Page6

WARNING!

Before working on wiring for any

electrical appliance, be sure the electrical power

has been turned off at the breaker/fuse box.

WARNING!

Disconnect electrical power

supply and place a tag at the disconnect switch

indicating that you are working on the circuit.

WARNING!

Electrical and grounding

connections must comply with the applicable

portions of the national electrical code and/or

other local electrical codes.

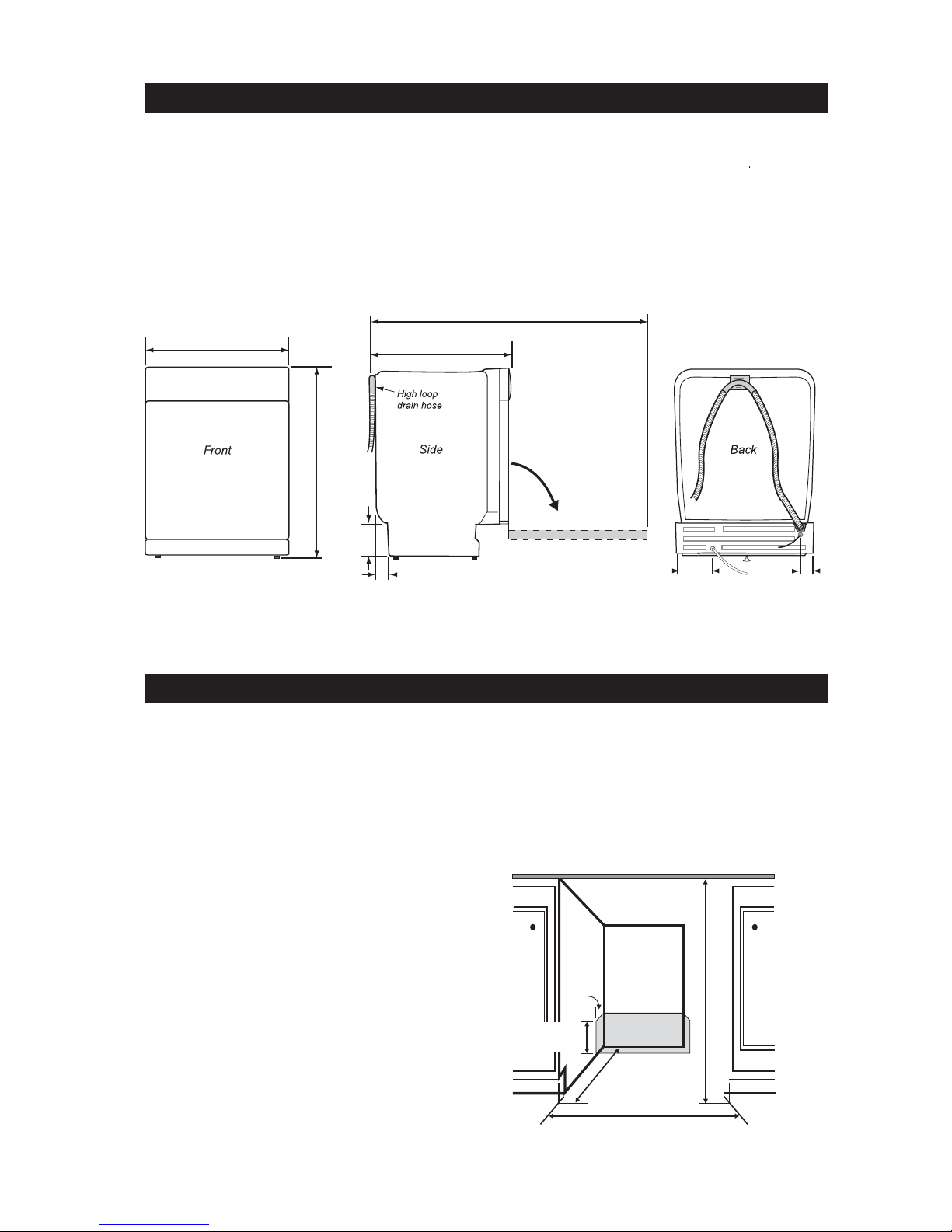

This unit must be grounded to operate properly. It must

be connected to a grounded metal, permanent wiring

system, or an equipment-grounding conductor must

be run with the circuit conductors and connected to the

equipment-grounding terminal or lead of the appliance.

