Contents

❏What is a Dryer?......................................................................................................................................................2

❏ Dryer Specication..................................................................................................................................................4

❏ Operating Mechanism Diagram (Gas Type) ..........................................................................................................5

❏ Operating Mechanism Diagram (Electric Type)......................................................................................................6

❏ Mechanism by Ass’y (Electric Type).......................................................................................................................7

❏ Mechanism by Ass’y (Gas Type)............................................................................................................................8

❏ Parts List by Ass’y...................................................................................................................................................9

❏ PCB Function Specication ..................................................................................................................................23

❏ Drum Dryer Troubleshooter ..................................................................................................................................37

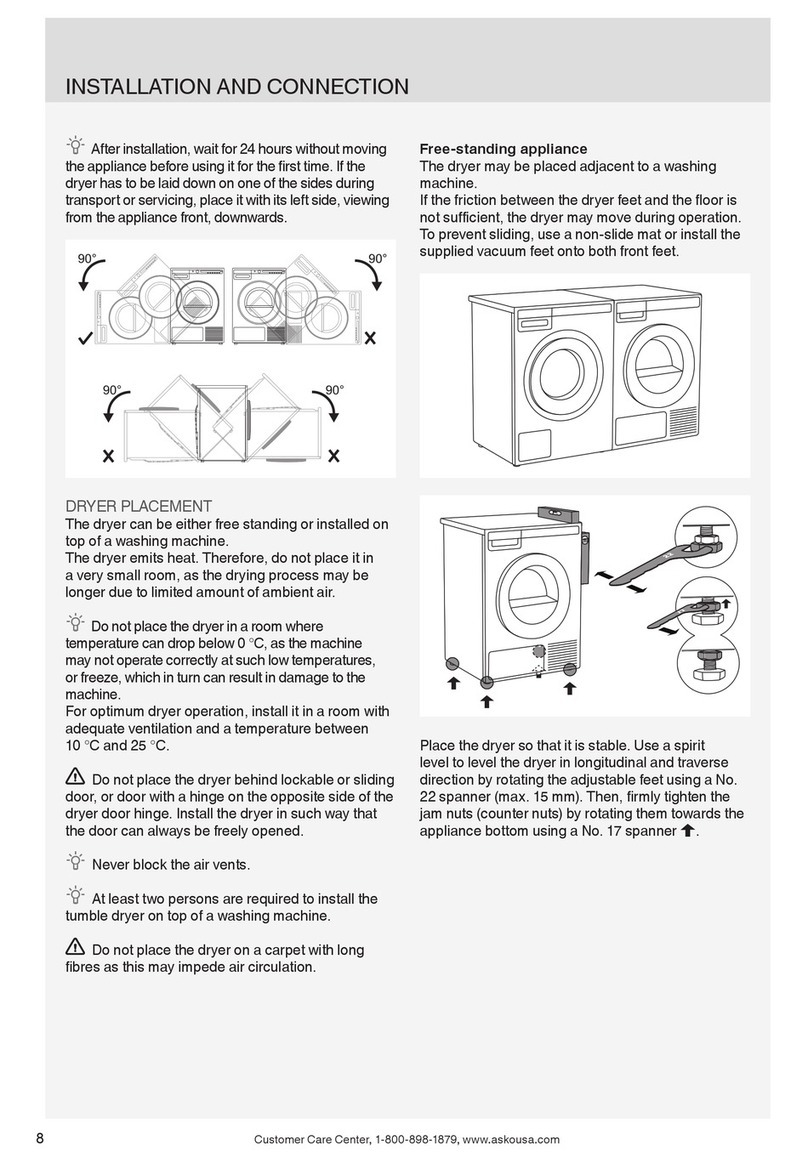

❏ Dryer Installation ...................................................................................................................................................40

❏ Electrical Requirements For Electric Dryers.........................................................................................................41

❏ Dryer Service Notices ...........................................................................................................................................47

❏ Electric Parts List - Electric Clothes Dryer ............................................................................................................48

❏ Electric Parts List - Gas Clothes Dryer .................................................................................................................49

Thermostat Fan..................................................................................................................................................................50

Thermostat Cut-Out ...........................................................................................................................................................51

Thermostat Hi-Limit............................................................................................................................................................52

Lamp Assembly ................................................................................................................................................................53

Switch Door........................................................................................................................................................................54

Heater Assembly................................................................................................................................................................55

Belt Switch (Switch Micro) ................................................................................................................................................56

Thermistor Fan...................................................................................................................................................................57

Motor Dryer ........................................................................................................................................................................58

