Aspero IMPOS 4012 User manual

1

MANUAL

www.dejedamachine.com

SICHERHEITSZEICHEN

BEDEUTUNG

DER

SYMBOLE

SAFETY

SIGNS

DEFINITION

OF

SYMBOLS

@

(

DE

)

WARlNUNG

!

Beachten

Sie

die

Sicherheitssymbole

!

Die

Nichtbeachtung

der

Vorschriften

und

Hinweise

zum

Einsatz

des

Erdbohrers

kann

zu

schweren

Personenschaden

und

todfiche

Gefahren

mit

sich

bringen

.

(

EIN

)

ATTENTION

*

Ignoring

the

safety

signs

and

warnings

applied

on

the

ma

-

chine

as

well

as

ignoring

the

security

and

operating

instructions

can

cause

serious

injuries

and

even

lead

to

death

.

©

©

^

Dlj

)

ANLEITUNG

LESEN

*

Lesen

Sie

die

Betriebs

-

und

Wartungsan

/

eitung

Ihrer

Maschine

aufmerksam

durch

und

machen

Sie

sich

mit

den

Bedienelementen

der

Maschine

gut

vertraut

urn

die

Maschine

ordnungsgemaB

zu

bedienen

und

so

Schaden

an

Mensch

und

Maschine

vorzubeugen

.

READ

THE

MANUAL

*

Read

the

user

and

maintenance

manual

carefully

and

get

familiar

with

the

controls

n

order

to

use

the

machine

correctly

and

to

avoid

injuries

and

machine

defects

.

©

©

(

DE

)

SCHUTZAUSRUSTUNG

!

Das

Tragen

sowie

Sicherheitsschuhen

ist

Pflicht

.

CEN

^

PROTECTIVE

CLOTHING

*

The

operator

is

obligated

to

wear

proper

ear

protection

,

safety

goggles

and

safety

shoes

0

von

Gehorschutz

,

Schutzbrille

©

©

m

2

www.dejedamachine.com

CpEp

VERBRENNUNGSGEFAHR

!

-

HeiBe

Abgase

.

Motorabdeckung

sowie

Vergaser

werden

wahrend

dem

Betrieb

he

/

B

.

BURN

HAZARD

!

-

Hot

exhaust

fumes

.

Engine

parts

and

muffler

become

hot

during

operation

.

(

pi

)

LEICHT

ENTFLAMMBAR

!

-

Offenes

Feuer

,

Rauchen

und

offenes

Licht

sind

strengstens

verboten

!

QENQ

HIGHLY

FLAMMABLE

!

-

Smoking

,

fire

and

open

light

are

forbidden

!

ES

FR

CE

-

KONFORM

?

-

Dieses

Produkt

entspricht

den

EG

-

Richtlinien

.

CE

-

Conformal

!

-

This

product

complies

with

the

EC

-

directives

.

<

ES

)

©

3

%

www.dejedamachine.com

4

www.dejedamachine.com

5

www.dejedamachine.com

6

www.dejedamachine.com

7

www.dejedamachine.com

8

www.dejedamachine.com

9

www.dejedamachine.com

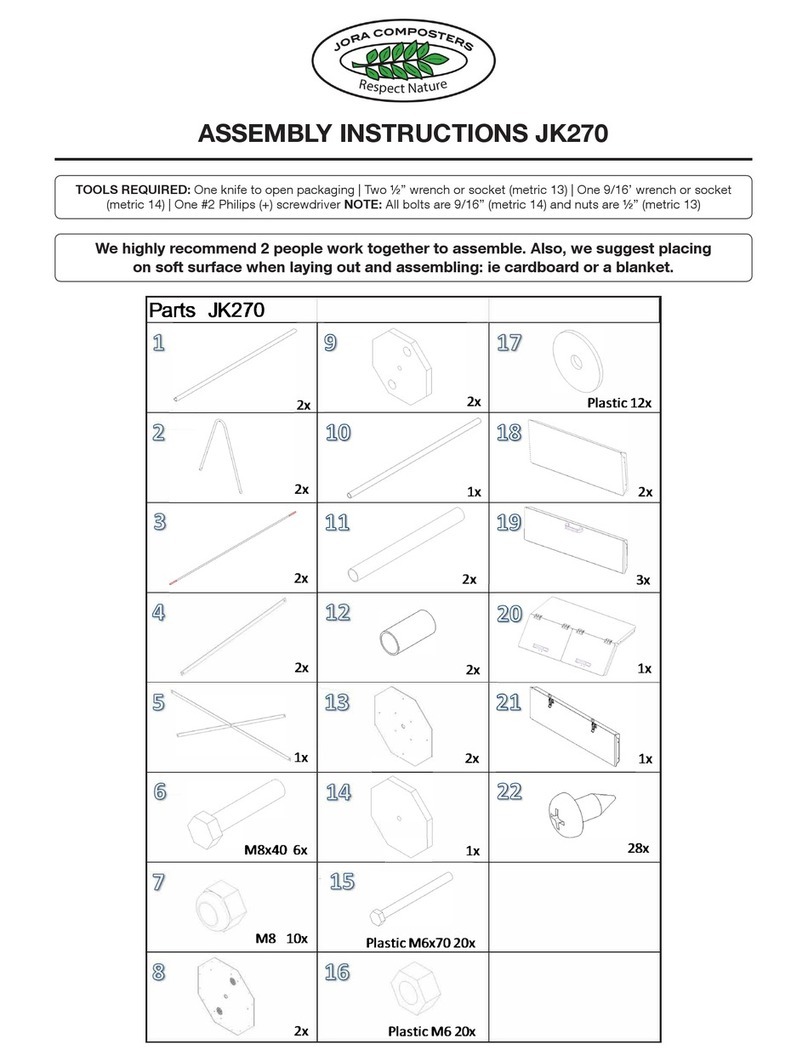

-

2.1

Components

(

Fig

.