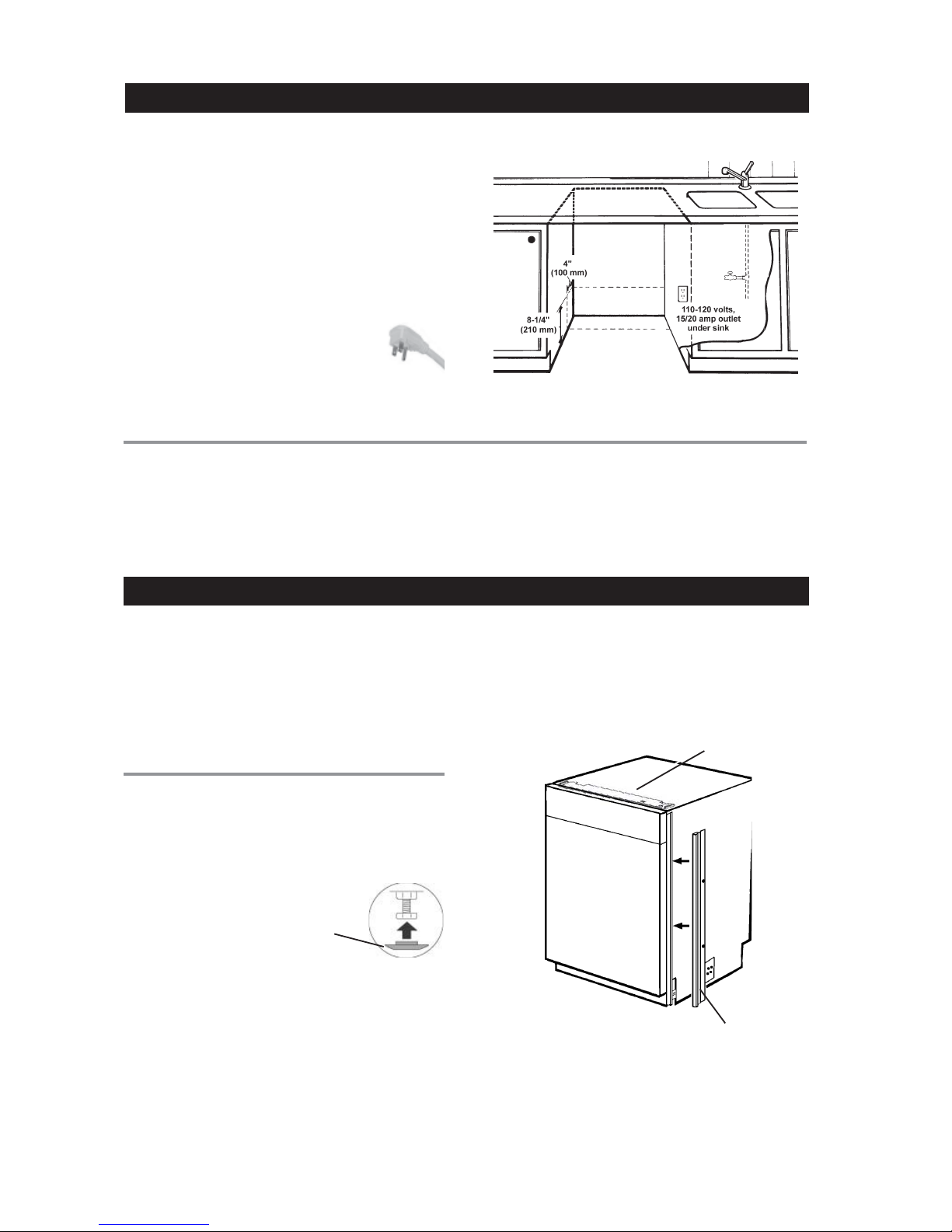

NOTE: Access holes should be 1-1/2” to 2” (38 mm

to 50 mm) in diameter with no sharp edges.

The dishwasher comes with an electrical

cord for 110-120 volts, 15/20 amp

supplied. This cord should be plugged into

the 110-120 volt outlet under the sink.

If the cord is not long enough, or if a hard-

wire installation is needed, follow

instructions on page 8.

GRGR

GRGR

GROUNDING INSTROUNDING INSTR

OUNDING INSTROUNDING INSTR

OUNDING INSTRUCTIONSUCTIONS

UCTIONSUCTIONS

UCTIONS Damage to the dishwasher could occur if it is not

properly grounded.

