Operating Instructionsl Ascoline 700, AEF12x, 14x, 22x

ascobloc Gastro-Gerätebau GmbH 01156-Dresden, Grüner Weg 29 Germany

Tel.:

(0351)

4533-0

Fax

(0351)

4537-339

E-mail:

[email protected], BA-AEF_e.doc, Stand: 18/.1.2012 We reserve the rights to change specifications!

3

Do not raise or move the appliance using the top plate, the lower edges on the side or the door handle.

Use the lower edge at the front or at the back instead.

3.5 Advice on installation

The appliance is wired up to the connection box. To ensure the safety of our products it is necessary that

every connection process is carried out by an expert. Please allow these experts to look at these

documents. The statutory regulations (Germany VDE, Austria ÖVE, Switzerland SEV etc.) as well as the

connection conditions of the local electricity supply company must be observed completely.

Before beginning the installation work, it should be checked that the mains voltage, mains type and the

current rating of the fuse match the values given on the type plates. An isolating device in the customer's

scope of supply that is effective on all poles must be provided, e.g. contactor fuses with at least 3 mm

contact gaps, so that the equipment is disconnected from the power supply during repair and installation

work. Connection to an equipotential bonding system is available (check effectiveness).

Do not bend, squash or damage cables (according to EN 60335-2-50) on any sharp edges. Lay the cables

in such a way that they cannot be brought into contact with hot parts. The connection cable leading

through the appliance must be fully sheathed from the connection point up to the entrance to the terminal

box. The appliance is intended for fixed connection; it is not permitted to connect the appliance using

plugs.

4. Installation

4.1 Location

Do not install the appliance next to walls, kitchen furniture, decorations or other inflammable materials.

Nonobservance causes fire danger!!! For the minimum distance please refer to the wiring diagram and

product description. Pay attention to the local fire protection regulations!

The appliance must be levelled out by using a spirit level. Otherwise the drawers and doors will not work

and shut perfectly. Appliances with height-adjustable feet can level the uneven floor slightly (+/- 20 mm)

by turning the feet. In case of installation on a plinth the appliance may be levelled by an appropriate

underlay.

Do not place the Deep Fat Fryers close to any kind of fluid or water containing appliances, e.g. bain-marie

or boiling pan.

This demand can be disregarded in case the following conditions between Deep Fat Fryer and any

appliances containing fluid are achieved:

•a gap of at least 900 mm

or FIRE!!!

•a 350 mm high and fire-proof partition

•Water out of a sprinkler system must not get in contact with hot fat.

4.1.1 Free-standing appliance

For installation as a free-standing appliance, it must be attached in a suitable way to prevent the appliance

from tipping over or moving.

4.1.2 Installation in groups or blocks

For installation in groups or blocks the appliances must be connected with each other by using suitable

connection elements. This is in interest of hygiene. Furthermore, take note of the respective instructions in

the appliances’ leaflet, brochure or installation diagram. If the appliance is fitted into kitchens of other

manufacturers refer to the corresponding brochures of the manufacturer for the necessary accessories.

