8

ED5860 (B) Series

Installation Instructions

Exit Device

FM544 02/20

For installation assistance contact Corbin Russwin

1-800-543-3658 • techsupport.corbinrusswin@assaabloy.com

Copyright © 1998, 2020 ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole

or in part without the express written permission of ASSA ABLOY Access and Egress Hardware Group, Inc. is prohibited.

5 Pre-Installation (continued)

d Prepare Door, Frame and Sill

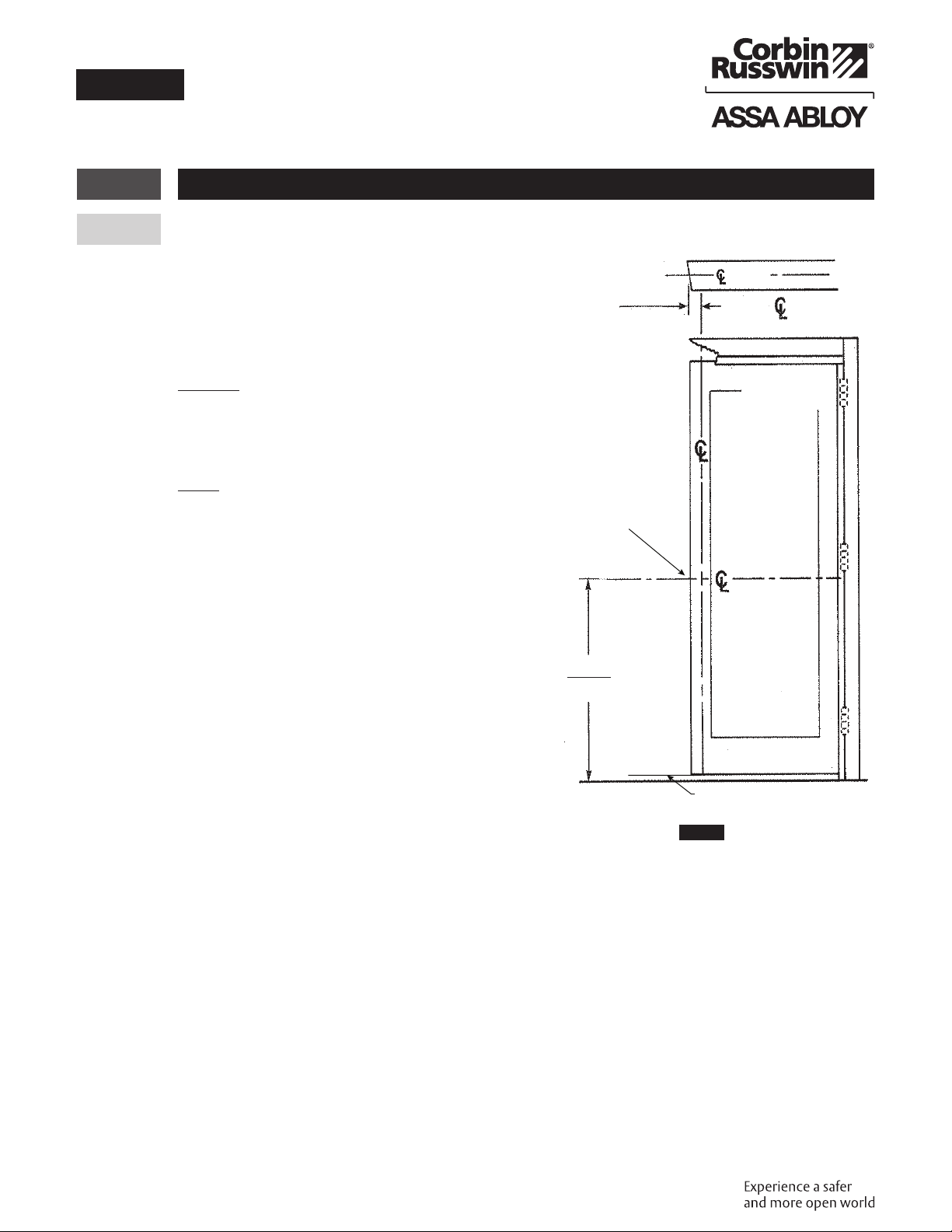

1. Locate device paper template aligning

VERTICAL REFERENCE and HORIZONTAL

REFERENCE lines on door and template. Tape

template to door face. (Figure 7)

2. Extend centerline of rod and strikes from

device paper template to door top and

bottom, on door face.

