10

COMPONENT INFORMATION

Flow meter

The flow meter is fitted in the air gap. The

flow meter is used to control the water intake

so that the right volume is taken in regard-

less of the water pressure. It is even possible

to program the machine for time-controlled

water intake.

The flow meter comprises an impeller with two

magnets that is driven by the water flow. On the

outside, on the flow meter housing, is a sensor,

a reed switch, which closes each time the mag-

nets pass. The number of pulses from the sensor

is proportional to the volume of the flowing

water. A minimum water flow of 2 litres/minute

is required for the flow meter to operate. If

the necessary level is not reached within one

minute, the program stops.

Output signal: 220 pulses per litre.

Circulation pump

The circulation pump comprises an asynchro-

nous motor, with a pump component and a

condenser.

Spray arm diverter

Certain machines are fitted with a spray arm

diverter. The spray arm diverter comprises a

synchronous motor that drives a disc valve

via a gearbox. The disc distributes different

4.2Componentsandfunctiondescription

Here we present the functions and specifica-

tions of the various electrical components.

Some components are only found in high-end

machines or in particular markets.

Inlet valve

Both single and safety inlet valves are used.

The valve contains a filter to stop particles then

a flow limiter to limit the flow to a maximum of

4 l/min. The valve opens when the water pres-

sure exceeds 0.3 bar and provides full flow at

about 2 bar.

Safety valve

The safety valve has two independent valve

seats, each controlled by a separate elec-

tromagnet. The valve seats are connected

in series. This doubles the safety factor. The

electromagnets are also connected in series

(electrically), which means each magnet’s

rated voltage is half the mains voltage (e.g., a

230 V valve = 2 x 115 V coils)

Single valve

The single valve comprises an electromagnet

and a valve seat.

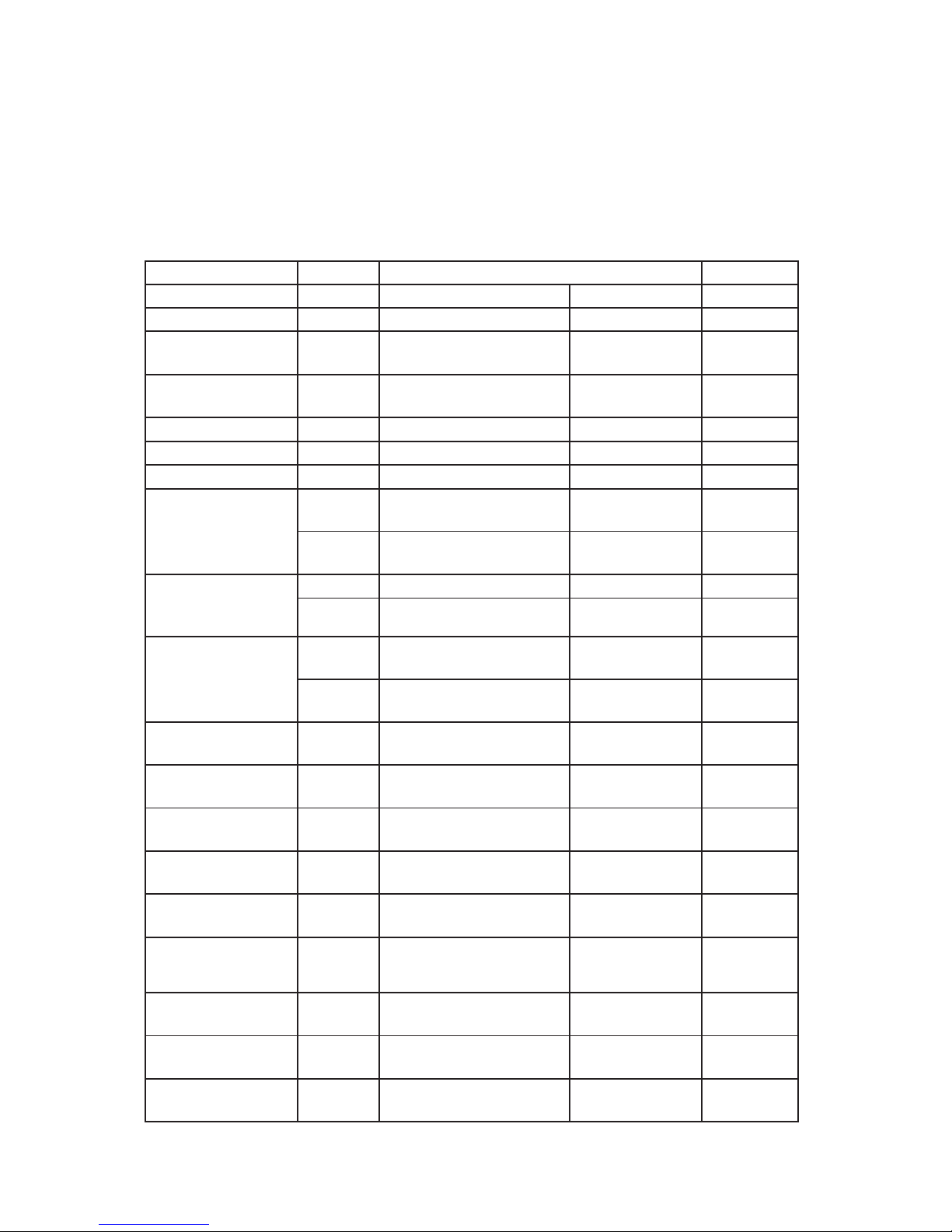

Article no. Position Component

8078090*

8078090 *

Softener salt water

valve 220/240 V

3 kohm

Softener mixer valve

220/240 V

2.33 kohm

8078302*

8078302*

Softener salt water

valve 120 V

0.65 kohm

Softener mixer valve

120 V

0.65 kohm

8073830 Halogen bulb 5 W/12 V <10 kohm

8052778 Vax motor 1.1 kohm

8073850 Fan motor 230 V 0,44 kohm

8073848 Fan motor 120 V 0.18 kohm

* The number is for a complete water softener; replacement salt and mixer valves are not

available separately.