Igniter As ............................................................................................................................................................................60

Flame Senso......................................................................................................................................................................61

Thermostat Hi-Limit............................................................................................................................................................62

Thermostat Cut-Out ...........................................................................................................................................................63

Valve Gas As .....................................................................................................................................................................64

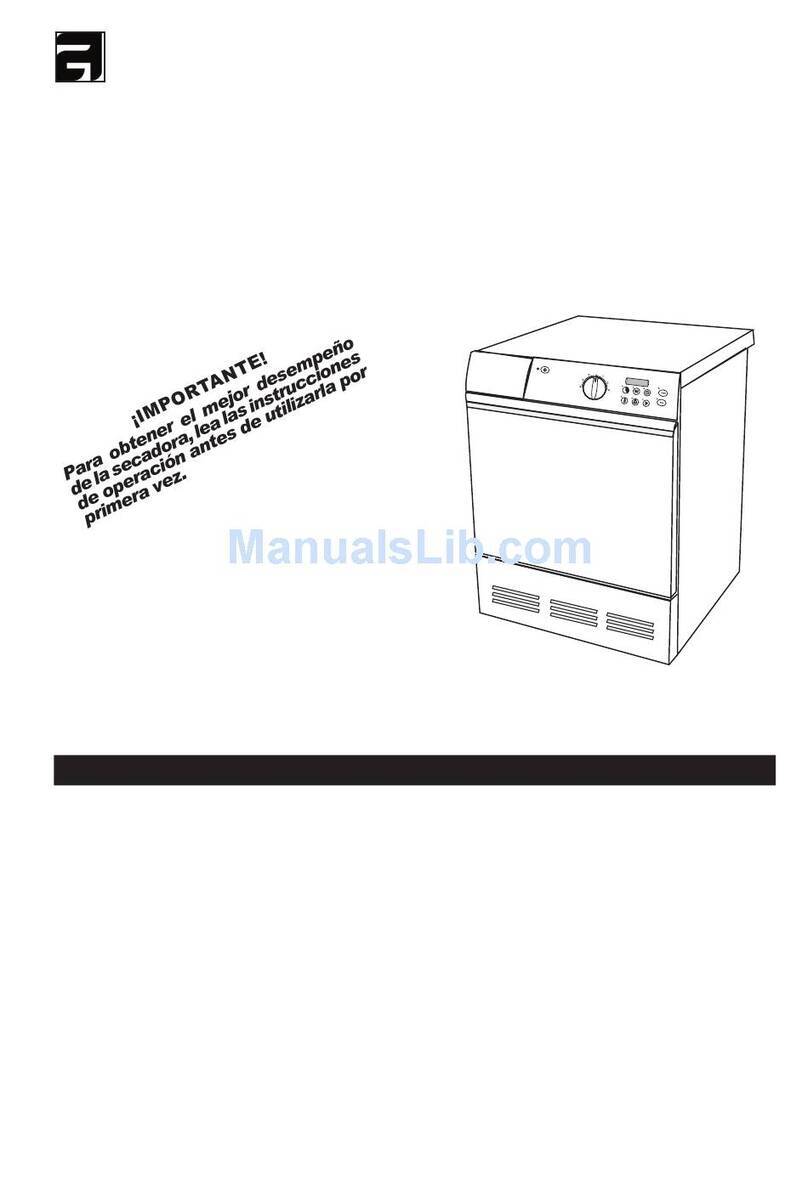

❏ Dismantling Method Per Dryer Ass’y

PANEL FRONT ASS’Y / PLATE TOP ASS’Y ...................................................................................................................65

CABINET FRONT ASS’Y ..................................................................................................................................................66

FRAME UPPER / SEPARATION OF LAMP,PCB MAIN CONNECTOR..........................................................................67

PCB MAIN / DUCT OUTLET ASS’Y .................................................................................................................................68

SUPPORT DRUM FRONT ASS’Y / DRUM ASS’Y / PIPE EXHAUST.............................................................................69

COVER BACK / SUPPORT DRUM REAR ASS’Y............................................................................................................70

MOTOR CONNECTOR .....................................................................................................................................................71

TERMINAL BLOCK............................................................................................................................................................72

MOTOR ASS’Y ..................................................................................................................................................................73

HEATER ASS’Y / LAMP ASS’Y ........................................................................................................................................75

FILTER DUST ASS’Y / HUMIDTY SENSOR....................................................................................................................76

DOOR ASS’Y.....................................................................................................................................................................77

GAS BURNER ASS’Y........................................................................................................................................................79