WARNING!

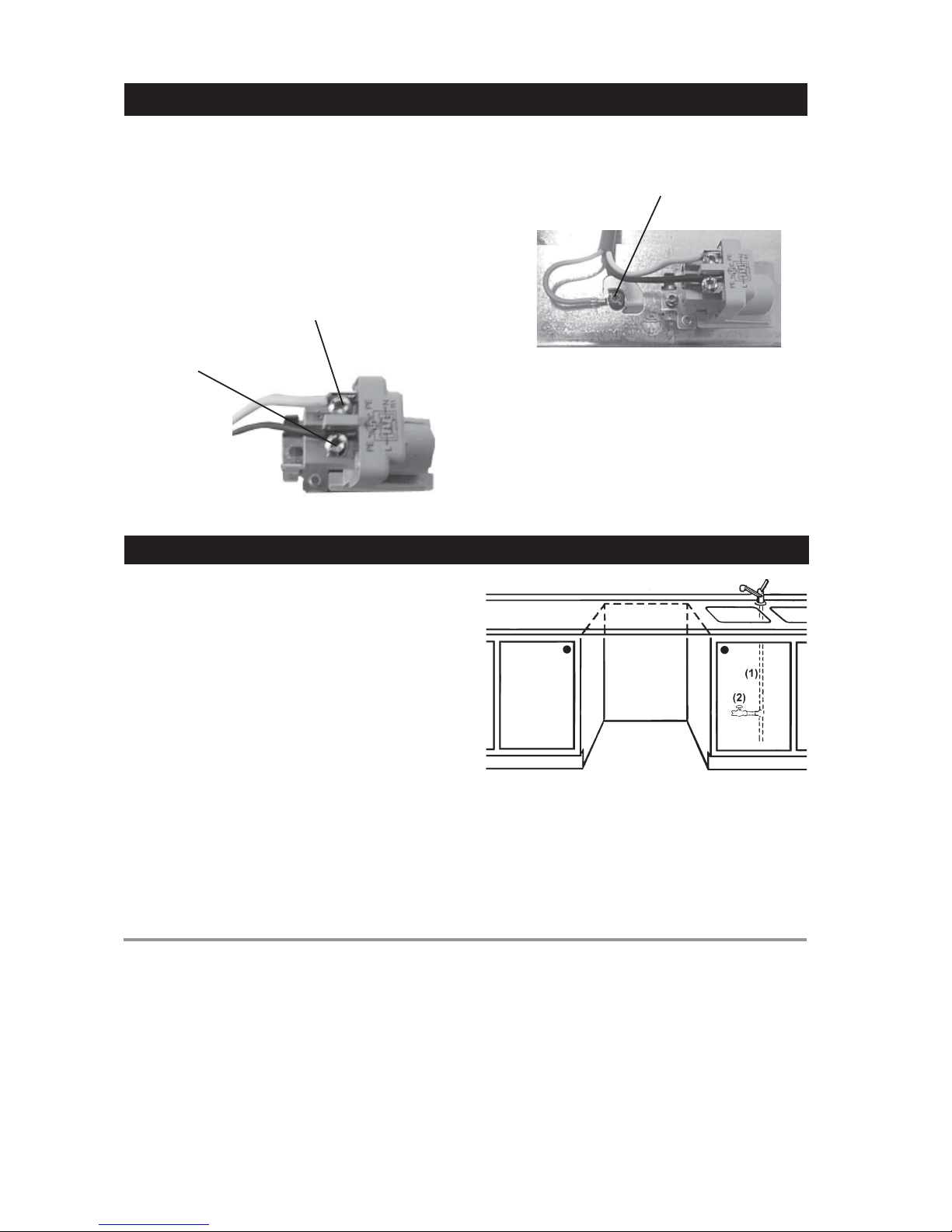

Make sure the water supply line,

drain line and branch circuit wiring do not touch

any exposed terminals of dishwasher wiring.

At this point the styrofoam, plastic wrap, and the wood

pallet (base) should be removed from the dishwasher.

Now is an excellent time to inspect for any shipping

damage. Should you find any damage, you should

report it to your dealer or builder immediately.

Be sure to remove the toe kick and toe kick insulation

which are on top of the dishwasher.