A

)

1

Engine

USER

MANUAL

2

Extension

pole

3

Hedge

trimmer

Dear

Customer

!

This

manual

contains

important

information

and

advice

for

the

correct

and

safe

use

and

maintenance

of

the

IMPOS

garden

maintenance

set

4012

.

The

manual

is

part

of

the

machine

and

.

may

not

be

stored

separately

.

Read

it

profoundly

before

first

use

of

the

machine

and

keep

it

for

later

reference

.

When

the

machine

is

handed

to

other

persons

always

put

the

manual

to

the

ma

-

chine

.

4

Twig

saw

5

Brush

cutter

6

Trimmer

7

Scythe

blade

i

8

Safety

cover

9

Angle

adjustment

hedge

trimmer

10

Belt

11

Pole

with

control

panel

Please

follow

the

security

instructions

!

Due

to

continuous

development

of

our

products

illustrations

,

pictures

might

differ

slightly

.

2.2

Technical

Details

Engine

type

2

-

stroke

engine

Displacement

25

,

4

cm

3

Attention

!

Technical

changes

reserved

!

0

,

7

kW

Engine

power

10300

rpm

Maximum

engine

speed

i

Copyright

©

2010

This

manual

is

protected

by

copyright

law

-

all

rights

reserved

.

Especially

the

reprinting

as

well

as

the

translation

and

depiction

of

pictures

will

be

prosecuted

by

law

.

Court

of

jurisdiction

is

WELS

,

Austria

.

2800

rpm

Idle

speed

Starter

Reverse

starter

CDI

Ignition

Fuel

capacity

0

,

7

Litres

25

:

1

Ratio

fuel

:

oil

5

/

7

kg

Weight

Trimmer

:

2

-

thread

head

Customer

Support

:

Maximum

cutting

width

455

mm

Thread

length

2

,

5

m

Thread

thickness

02

,

4

mm

T

:

Leaf

scythe

:

3

-

tooth

blade

0255

x

025

,

4

x

1

,

5

Blade

dimensions

Twig

saw

:

Carlton

sword

10

www.dejedamachine.com

Lagos, Nigeria

Ojo Alaba, Ojo

G76 Alaba International Market,

Tel: +234 803 577 9094

DE JEDA MACHINE AND TOOLS LIMITED

www.dejedamachine.com

1500

mm

Length

fern

25

,

4

cm

Hedge

trimmer

:

180

°

adjustable

Maximum

cutting

length

400

mm

SworcJ

length

Do

not

wear

loose

clothing

,

long

hair

openly

or

loose

jewellery

like

necklaces

etc

.

when

operating

the

machine

They

might

be

catched

by

rotating

parts

and

cause

serious

injuries

.

Technical

changes

reserved

.

2.3

Included

in

delivery

Unpack

the

IMPOS

garden

maintenance

set

4012

and

check

the

machine

for

any

transport

damage

and

for

completeness

of

delivery

.

|

Burning

Hazard

!

During

working

hot

i

?

i

exhaust

gases

escape

and

some

parts

like

the

engine

are

getting

very

hot

.

2.4

SAFETY

INSTRUCTIONS

The

IMPOS

garden

maintenance

set

4012

shall

only

be

used

for

mowing

and

trimming

grass

at

moderate

and

non

-

siippery

terrain

and

for

cutting

twigs

and

hedges

.

-

j

Always

be

focused

when

working

,

take

{

care

to

maintain

a

safe

posture

at

every

i

time

.

Do

not

use

the

machine

on

a

slope

!

steeper

than

20

°

.

Do

not

work

on

slippery

ground

.

The

operation

of

the

machine

on

icy

or

snowy

ground

is

forbidden

!

Slipping

/

stumbling

/

falling

down

are

a

frequent

cause

of

severe

injuries

.

:

:

Using

saw

blades

for

the

machine

is

for

-

bidden

!

ZIPPER

MASCHINEN

cannot

be

held

responsible

for

any

injuries

or

damages

if

there

was

per

-

formed

manipulation

or

adjustments

to

the

ma

-

chine

.

J

Use

proper

safety

clothing

and

devites

SjjjjjBk

when

operating

the

machine

(

safety

gloves

,

safety

goggles

,

ear

protectors

,

safety

shoes

.

..

)

!

Do

not

operate

the

machine

at

insuffi

-

cient

lighting

conditions

.

Do

not

operate

the

machine

when

you

are

tired

,

when

your

concentration

is

impaired

,

and

/

or

under

the

influence

of

drugs

,

medication

or

alcohol

.

