condensation. If water freezes in the crevices of the structure, ice can damage the

accessory and lead to its destruction. Therefore, if you intend to use the Correctorin

freezing weather at your own risk, make sure that the environment is dry.

Under all conditions, work with the device should be personally supervised. Before

use, make sure that the accessories and their threads are not damaged and that

they are securely mounted. Never use a defective device.

- 5 -

Technology, design and elements

Tilt Corrector was made with 3D printing technology using carbon !ber reinforced

PET-G plastic. Re!nement with this material signi!cantly strengthens the

construction and on the outside it manifests itself with a characteristic, slightly

rough texture.

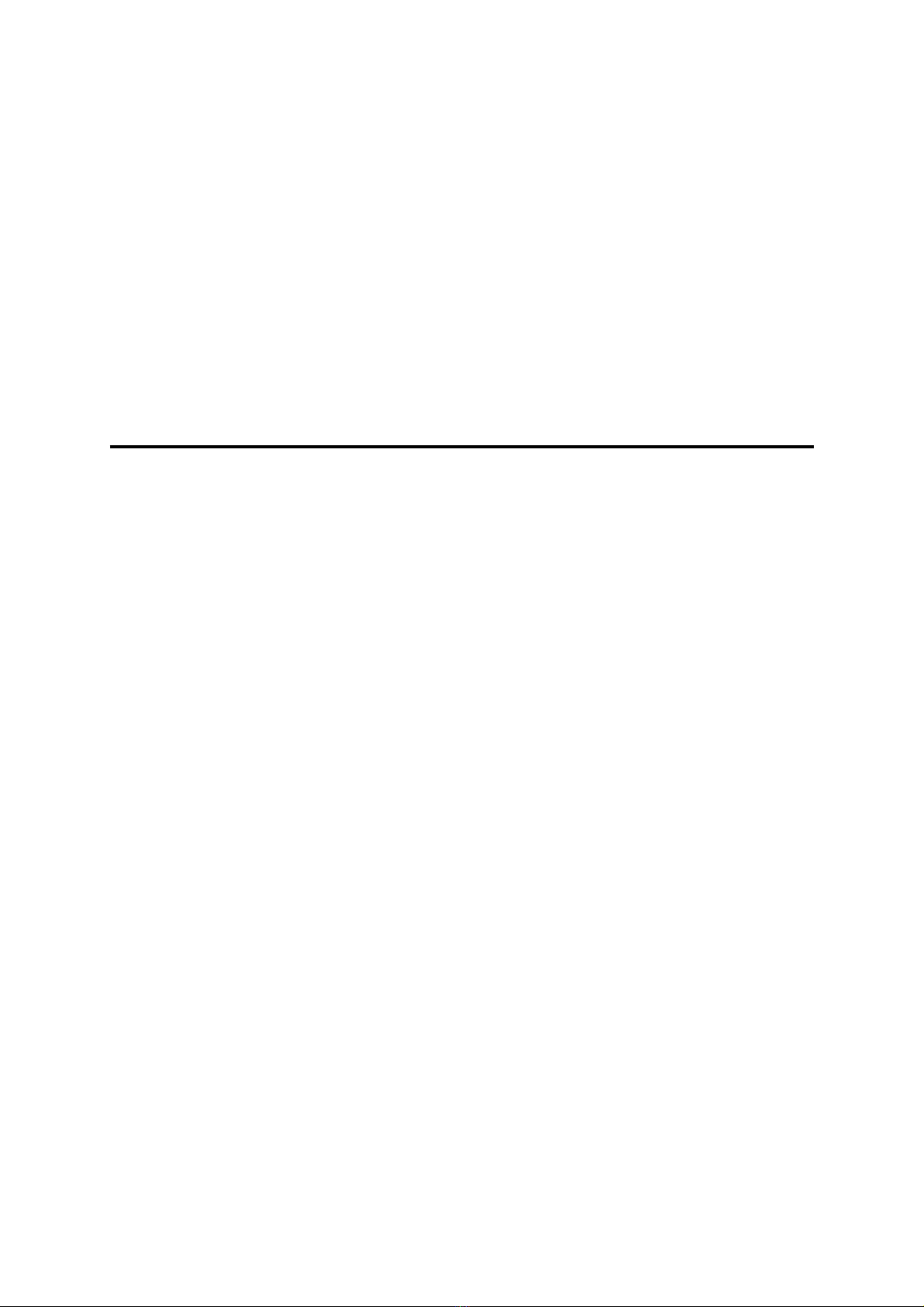

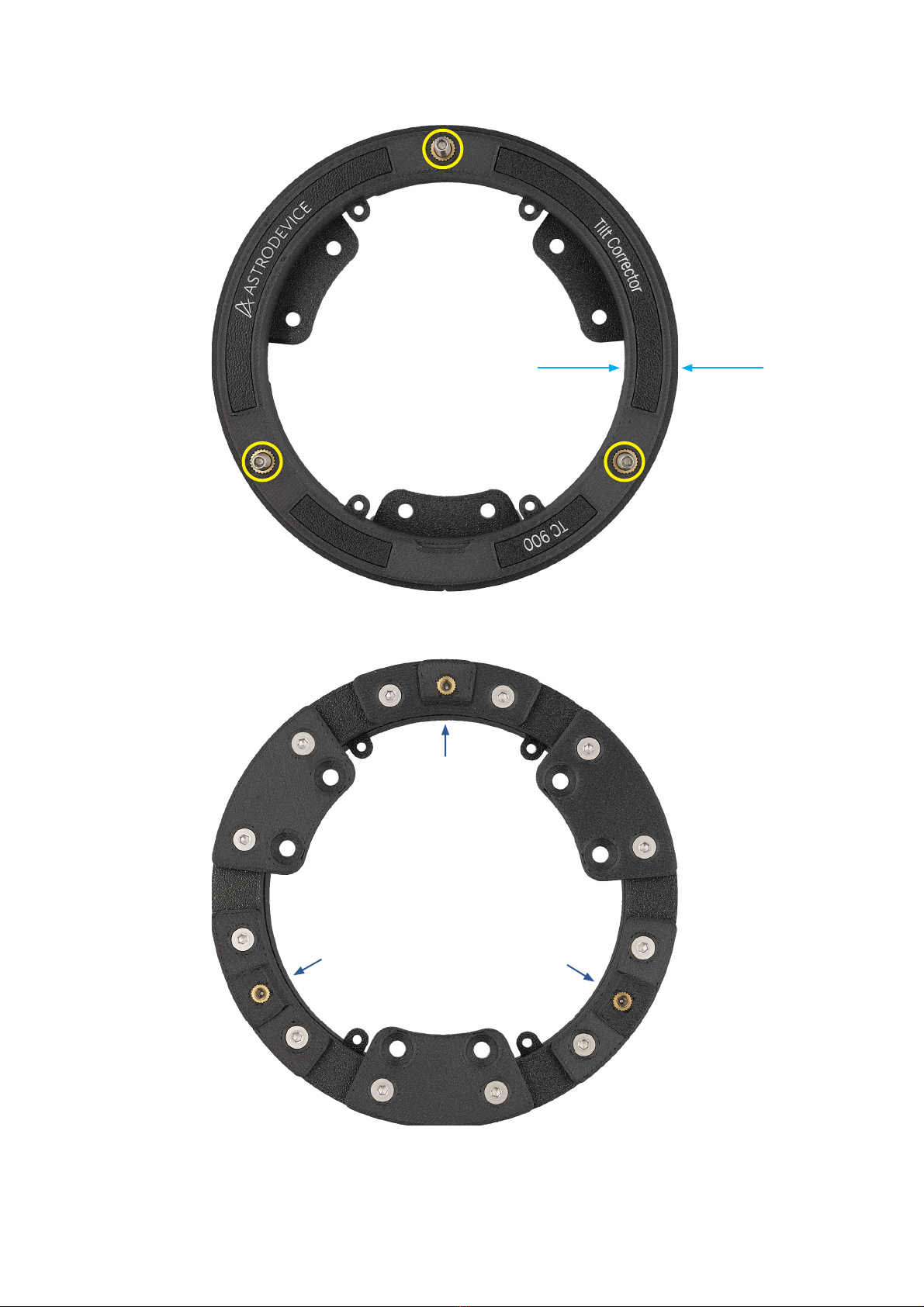

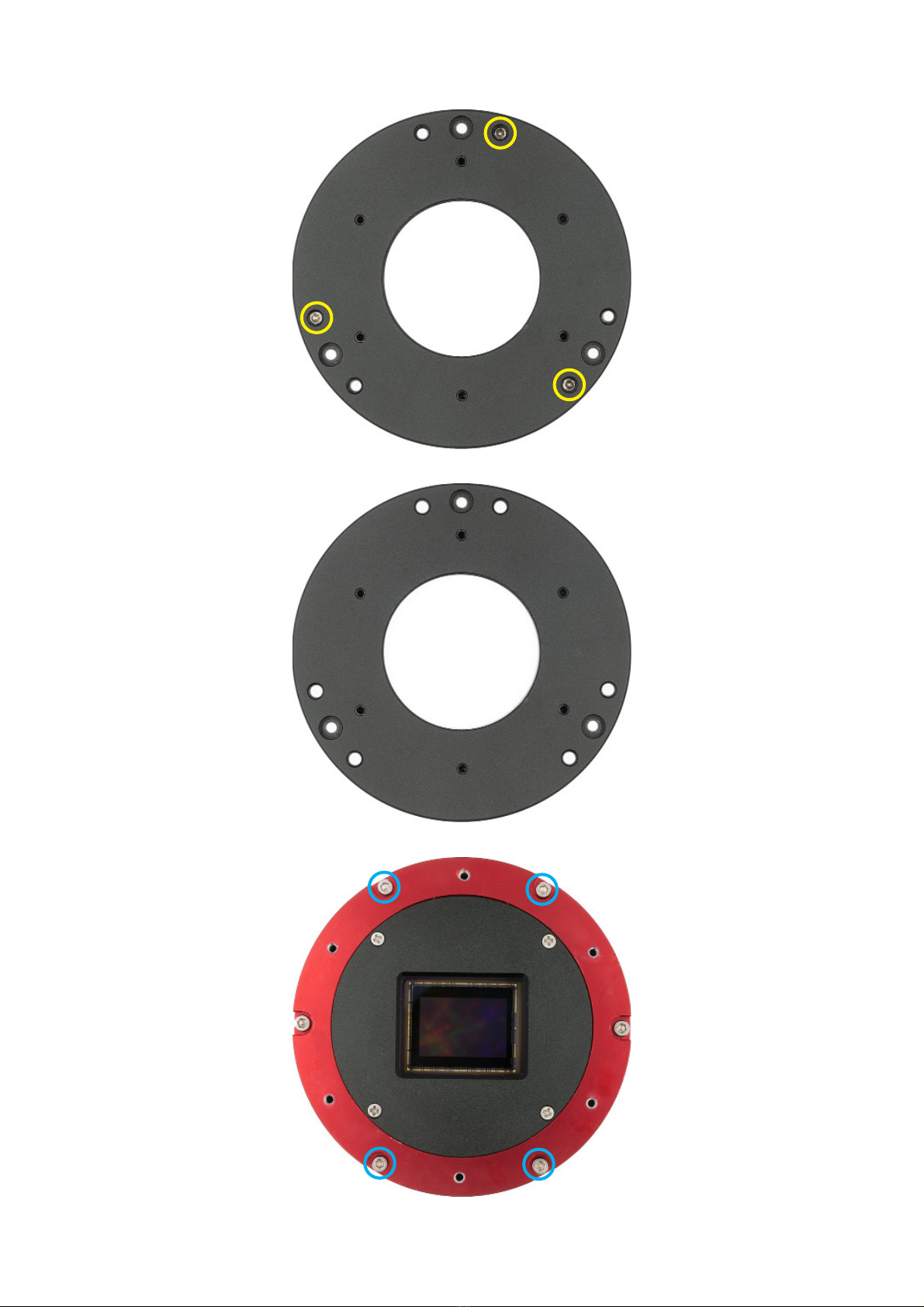

The device consists of two coaxial rings (!g. 1 - R1, R2) connected by three

adjustment screws (S1, S2, S3). The narrower ring, R1, is mounted to the camera

housing through mounting holes H1 - H4. Rotation of screws S1, S2 and S3 pushes

back the wider ring R2, and thus changes the camera’s tilt angle. Clockwise rotation

of the screws moves the planes away from each other, while counterclockwise

rotation brings them closer together. The position where the planes of the rings

touch each other, no adjustment has yet been made, this initial position, will be

referred to as the zero position.

The back of the Tilt Corrector shows 2 groups of components, each of which

consists of three elements arranged around the perimeter every 120 degrees.

In the !rst group there are three bridges B1, B2 and B3 on the center of which there

are adjustment screws BS1, BS2, BS3. The bridges are permanently mounted with

side construction screws marked with a red xmarker. Please do not nor unscrew

these mounting screws, as this may lead to irreparable damage of the drawer.

The second group contains three tabs T1, T2 and T3 for mounting the original tilt