

Fax:+1

919.772.8259

•

www.ati-ia.com • Email: [email protected]4

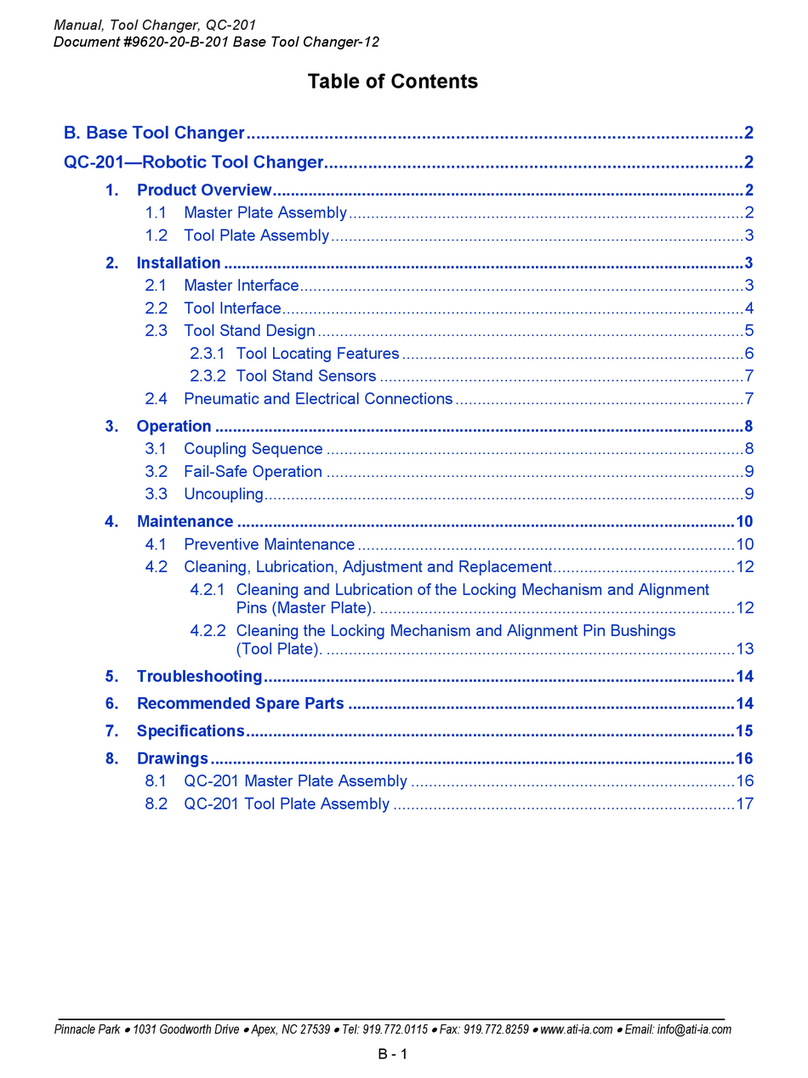

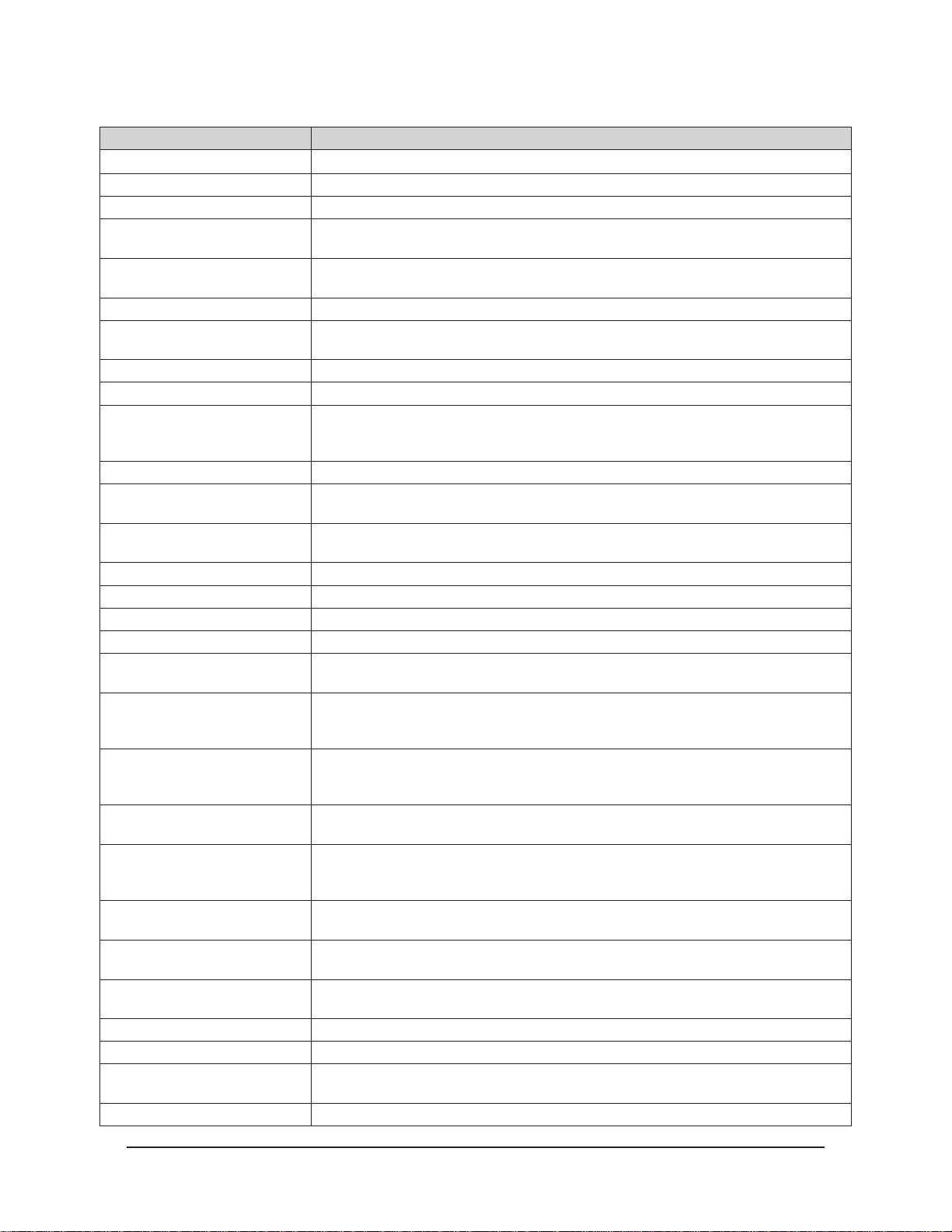

6. Java Demo Application.......................................................................................................... 31

6.1 Starting the Demo .......................................................................................................................31

6.2 Data Display with the Demo.......................................................................................................33

6.3 Collecting Data with the Demo...................................................................................................34

6.4 The Errors Display of the Demo.................................................................................................37

6.5 Developing Your Own Java Application....................................................................................37

7. Common Gateway Interface (CGI) ........................................................................................ 38

7.1 Settings CGI (setting.cgi) ...........................................................................................................39

7.2 CongurationsCGI(cong.cgi) .................................................................................................39

7.3 Communications CGI (comm.cgi)..............................................................................................40

8. System Settings XML Pages ................................................................................................. 41

8.1 SystemandCongurationInformation(netftapi2.xml) ...........................................................42

8.2 Calibration Information (netftcalapi.xml)..................................................................................43

9. UDP Interface Using RDT.......................................................................................................44

9.1 RDT Protocol ...............................................................................................................................44

9.2 Calculating F/T Values for RDT..................................................................................................46

9.3 Multiple Clients............................................................................................................................46

9.4 Notes on UDP and RDT Mode....................................................................................................46

9.5 Example Code..............................................................................................................................46

10. Operation ................................................................................................................................ 47

10.1 Sensor Environment...................................................................................................................47

10.2 LED Outputs ................................................................................................................................47

10.2.1 LED Self-Test Sequence..................................................................................................47

10.2.2 L/A LED ............................................................................................................................47

10.2.3 DIAG LED.........................................................................................................................47

10.2.4 Sensor Status LED...........................................................................................................48

10.3 Sample Rate.................................................................................................................................48

10.3.1 Sample Rate Versus Data Rate .......................................................................................48

10.4 Low-Pass Filter............................................................................................................................49

10.5 Console Commands....................................................................................................................52

10.6 System and Calibration ..............................................................................................................52

10.7 Status Code .................................................................................................................................54

10.7.1 Status Code: Sensing Range Exceeded..........................................................................55

10.8 Diagnostic Monitoring ................................................................................................................56