WARNINGS

1. Use a qualified technician to maintain the jack in good condition. Keep it clean for best and safest

performance.

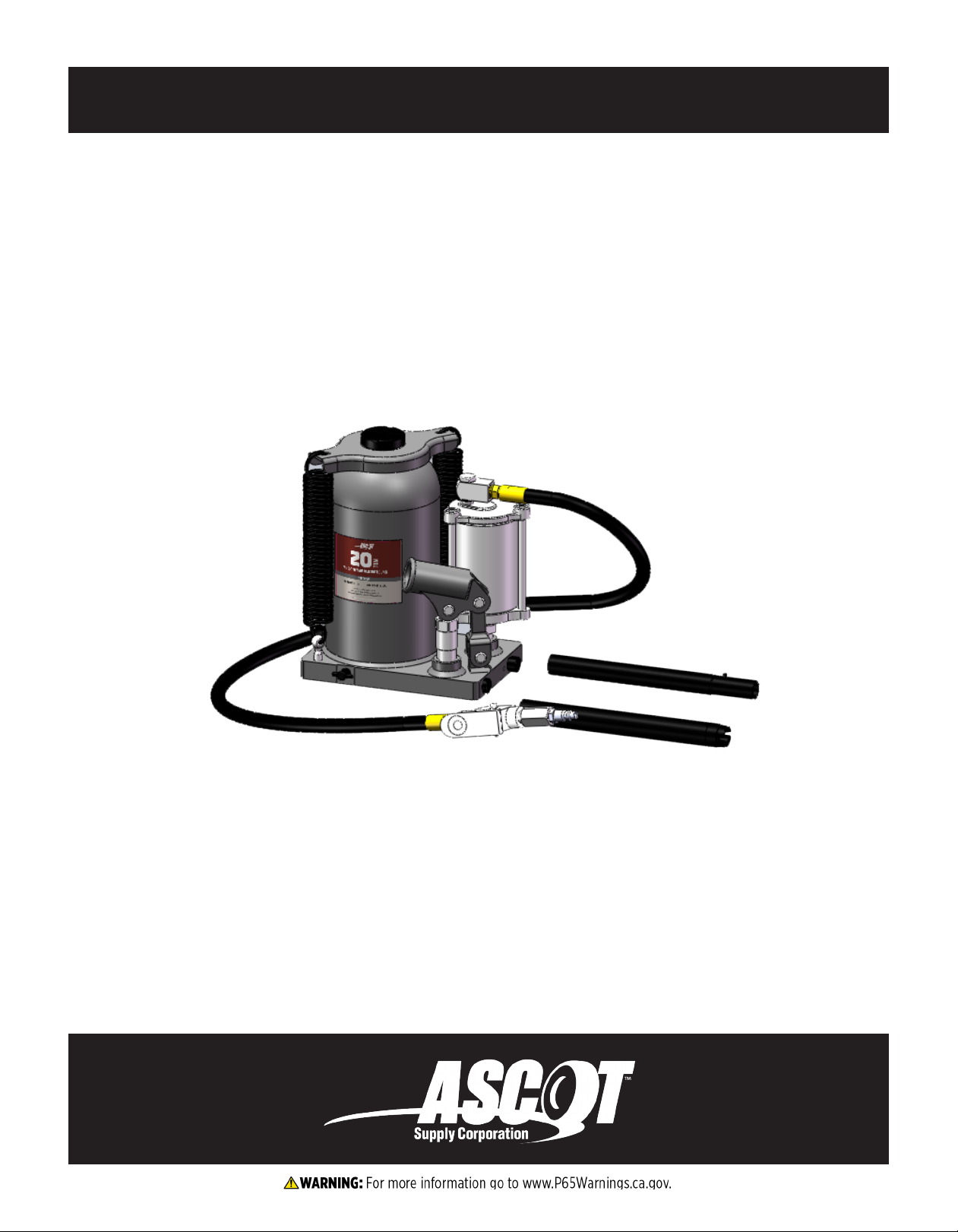

2. The maximum load is 20 tons. DO NOT exceed this rated capacity.

3. Use this jack for lifting purpose only. DO NOT use it for any other purpose it is not designed to perform.

4. Keep children and unauthorized persons away from the work area.

5. Remove ill fitting clothing. Remove ties, watches, rings and other loose jewelry and contain long hair.

6. Wear ANSI approved safety goggles when operating the jack.

7. Keep proper balance and footing, do not overreach. Wear nonslip footwear.

8. Only use this jack on a surface that is stable, level, dry, not slippery, and capable of sustaining the

load. Keep the surface clean, tidy and free from unrelated materials and ensure that there is adequate

lighting.

9. When lifting a vehicle, apply the emergency brake and block all wheels.

10. Immediately after lifting, support the load with appropriate supporting equipments such as jack stands

of adequate capacity! DO NOT work under a load which is supported only by a jack.

11. Before lowering load, ensure that there are no obstructions underneath and that all persons are standing

clear.

12. DO NOT attempt to move the load while on the jack. The jack must only be used in a static position for

lifting and lowering loads. Ensure that the load remains stable at all times.

13. DO NOT use the jack if damaged, if any suspect parts are noted or it has been subjected to a shock load.

14. DO NOT operate the jack when you are tired or under the influence of alcohol, drugs or any intoxicating

medication.

15. DO NOT allow untrained persons to operate the jack.

16. DO NOT make any modifications to the jack.

17. DO NOT use brake fluid or any other improper fluid and avoid mixing different types of oil when adding

hydraulic oil. Only a good quality hydraulic jack oil should be used.

18. DO NOT expose the jack to rain or any other kind of inclimate weather.

19. If the jack needs repairing or there are any parts that need to be replaced, have it repaired by

authorized technicians and only use the replacement parts supplied by the manufacturer.

20. WARNING: The warnings, cautions and instructions discussed in this instruction manual cannot cover

all possible conditions and situations that may occur.

2