WARNINGS

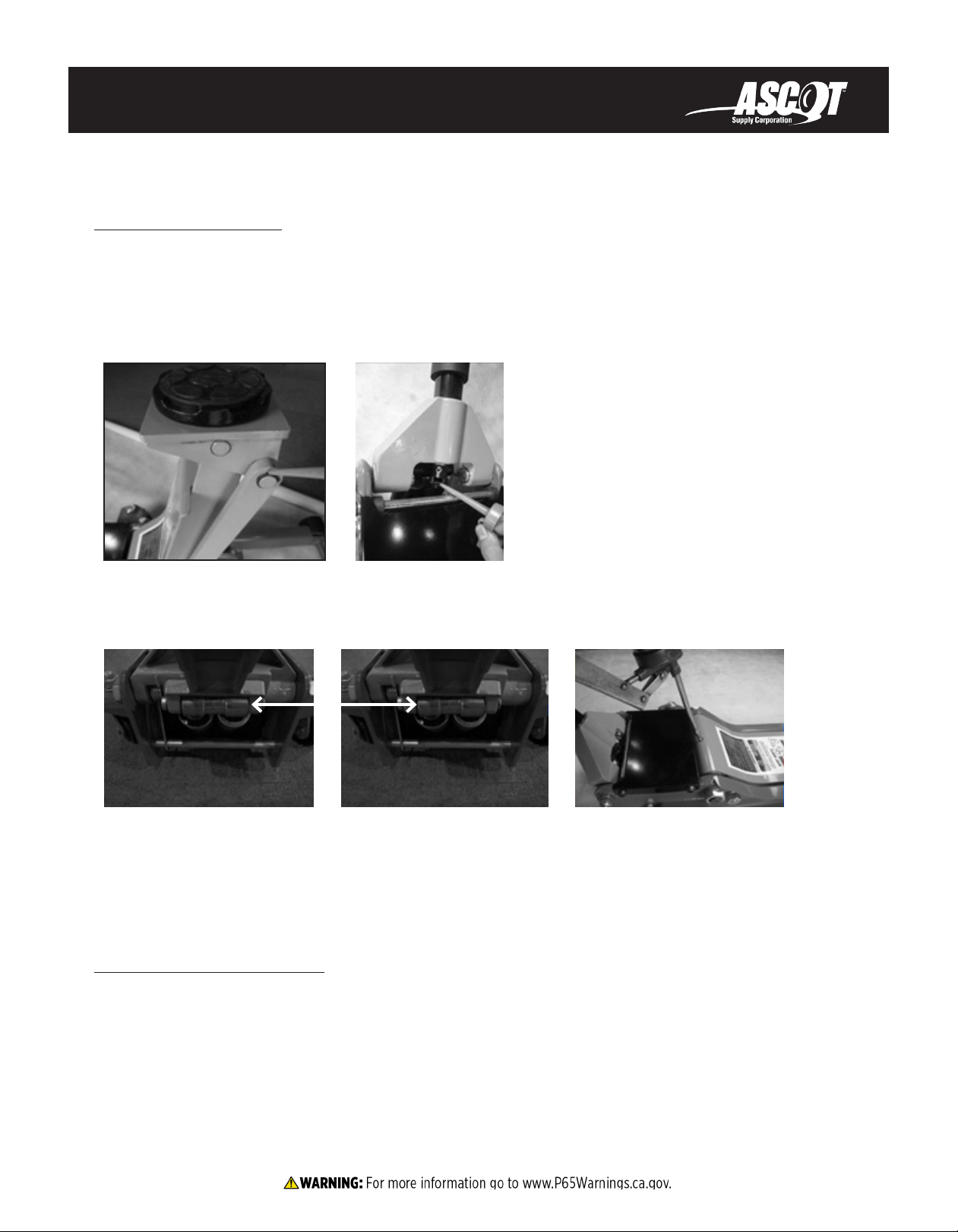

1) Locate the jack in a suitable working area.

2) Inspect the jack before each use. Do not use jack if damaged, altered, modified, in poor condition, leaking

hydraulic fluid or unstable due to loose or missing hardware or parts. Make corrections before using.

3) Use jack on level and solid ground, preferably concrete. Avoid tar macadam as jack may sink in. Chock

wheels of vehicle.

4) Ensure the vehicle’s parking brake is engaged, engine is switched off and transmission is in gear (or

“PARK” if automatic).

5) Ensure minimum distance of 2 feet between vehicle and static objects such as doors, walls, etc. to allow

for vehicle tilting.

6) Ensure all non-essential persons keep a safe distance while the jack is in use.

7) Ensure there are no passengers in the vehicle.

8) Place jack under only those lifting points recommended by vehicle manufacturer (see vehicle’s owner’s

manual).

9) Check that the lifting point is stable and centered on the jack saddle.

10) Ensure the jack wheels are free to move and that there are no obstructions.

Danger: Use the jack for lifting only!

11) Ensure there are no persons or obstructions beneath the vehicle before lowering.

12) Use a pair of suitable axle stands under the vehicle before proceeding with any task.

13) Use a qualified person to lubricate and maintain the jack.

14) Wear ANSI-approved safety goggles and heavy duty work gloves during use.

15) Ensure that only hydraulic jack oil is used in the jack.

DO NOT operate the jack if damaged.

DO NOT allow untrained persons to operate the jack.

DO NOT exceed the rated capacity of the jack.

DO NOT allow the vehicle to move during lifting or lowering, or use the jack to move the vehicle.

DO NOT jack vehicle if there is a risk of spillage of fuel, battery acid or other dangerous substances.

DO NOT work under the vehicle until appropriately rated axle stands have been correctly positioned.

DO NOT fill hydraulic system with brake fluid, alcohol or transmission oil. Use hydraulic jack oil only.

DO NOT adjust the safety overload valve.

DO NOT use for aircraft purposes.

16) When not in use store jack, fully lowered, in a safe, dry, childproof location.

17) The warnings, precautions and instructions discussed in this manual cannot cover all possible conditions

and situations that may occur.

2