OM00020 Rev 2, FP00091, FP00101 Operation Manual Page 2of 15

Contents

System Information ......................................................................................................................................3

Safety ............................................................................................................................................................3

General Operation ........................................................................................................................................4

Environmental...........................................................................................................................................4

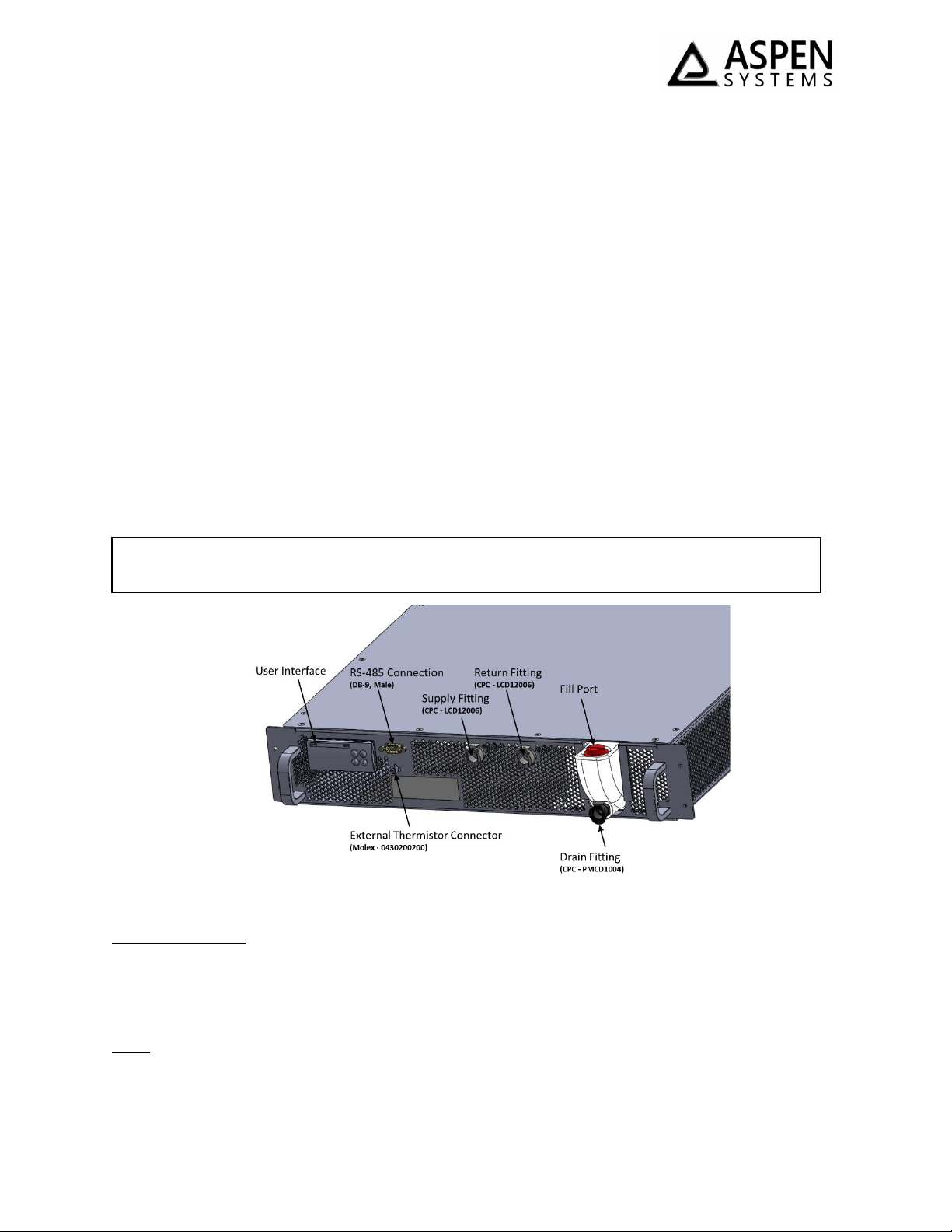

Coolant Interface ......................................................................................................................................4

Coolant Connections.............................................................................................................................4

Filling.....................................................................................................................................................4

Draining.................................................................................................................................................5

Airflow...................................................................................................................................................5

Other Considerations............................................................................................................................5