The

machine

may

only

be

operated

outdoors

.

If

there

are

some

components

still

hot

,

the

machine

won

'

t

be

allowed

to

be

stored

.

The

machine

shall

be

used

only

by

trained

persons

.

Non

authorized

persons

,

especially

children

,

shall

be

kept

away

from

the

work

area

.

i

11

Do

not

change

the

mowing

attachment

.

W

A

R

N

I

N

G

www.dejedamachine.com

2.4

.

1

Remaining

risks

•

Danger

by

sound

:

Working

without

ear

protectors

can

damage

the

hearing

.

•

Danger

by

the

working

area

:

Take

care

of

stones

and

other

things

that

can

fly

around

and

of

failing

down

twigs

.

•

Danger

for

the

hands

(

fingers

)

:

Never

touch

the

mowing

attachment

,

the

hedge

trimmer

or

the

twig

saw

during

the

operation

.

After

operation

the

machine

has

to

get

cold

.

Otherwise

,

there

'

s

a

high

burning

hazard

!

During

refuelling

open

light

,

fire

or

smoking

is

forbidden

.

Don

'

t

refuel

when

the

engine

'

s

running

or

some

components

are

still

hot

.

Only

refuel

outdoors

or

in

good

ventilated

rooms

.

Always

wipe

off

spilt

fuel

immediately

.

Fuel

is

flammable

very

easily

!

doesn

'

t

start

you

'

ll

have

to

push

the

but

-

ton

some

times

more

.

•

When

the

engine

'

s

running

,

you

have

to

turn

the

choker

17

off

again

(

Fig

.

I

)

.

2.6

.

2

Warm

starting

•

Turn

on

the

ignition

16

(

Fig

.

H

)

.

•

Let

the

choker

17

turned

off

(

Fig

.

F

)

.

•

Do

the

next

steps

like

cold

starting

.

2.63

Stopping

•

Turn

the

ignition

16

to

the

position

0

(

Fig

.

:

J

2.5

Assembly

•

Mount

the

pole

with

the

control

panel

11

on

the

engine

(

Fig

.

B

)

.

•

Then

you

have

to

fit

the

handle

28

on

the

extension

pole

2

(

Fig

.

C

)

.

•

Now

fix

the

safety

cover

8

on

the

brush

cut

-

ter

like

shown

in

Fig

.

D

.

•

Then

the

slot

for

the

attachments

29

has

to

be

fitted

on

the

pole

(

Fig

.

D

)

.

•

Then

mount

the

twig

saw

4

like

shown

in

Fig

E

.

on

the

related

pole

.

•

Then

you

have

to

fit

the

belt

10

into

the

re

-

lated

hole

(

Fig

.

A

)

.

H

)

•

Wait

till

the

engine

stands

still

and

all

components

are

cold

again

.

2.6

.

4

Regulating

the

engine

speed

•

For

this

you

have

to

use

the

throttle

handle

shown

in

Fig

.

L

.

•

At

first

you

have

to

push

the

lock

handle

18

.

2.6

Operation

Instructions

Now

the

throttle

handle

19

can

be

pushed

.

IMPORTANT

2.7

Operation

Do

not

operate

the

engine

at

i

maximum

speed

right

from

the

start

.

The

engine

itself

reaches

its

maximum

capacity

after

the

first

10

hours

of

operation

.

Non

-

compliance

j

with

this

instruction

reduces

your

I

engine

lifespan

substantially

.

2.6

.

1

Cold

starting

•

Turn

the

ignition

16

to

the

position

I

(

Fig

.

For

operation

all

safety

devices

and

the

belt

must

be

used

!

2.7

.

1

Mounting

the

operation

attachments

For

this

work

the

engine

has

to

stand

still

!

Loosen

the

hand

screw

12

.

Then

push

the

safety

cover

13

to

the

outside

.

Push

the

handle

being

under

the

safety

cover

and

remove

the

pole

with

the

engine

.

Put

the

new

pole

with

the

attachment

into

the

hole

.

Push

the

handle

again

and

take

care

that

the

hook

at

the

inside

of

the

pole

fits

into

the

hole

.

H

)

.

•

Turn

the

choker

17

into

the

position

like

shown

in

Fig

.

3

.

•

Now

push

the

button

28

3

to

5

times

(

Fig

.

K

)

.

•

Pul

!

at

the

cable

control

20

powerfully

to

start

the

engine

(

Fig

.

M

)

.

When

the

engine

12

www.dejedamachine.com

•

Push

the

cover

13

to

the

pole

and

fasten

the

hand

screw

12

again

.

2.7

.

2

Operation

brush

cutter

•

Changing

the

mowing

attachment

For

the

blade

you

have

to

use

the

nut

.

The

trimmer

is

fitted

by

the

threaded

hole

.

•

Operation

with

the

blade

(

Fig

.

U

)

Start

the

machine

.

Now

hang

the

belt

round

your

neck

.

Operate

the

throttle

handle

and

start

mowing

like

shown

on

the

picture

.

•

Operation

with

the

trimmer

Do

that

like

mowing

with

the

blade

.

2.7

.

