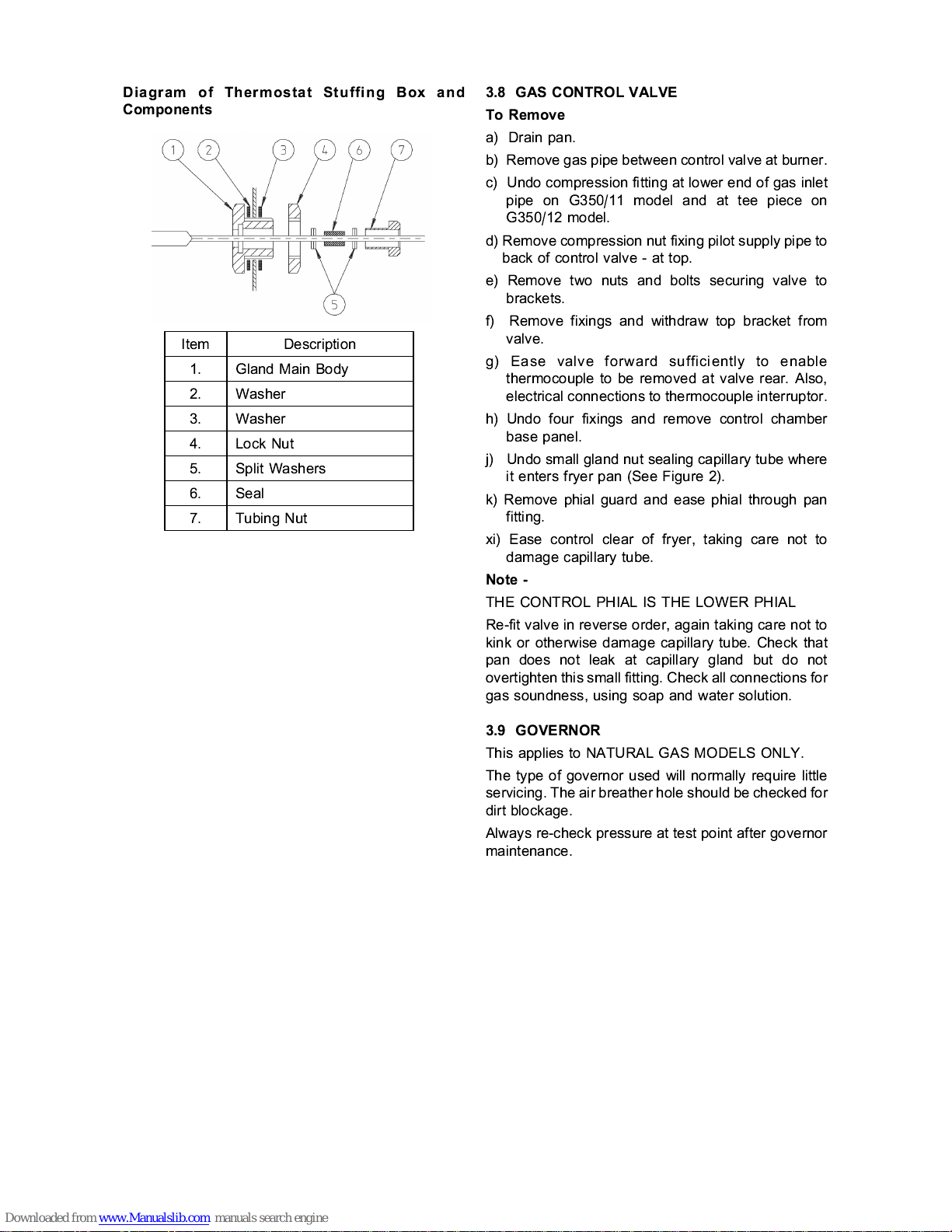

Replace parts in reverse rder. Take care n t t ver

tighten gland nut t av id p ssibility f cracking

ceramic material. The spark gap is pre-determined

and cann t be adjusted. D n t attempt t alter gap

by bending electr de.