3. Locate top strike and bottom strike templates,

aligned on centerline of rods and strikes on

door.

4. Tape templates in place and mark holes.

(Figure7)

Note:

Auxiliary door marker is included to verify

correct door preparation. Reinforced doors

and frames, with factory made cutouts, are

recommended.

5. Locate and tape trim template to door.

(See instructions packed with trim)

6. Mark and prepare holes per installation

template.

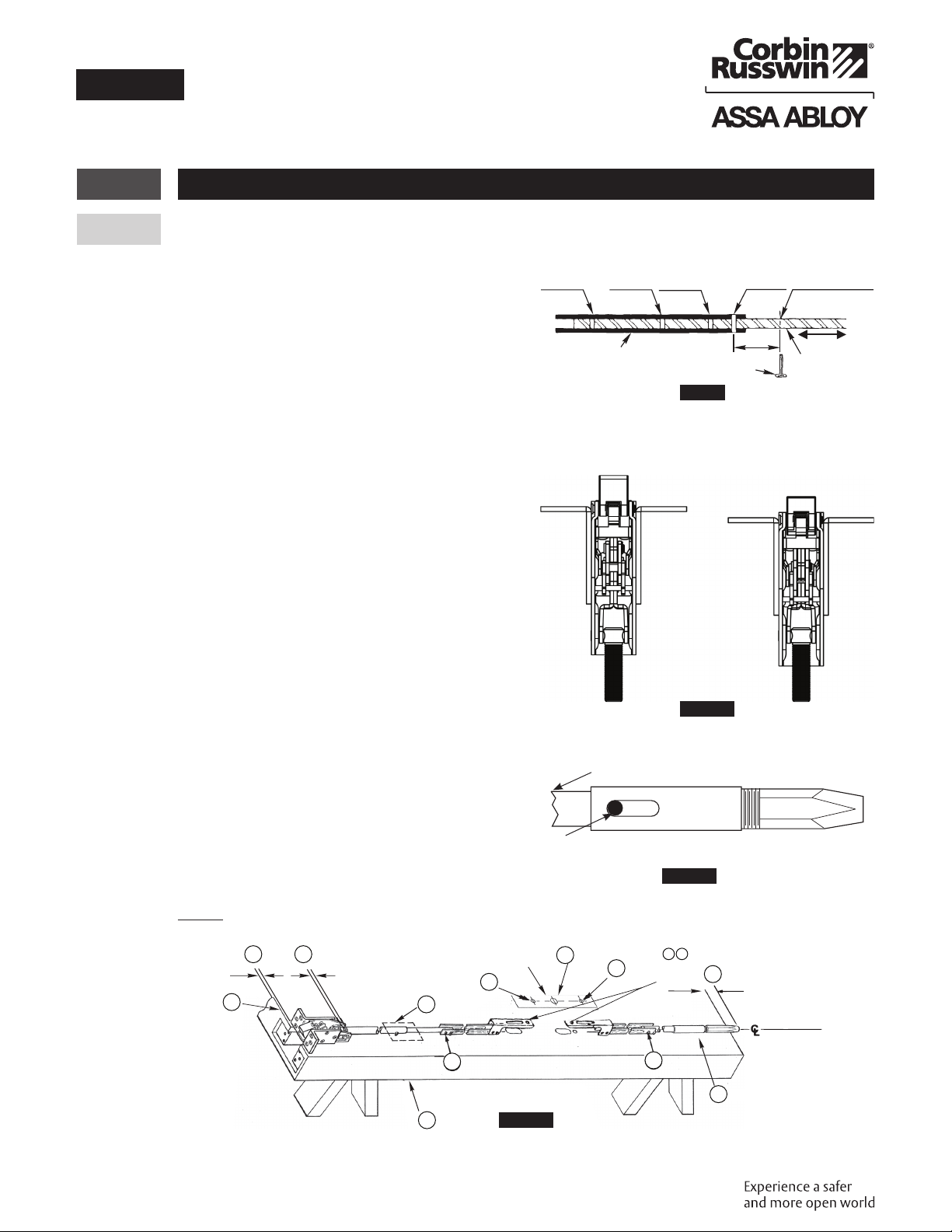

Device and Bolt Case Plates: Use two (2) 1/4-20

machine screws for metal reinforced doors OR

two (2) 3/8"(10) diameter sex nuts and bolts for each.