3

Operation

twig

saw

(

Fig

.

V

)

•

Take

care

that

you

aren

'

t

standing

under

the

twig

you

want

to

cut

.

•

Remove

the

safety

cover

.

•

Start

the

engine

.

•

Hang

the

belt

around

your

neck

.

«

Position

the

saw

where

you

want

to

cut

.

•

Operate

the

throttle

handle

and

cut

the

twig

carefully

from

the

upper

to

the

lower

side

.

No

cleaning

,

upkeep

,

checks

or

maintenance

when

machine

is

run

-

ning

Be

safe

:

Shut

off

the

machine

,

let

it

cool

down

,

disconnect

spark

plug

cap

from

spark

plug

.

The

machine

does

not

require

intense

mainten

-

ance

.

However

,

to

ensure

a

long

lifespan

,

we

strongly

recommend

following

the

upkeep

and

maintenance

plan

.

Repairs

must

be

carried

out

by

specialists

!

Use

original

ZIPPER

parts

only

!

2.8

.

1

Maintenance

plan

Controls

for

the

maintenance

of

the

machine

Regularly

prior

to

each

operation

Loose

or

lost

screws

,

nuts

,

bolts

Regularly

prior

to

each

operation

Damage

of

any

part

of

the

machine

Machine

cleaning

Regularly

after

operation

Every

25

working

hours

Cleaning

spark

plug

Cleaning

air

filter

Every

20

-

30

working

hours

2.7

.

4

Operation

hedge

trimmer

•

Adjustment

of

the

cutting

angle

(

Fig

.

G

)

Push

the

lock

handle

14

.

Then

operate

the

handle

15

.

Now

turn

the

hedge

trimmer

to

the

required

position

.

Stop

pushing

the

handles

.

Take

care

that

both

latch

into

position

.

•

Horizontal

cuts

(

Fig

.

W

)

Adjust

the

required

cutting

angle

.

Remove

the

safety

covers

.

Start

the

machine

and

hang

the

belt

round

your

neck

.

Now

cut

the

hedge

like

shown

on

the

picture

.

•

Vertical

cuts

(

Fig

.

X

)

Do

this

like

cutting

horizontal

cuts

.

Cut

the

hedge

like

shown

on

the

picture

.

2.8

.

2

Cleaning

Clean

'

the

machine

and

the

working

attachment

from

soil

,

dust

,

grass

,

chips

,

and

small

twigs

,

etc

.

Clean

the

machine

housing

with

a

wet

cloth

and

a

mild

cleaning

solution

.

Put

on

all

coatless

flats

a

thin

coat

of

oil

.

IMPORTANT

The

usage

of

solvents

,

aggressive

chemicals

or

scouring

agents

damages

the

machine

housing

.

2.8

.

3

Refuelling

The

machine

is

run

by

a

gasoline

-

oii

mixture

.

You

need

for

the

2

-

Stroke

engine

a

fuel

mixture

of

25

:

1

(

gasoline

:

oil

)

.

Ensure

yourself

that

no

particles

get

into

the

fuel

tank

21

when

refuelling

(

Fig

.

M

)

.

Use

a

filter

.

2.8

13

I

*

WARNING

Maintenance

www.dejedamachine.com

ZIPPER

MASCHINEN

strongly

recommends

the

usage

of

HQ

premixed

fuels

especially

recommended

for

2

-

stroke

motors

.

Many

of

them

keep

their

consistency

even

after

long

periods

of

storage

.

If

you

prefer

to

mix

your

own

fuel

please

use

HQ

Synthetic

Oil

for

2

-

stroke

engines

.

Synthetic

oil

reduces

accumulation

of

soot

on

the

spark

plug

,

cylinder

,

engine

cock

and

exhaust

pipe

.

This

increases

the

degree

of

lubrication

and

prolongs

the

engines

lifespan

.

Use

self

-

mixed

fuel

up

within

4

weeks

.

2.8

.

7

Changing

the

chain

•

Loosen

the

nut

32

and

remove

the

cover

33

(

Fig

.

V

)

.

a

Loosen

the

chain

.

©

Remove

the

chain

,

*

At

fitting

the

new

chain

you

have

to

take

care

that

all

the

guides

slide

in

the

grooves

34

(

Fig

.

Z

)

.

2.8

.

8

Changing

the

shears

©

At

first

you

have

to

loosen

the

nuts

35

and

36

(

Fig

.

a

)

.

Mow

remove

the

nuts

37

(

Fig

.

b

)

.

Then

dismantle

the

guiding

bar

38

(

Fig

.

IMPORTANT

Shake

fuel

tank

prior

to

every

;

usage

!

During

storage

oil

descents

slowly

in

the

fuel

tank

.

If

you

start

the

engine

under

this

j

condition

,

it

has

barely

any

j

lubrication

which

would

lead

to

I

severe

engine

damage

,

J

2.8

.

4

Cleaning

the

air

filter

A

clogged

air

filter

reduces

the

engines

power

output

drastically

and

causes

engine

disfunction

.

Furthermore

it

reduces

the

engines

lifespan

!

Loosen

the

nut

22

and

remove

the

cover

of

the

air

filter

23

(

Fig

.

0

)

.