SLIDES FOR LEGSSLIDES FOR LEGS

SLIDES FOR LEGSSLIDES FOR LEGS

SLIDES FOR LEGS

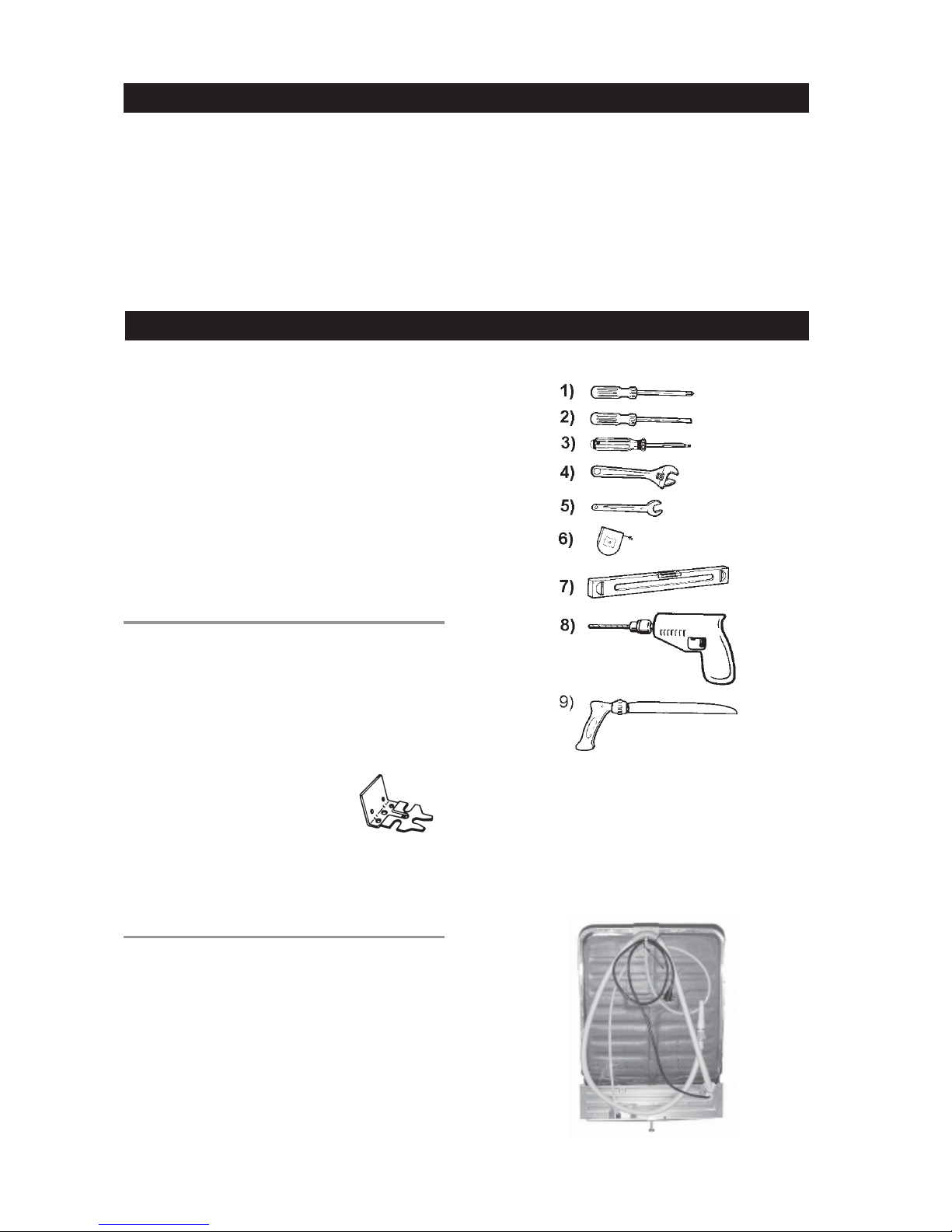

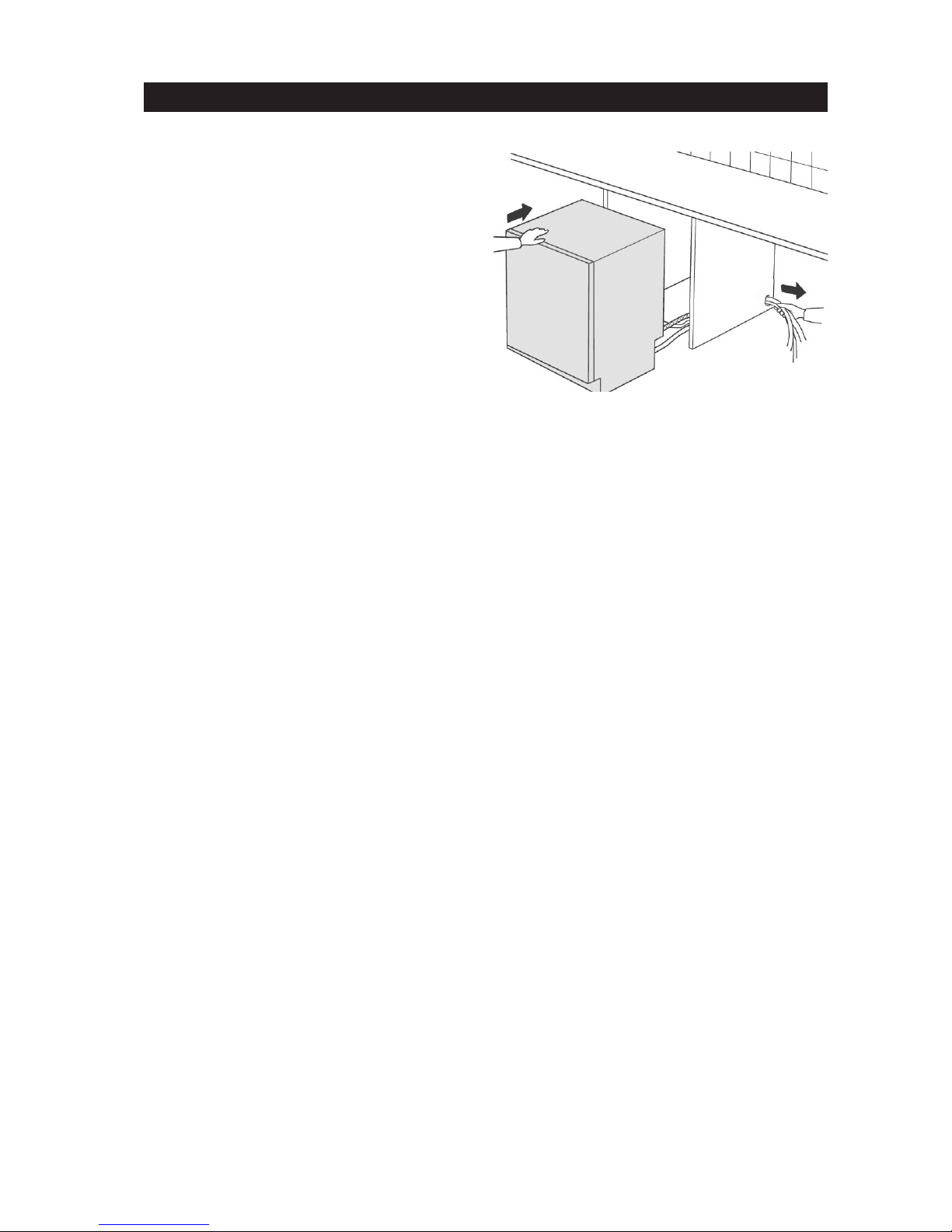

The unit comes with white plastic slides for the legs to

protect the kitchen floor from being damaged when you

slide the unit into place. The slides simply snap onto

the bottom of the legs.

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

PREPPREP

PREPPREP

PREPARINGARING

ARINGARING

ARING THE DISHWTHE DISHW

THE DISHWTHE DISHW

THE DISHWASHER FOR INSTASHER FOR INST

ASHER FOR INSTASHER FOR INST

ASHER FOR INSTALLAALLA

ALLAALLA

ALLATIONTION

TIONTION

TION

WARNING!

Do not use an extension cord for this appliance.

THE FILL STRIPSTHE FILL STRIPS

THE FILL STRIPSTHE FILL STRIPS

THE FILL STRIPS

All Asko Tall Tank dishwashers come with color-coded

fill strips to finish out the installation.

Fill Strip

NOTE: If the cabinet opening is European measure-

ment (23-1/2 inches [597 mm]), remove the fill

strips to fit the dishwasher into the opening.

Protective slides for legs simply

snap onto the bottom of the legs.

Fill Strip

(Noton allmodels)