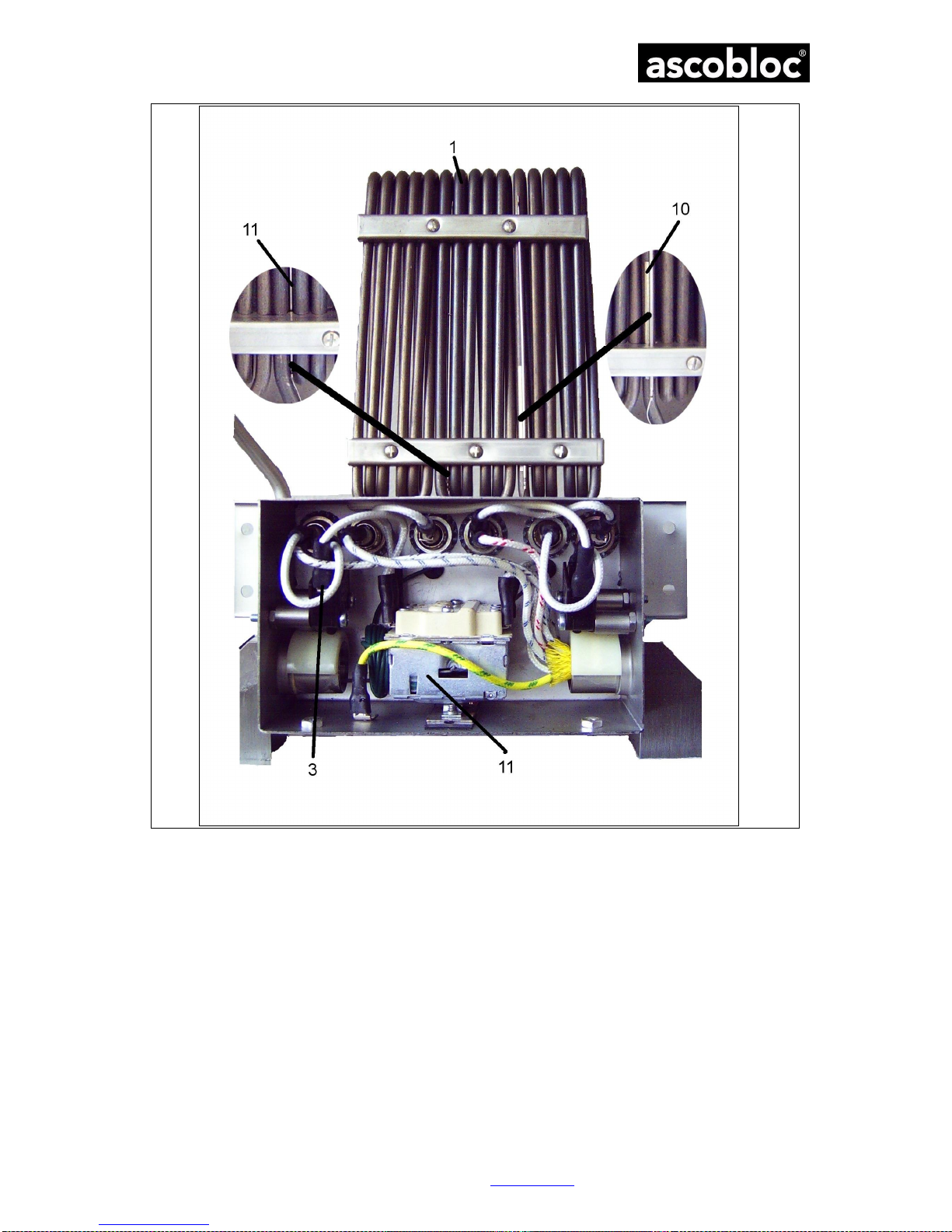

4.2 Connections

Refer to details about connections in the enclosed wiring diagram and in the description of the appliance.

Please check whether the dimensions and the position of the electric outlet correspond to the

specifications in the appliances’ leaflet, brochure or installation diagram.

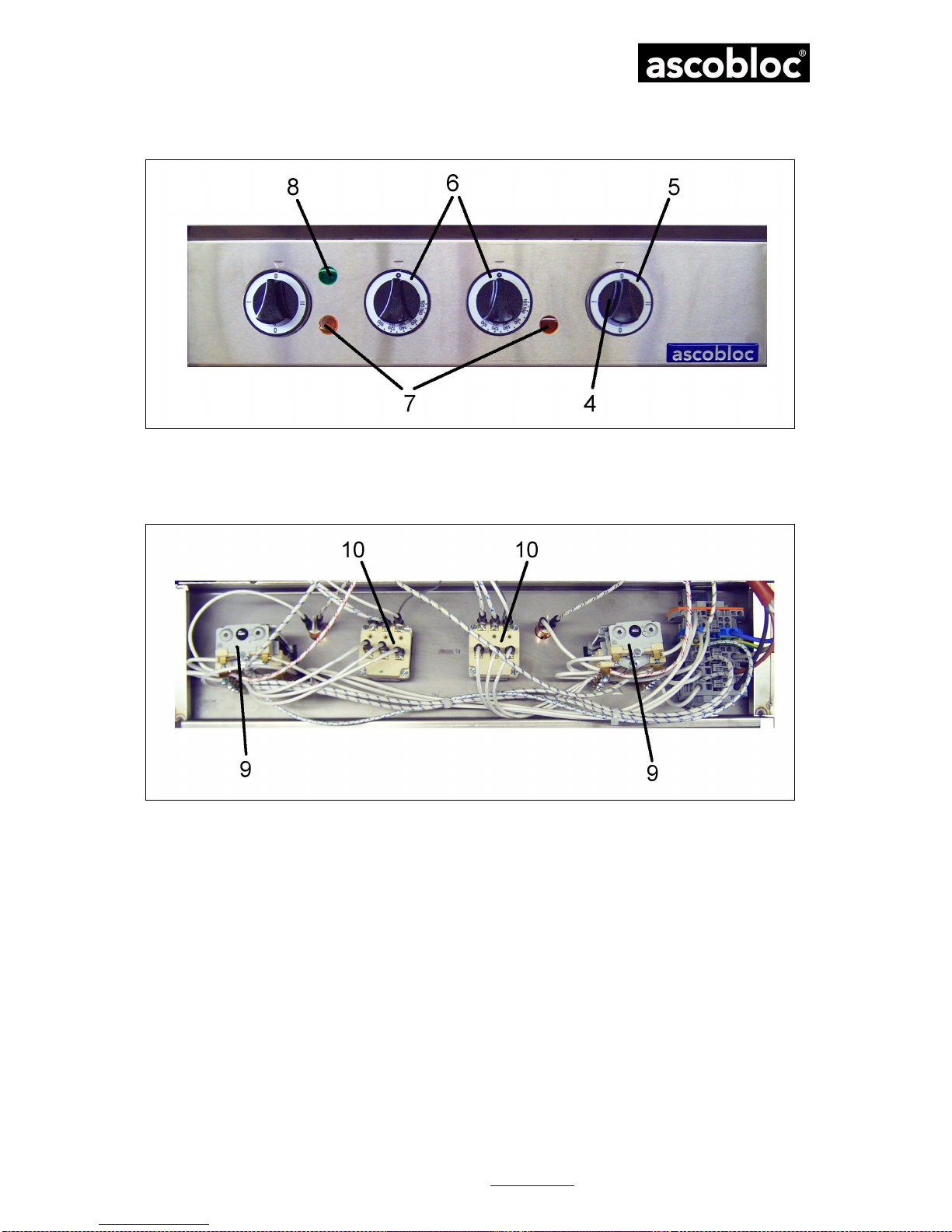

The terminal box is located behind the front panel A. Please make the connections according to the valid

wiring diagram. The number of the applicable wiring diagram is on the appliance identification plate.

After completing all installation work mount all covers and panels and screw them tight.

4.2.1 Free-standing appliance

Connections can be made underneath or at the back of the appliance. For connection underneath a gap

of at least 50 mm towards the footprint is needed.

4.2.2 Wall and table top appliance, connection to an installation wall or wall-mounted frame

When mounting the appliance to an installation wall or a wall-mounted frame (ACC 881), connections

underneath or at the back of the appliance should be used.