Take

out

the

air

filter

(

Fig

.

P

)

and

clean

the

air

filter

(

Fig

.

Q

)

with

water

.

Wring

it

out

strongly

.

Let

it

dry

.

Drip

some

drops

of

oil

onto

the

filter

.

Mount

the

filter

back

and

fix

the

cover

again

.

2.8

.

5

Cleaning

the

spark

plug

Take

off

the

spark

plug

cap

26

(

Fig

.

S

)

.

Loosen

and

remove

the

spark

plug

27

(

Fig

.

T

)

carefully

.

Clean

it

with

a

small

brush

from

soot

debris

.

The

contact

distance

shall

account

approx

.

0

,

5

mm

or

~

credit

card

thickness

.

c

)

.

Mow

loosen

and

remove

the

screws

39

(

Fig

.

d

)

.

Loosen

the

socket

screws

40

and

remove

the

cap

41

(

Fig

.

e

)

.

Then

you

have

to

disassemble

the

gasket

42

and

the

safety

cover

43

(

Fig

,

f

)

.

Now

lift

the

connecting

rod

44

out

of

the

cam

gear

.

Take

care

that

you

do

not

lose

the

spacer

45

(

Fig

.

g

)

.

Now

you

can

change

the

shears

(

Fig

.

h

)

.

For

fitting

the

new

shears

you

have

to

do

these

steps

backwards

.

2.8

.

9

Lubrication

After

cleaning

you

have

to

lubricate

all

the

moving

parts

.

Spray

the

chain

with

a

chain

spray

.

Every

15

working

hours

you

must

squeeze

some

grease

into

the

grease

nipples

of

the

twig

saw

31

(

Fig

.

E

)

and

of

the

hedge

trimmer

32

(

Fig

.

G

)

.

2.8

.

10

Storage

2.8

.

6

Tensioning

the

chain

(

Fig

.

R

)

Adjust

the

chain

tension

that

it

isn

'

t

able

to

spring

out

of

the

guides

and

that

it

doesn

'

t

sit

too

fast

.

Turn

the

adjusting

screw

25

clockwise

to

tension

the

chain

and

anti

-

clockwise

to

loosen

When

the

machine

is

stored

longer

than

30

days

:

*

Drain

the

fuel

out

of

the

fuel

tank

.

•

Take

off

the

spark

plug

and

pour

some

drops

of

oil

into

the

cylinder

.

Turn

the

engine

some

times

using

the

cable

control

so

the

oil

in

the

cylinder

gets

evenly

it

.

14

www.dejedamachine.com

distributed

.

Clean

the

spark

plug

and

fit

it

again

.

*

Cover

the

machine

and

store

it

at

a

dry

and

clean

place

.

2.8

.

11

Controlling

the

oil

level

Before

using

the

twig

saw

you

have

to

control

the

oil

level

of

the

oil

tank

30

for

the

twig

saw

(

Fig

.

E

)

.

Refill

it

when

there

'

s

too

less

oil

in

it

.

2.8

.

12

Disposal

Do

not

dispose

your

IMPOS

4012

in

the

residual

waste

!

Contact

your

local

authorities

for

information

about

best

available

disposal

possibilities

in

your

area

.