Top Strike: Use two (2) 10-24 machine screws.

Note:

Third screw MUST ONLY be used to lock strike in final position (See "Rod Assembly and Preliminary

Adjustment" Step 7).

Bottom Strike: 5/8"(16) diameter x 3/4"(19) deep hole.

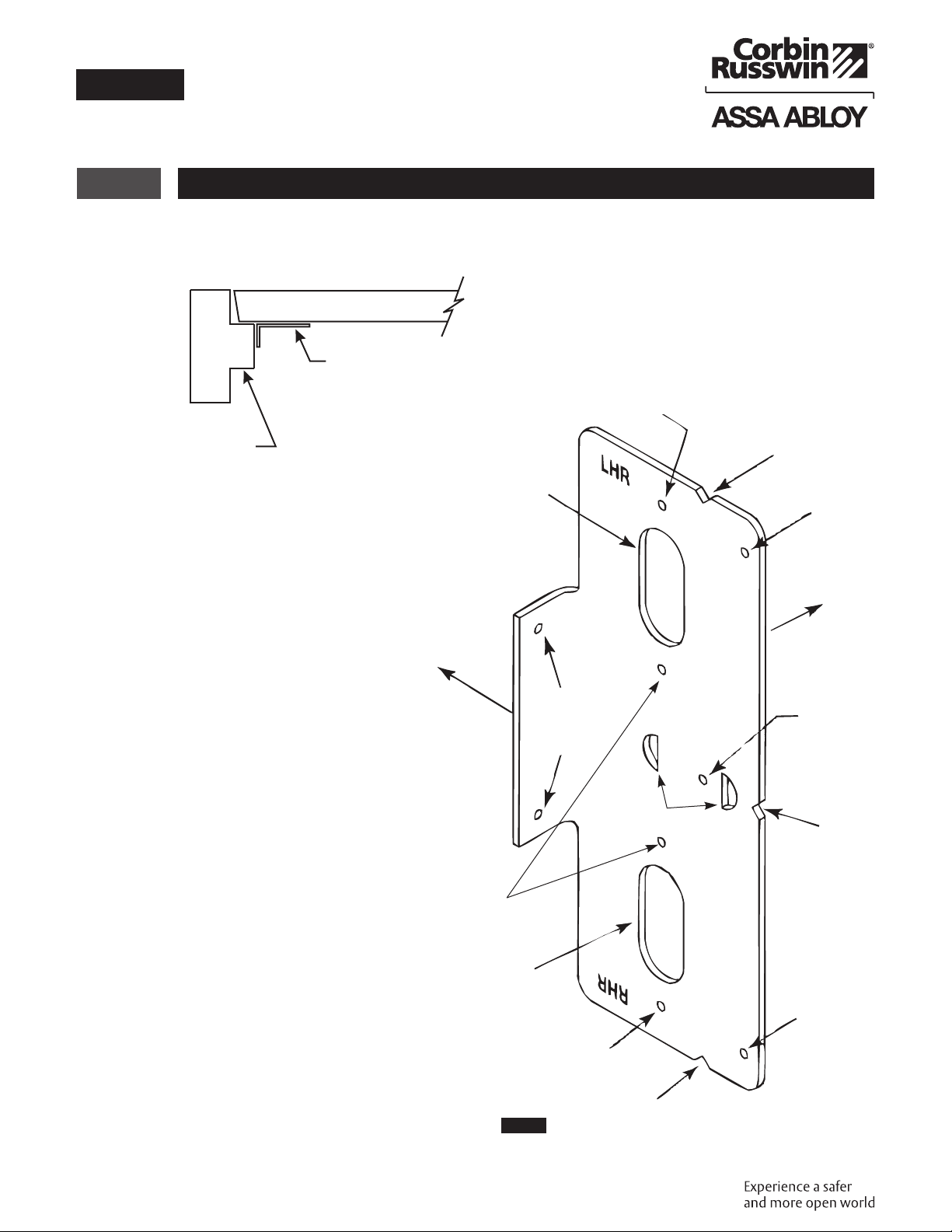

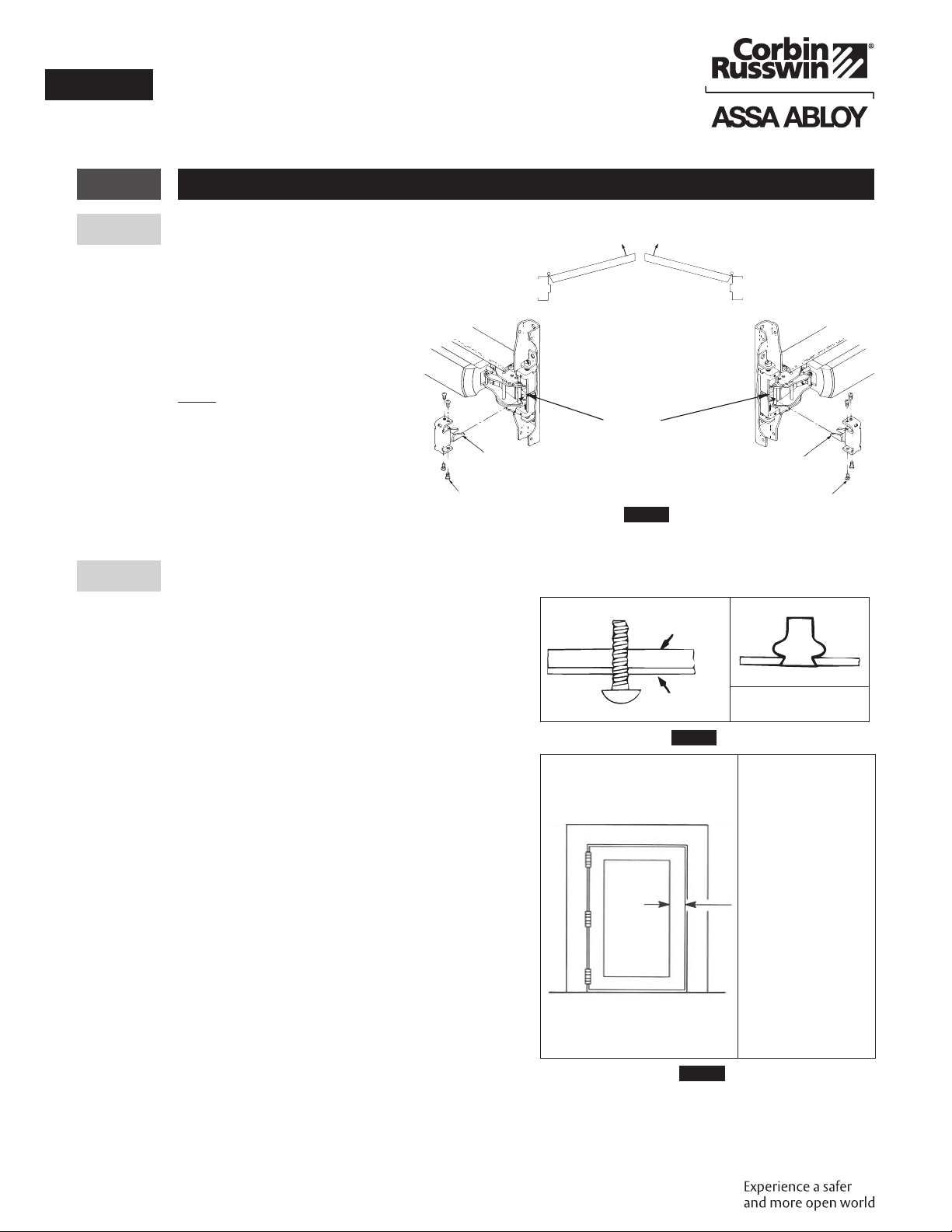

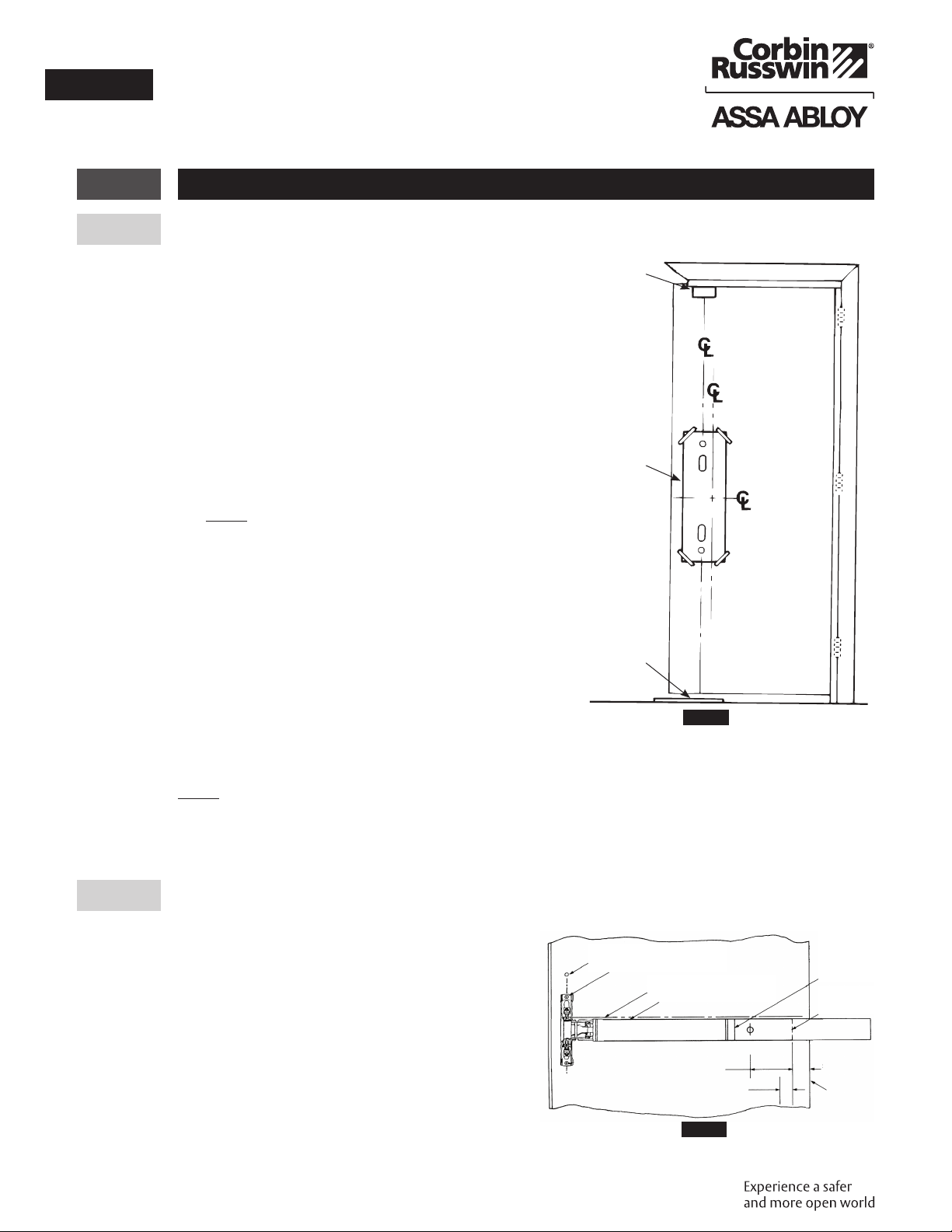

e Size Device

Device must be field cut to size, unless standard

opening and device are 36"(0.91m). (Figure8)

LHR Door Open 90˚ Inside Face

C

L

Figure8

Align mounting holes in door

with mounting holes in device.

Align horizontal line on door

with edge of device.

Verify that there is

no gap between

end cover &

touch bar prior to

marking cutoff.

Mark cutoff line.

Cut square on line.

Figure7

Centerline Vertical

Reference

Centerline Rods &

Strikes

LHR Door Inside Face

Finished Floor

Centerline

Horizontal

Reference

Top Strike Template

(Mounts on Frame

Rabbet)

Floor Strike Tem-

plate (Mounts on

Finished Floor

Device Paper

Template