3.7 HIGH TEMPERATURE LIMIT DEVICE

This is an electrical therm stat which interrupts

therm c uple circuit. In event f failure f c ntr l

therm stat (emb died in gas c ntr l valve), the high

temperature limit device will sense excessive il

temperature and pen - thus all wing gas valve in

c ntr l t cl se.

Once triggered, high temperature limit device must be

manually re-set by pressing red butt n n

therm stat b dy.

To Remove

a) Drain pan.

b) Rem ve fr nt facia panel by rem ving fixings in

panel underside.

c) Pull ff electrical c nnecti ns fr m interrupter

situated at gas c ntr l valve rear and release

electrical leads.

d) Und f ur fixings and rem ve c ntr l chamber

base panel.

e) Und gland nut sealing capillary tube where it

enters pan.

Note

THE SAFETY PHIAL IS THE UPPER PHIAL

f) Fr m inside pan, release therm stat phial fr m

m unting bracket by m ving it slightly t ward rear

f pan and then upward.

g) Ease phial and capillary tube thr ugh pan fitting.

h) Rem ve tw fixings that secure therm stat t

bracket and rem ve c mplete unit fr m fryer.

Replace in reverse rder, taking care n t t damage

capillary tube. Thereafter -

j) Press red butt n t ensure c ntacts are cl sed

bef re lighting fryer.

k) Fill pan with il t level mark.

m) Check sealing gland d es n t leak but d n t

vertighten gland nut.

n) Heat pan at maximum temperature setting and

all w c ntr l therm stat t cycle nce r twice t

ensure that high temperature limit device d es n t

trigger prematurely.

Operati n f safety therm stat must be checked at

regular intervals. In rder t raise il temperature

sufficiently t enable safety therm stat t perate,

it will be necessary t rem ve sens r bulb f c ntr l

therm stat fr m il. This c nditi n can be

acc mplished by the f ll wing pr cedure:

a) Drain pan.

b) Rem ve upper panel ab ve d r by rem ving

fixings in panel underside.

c) Und fixings and rem ve c ntr ls chamber base

panel.

d) Slacken small gland nut sealing capillary tube

where it enters fryer pan (See Figure 2).

Note

THE CONTROL PHIAL IS THE LOWER PHIAL

e) Rem ve phial guard and ease c ntr l therm stat

sens r t wards pan rear t clear l cating brackets.

Draw capillary tube thr ugh glands t enable

sens r t be suspended ut f the il when pan is

t be re-filled t marked level.

f) Tighten small gland nut t temp rarily c mpress

seal n t capillary tube.

g) Temp rarily refit phial guard ver high limit device

sens r.

h) Refill pan with il t marked level.

j) Install a means f measuring il temperature.

A therm c uple-type instrument is preferable but

a mercury therm meter capable f measuring up

t 300

C can be used. The measuring sens r,

i.e. therm c uple r therm meter bulb must be

suspended 25mm bel w il surface in pan centre.

k) Light fryer and carefully bserve rising il

temperature. The safety therm stat, if functi ning

pr perly, will shut- ff gas when il temperature is

between 218

C and 224

C (maximum).

m) If safety therm stat fails t perate at maximum f

224

C, shut ff fryer immediately by pressing " ff"

butt n n gas c ntr l valve (see Secti n 2.5,

Figure 1). All w il t c l bef re investigating

fault.

n) All safety therm stats are accurately calibrated

and checked n new appliances during

manufacture. It is unlikely that calibrati n will need

service adjustment assuming therm stat is n t

therwise faulty.

p) Once satisfied that safety therm stat is functi ning

c rrectly, c ntr l therm stat sens r must be

re-l cated in n rmal p siti n. A reversal f

pr cedures (a) t (h) will achieve this c nditi n.

Note

Replace seal n c ntr l therm stat gland and ensure

that n il leaks are present.