Drain

fuel

from

the

fuel

tank

completely

before

disposing

the

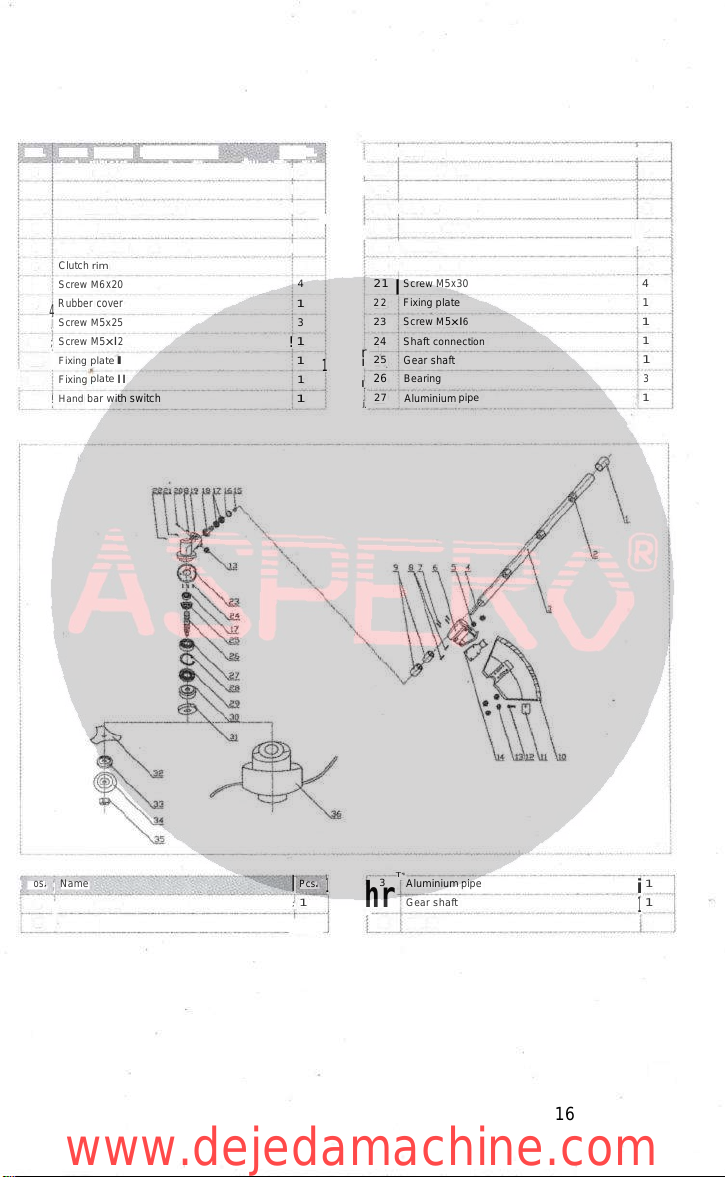

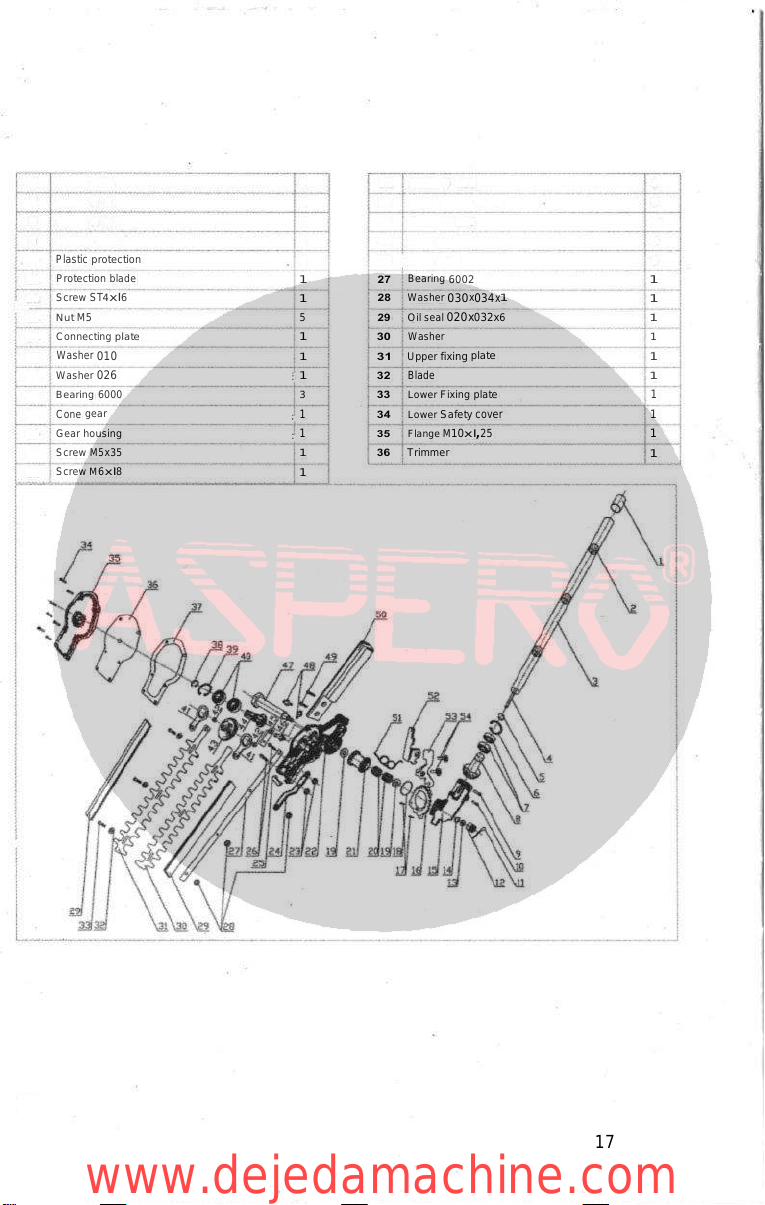

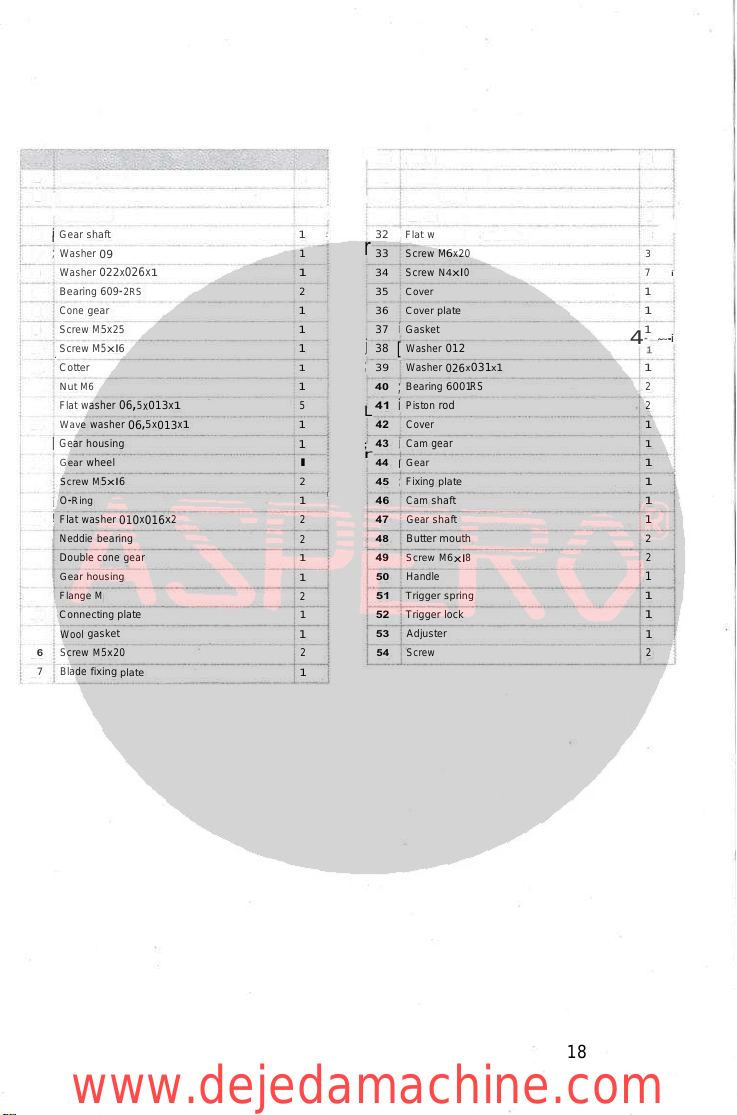

2.10

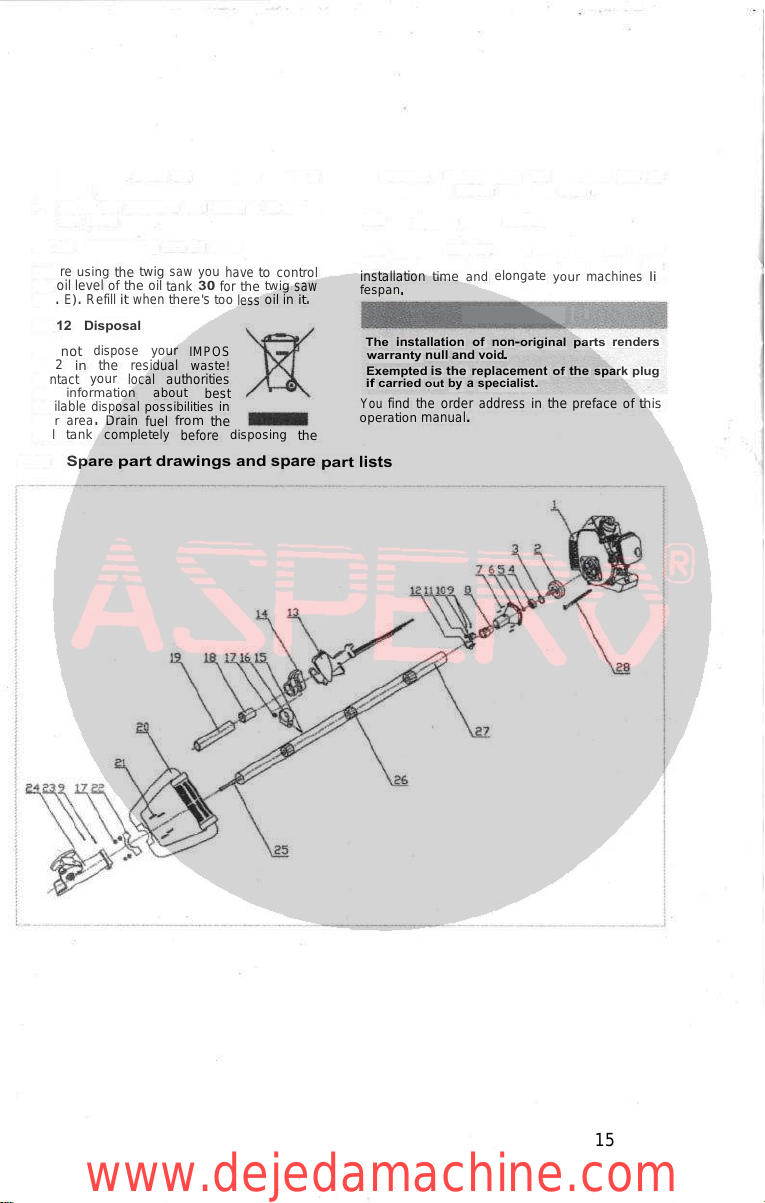

Spare

part

drawings

and

spare

part

lists

machine

.

Disaggregate

the

machine

into

its

components

before

disposing

them

.

2.9

Spare

part

order

With

original

ZIPPER

spare

parts

you

use

parts

that

are

attuned

to

each

other

and

shorten

the

installation

time

and

elongate

your

machines

li

-

fespan

.

The

installation

of

non

-

original

parts

renders

warranty

null

and

void

.

Exempted

is

the

replacement

of

the

spark

plug

if

carried

out

by

a

specialist

.

You

find

the

order

address

in

the

preface

of

this

operation

manual

.

15

WARNING

www.dejedamachine.com

•

»

Pos

.