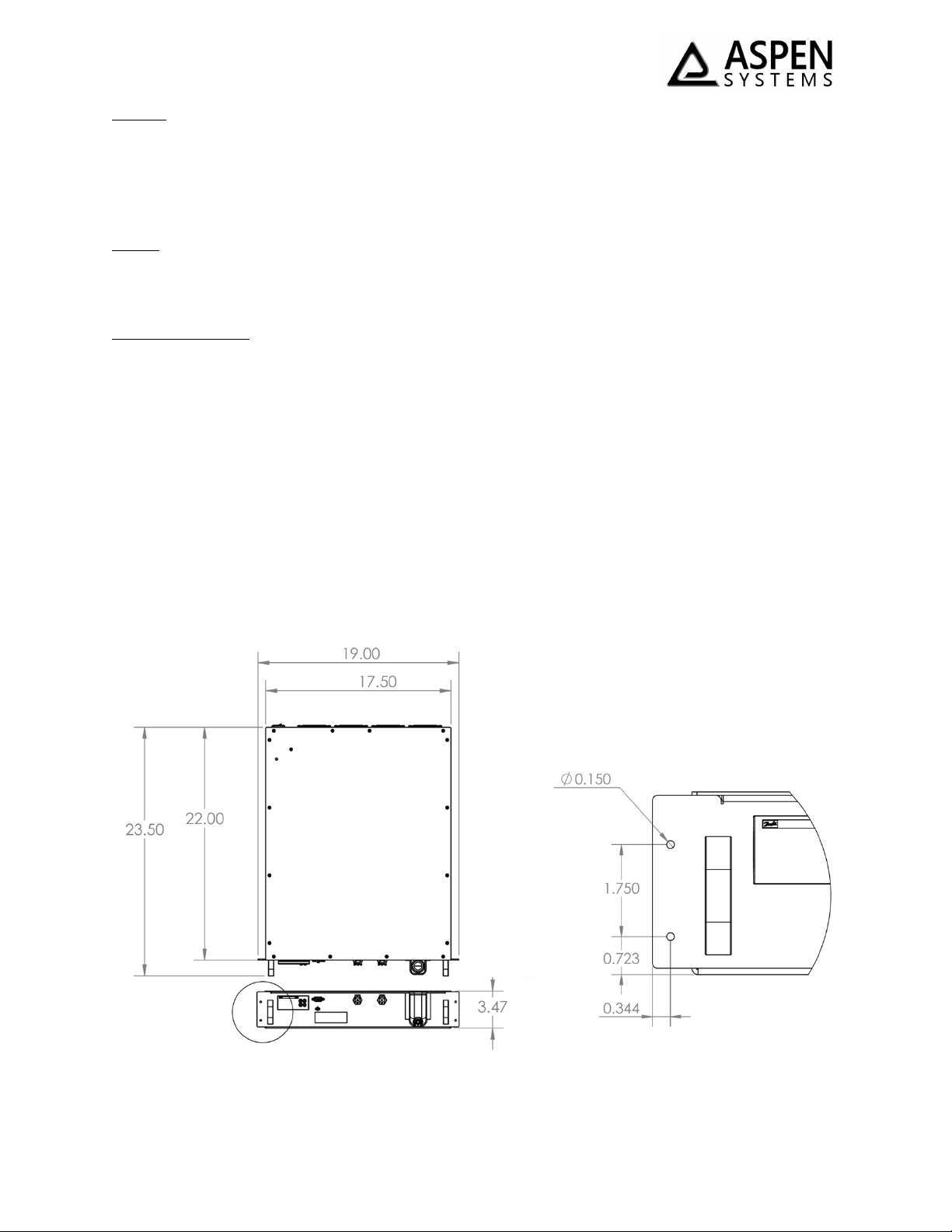

Mounting...................................................................................................................................................5

Electrical Interface ....................................................................................................................................6

External Thermistor ..................................................................................................................................6

Performance .................................................................................................................................................6

Cooling Capacity........................................................................................................................................6

Performance Curves..................................................................................................................................6

Coolant Flow Rate.....................................................................................................................................7

Controller Interface.......................................................................................................................................8

Primary Functionality................................................................................................................................8

Changing the Setpoint ..........................................................................................................................8

Starting the RMC...................................................................................................................................9

Turning off the RMC..............................................................................................................................9

Operating Modes..................................................................................................................................9

Parameter Tree .......................................................................................................................................10

Controller Login.......................................................................................................................................11

System Errors..........................................................................................................................................11

Faults...................................................................................................................................................11

Clearing Faults.....................................................................................................................................11

Warnings.............................................................................................................................................11

Communication...........................................................................................................................................11

Maintenance...............................................................................................................................................14

Customer Service ........................................................................................................................................14

Commercial Product Warranty ...............................................................................................................14

Warranty Repairs ....................................................................................................................................15

Technical Support ...................................................................................................................................15

Aspen Contact Information.....................................................................................................................15