5

A

As

sl

la

an

n

M

Ma

ac

ch

hi

in

ne

e,

,

I

In

nc

c.

.i

in

nf

fo

o@

@a

as

sl

la

an

nm

ma

ac

ch

hi

in

ne

e.

.c

co

om

m,

,

T

Te

el

l:

:

+

+1

1

3

30

01

1

5

52

28

8

1

16

69

96

6

2. MACHINE’S DESCRIPTION AND PURPOSE OF USE

2.1. MACHINE’S DESCRIPTION

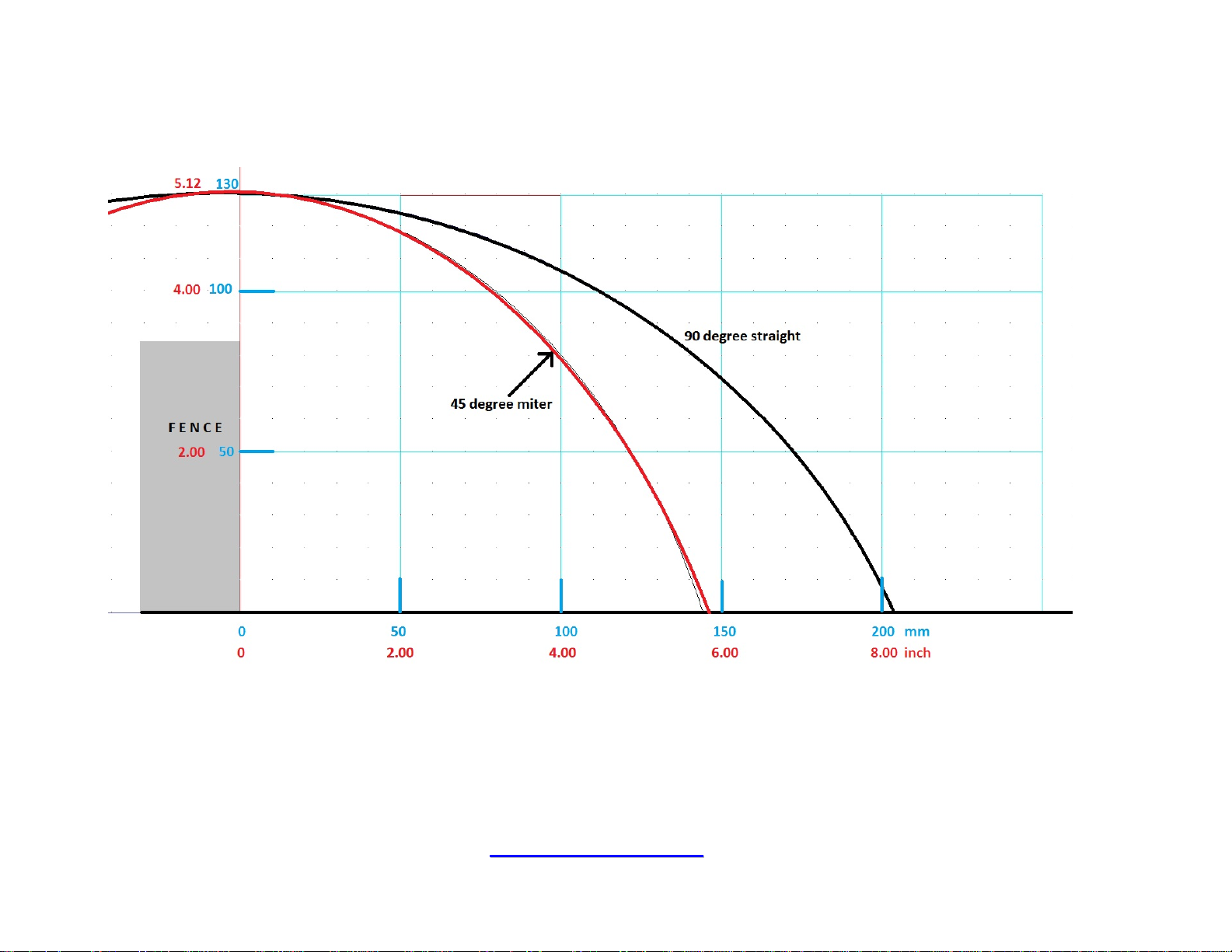

This is an automatic up-cut saw with a circular saw blade for cutting PVC, aluminum and

wood profiles at straight and miter angles. The operator can adjust the cutting speed of

the saw blade via a knob on the air piston for the material type and the size.

The features of this machine:

Cutting at fixed angles such as 150, 22.50, 300, 450, 900, and at intermediate angles by

setting arm.This machine has been designed according to CE Safety Directives.

The movable back fence enables straight and miter cut for wide materials.

The cutting speed can be adjusted manually for each material type.

If the top safety cover and/or the front door is opened during a cutting operation, the

power to the saw blade motor is interrupted for safety.

After the cutting is finished, the saw blade moves down automatically.

Please include the following information in all your correspondences.

*Machine’s model

*Machine’s serial number

*Voltage and frequency

*Name of dealer where machine was purchased

*Date of purchase

*Description of the machine fault

*Average daily operation period