Name

NMRM

(

WttMlMHHi

HPI

.

»

.

v

i

w

.

-

.

-

v

,

n

.

-

v

-

_

-

2

,

-

,

.

.

-

i

ip

<

:

-

—

-

.

i

Pcs

.

i

1

14

!

Belt

ring

r

is

!

16

17

i

Nut

M

5

Screw

M

5

x

25

1

1

Engine

34

F

2

Clutch

3

Flat

washer

032

x

038

x

1

,

5

4

Bearing

6202

Spring

washer

013

x

017

x

1

Clutch

rim

Screw

M

6

x

20

!

1

1

i

1

i

1

5

H

!

:

1

!

18

Rubber

cover

!

1

T

:

i

19

|

Handle

pole

20

i

Handle

bar

1

5

1

1

6

7

21

|

Screw

M

5

x

30

4

4

Fixing

plate

1

Rubber

cover

1

22

8

4

23

9

j

Screw

M

5

x

25

3

Screw

M

5

xl

6

1

!

1

Shaft

connection

1

10

;

Screw

M

5

xl

2

11

|

Fixing

plate

I

Fixing

plate

II

13

!

Hand

bar

with

switch

24

r

i

25

Gear

shaft

1

1

1

1

12

1

3

26

Bearing

I

.

27

Aluminium

pipe

1

1

j

.

T

*

*

..

i

I

Pcs

-

1

i

Pos

,

;

Name

1

[

Safety

2

|

Bearing

3

Aluminium

pipe

i

1

hr

Gear

shaft

1

1

;

1

cover

I

-

5

Nut

M

5

2

±

L

,

„

16

I

i

t

i

www.dejedamachine.com

Fixing

plate

Screw

M

5

x

20

6

22

Screw

M

6

xl

2

1

1

7

23

4

Upper

safety

cover

1

8

Screw

M

5

x

25

3

24

Screw

M

5

xl

0

3

9

Rubber

cover

2

25

Cone

gear

1

26

|

Cone

gear

Plastic

protection

10

1

1

Protection

blade

11

27

Bearing

6002

1

1

12

Screw

ST

4

xl

6

28

Washer

030

x

034

x

1

1

1

I

—

13

Nut

M

5

Oil

seal

020

x

032

x

6

5

29

1

14

Connecting

plate

1

Washer

30

1

Washer

010

15

1

31

Upper

fixing

plate

1

.

Washer

026

16

32

Blade

:

1

1

17

Bearing

6000

3

33

Lower

Fixing

plate

1

Cone

gear

18

34

;

1

Lower

Safety

cover

Flange

M

10

xl

,

25

1

19

Gear

housing

:

1

35

1

20

Screw

M

5

x

35

1

36

Trimmer

1

21

Screw

M

6

xl

8

1

!

17

r

i

r

r

www.dejedamachine.com

r

Pos

.

Name

Pcs

.

28

Nut

M

6

:

3

2

1

Rubber

cover

1

29

Blade

protection

2

j

Bearing

3

;

30

Upper

blade

31

Lower

blade

1

I

'

'

!

3

Aluminium

pipe

4

i

Gear

shaft

1

1

:

H

32

I

Flat

washer

06

,

5

x

018

x

2

33

Screw

M

6

x

20

34

Screw

N

4

xl

0

3

1

:

I

r

5

;

Washer

09

6

Washer

022

x

026

x

1

7

Bearing

609

-

2

RS

8

Cone

gear

3

1

1

7

i

2

35

Cover

1

1

36

Cover

plate

37

i

Gasket

j

38

[

Washer

012

;

39

Washer

026

x

031

x

1

40

;

Bearing

6001

RS

41

i

Piston

rod

1

9

Screw

M

5

x

25

1 1

4

*

~

~

-

-

i

10

Screw

M

5

xl

6

1

.

11

Cotter

1

1

2

12

Nut

M

6

1

13

Flat

washer

06

,

5

x

013

x

1

14

Wave

washer

06

,

5

x

013

x

1

15

|

Gear

housing

16

Gear

wheel

5

2

L

1

42

Cover

1

;

43

j

Cam

gear

1

1

r

l

44

|

Gear

1

17

Screw

M

5

xl

6

2

45

;

Fixing

plate

46

Cam

shaft

1

{

18

j

O

-

Ring

19

!

Flat

washer

010

x

016

x

2

1

1

2

Gear

shaft

47

1

20

Neddie

bearing

2

48

Butter

mouth

2

21

Double

cone

gear

Gear

housing

49

Screw

M

6

xl

8

2

1

22

Handle

1

50

1

23

Flange

M

24

Connecting

plate

2

Trigger

spring

1

51

Trigger

lock

1

52

1

25

Wool

gasket

1

53

Adjuster

1

Screw

M

5

x

20

Blade

fixing

plate

2

Screw

2

26

54

27

1

18

www.dejedamachine.com

Pcs

.

Pos

.

Name

Rubber

cover

1

1

3

2

Bearing

3

Blade

fixing

plate

4

Aluminium

pipe

1

I

3

5

Chain

saw

assembly

1

:

6

|

Safety

cover

1

19

www.dejedamachine.com

Table of contents