OmniBus II NI PXIe User Manual i

TABLE OF CONTENTS

1. INTRODUCTION .........................................................................................1-1

1.1 OmniBus II Overview ........................................................................................1-1

1.2 OmniBus II Configurations................................................................................ 1-3

1.3 Avionics Databus Protocols...............................................................................1-4

1.4 Other Documentation......................................................................................... 1-5

1.5 Support and Service ...........................................................................................1-5

1.6 Updates...............................................................................................................1-5

1.7 Mean Time Between Failure..............................................................................1-5

2. INSTALLATION........................................................................................... 2-1

2.1 Step 1: Insert the Card into the System .............................................................. 2-1

2.2 Step 2: Install the Driver Software.....................................................................2-2

2.3 Step 3: Set the Card Number and Test the Installation....................................... 2-2

2.4 Step 4: Connect to Databus(s) I/O......................................................................2-3

3. OPERATION................................................................................................3-1

3.1 CoPilot................................................................................................................ 3-1

3.2 User-Developed Software ..................................................................................3-2

4. OMNIBUS II FEATURES ............................................................................ 4-1

4.1 PCI Express Bus.................................................................................................4-1

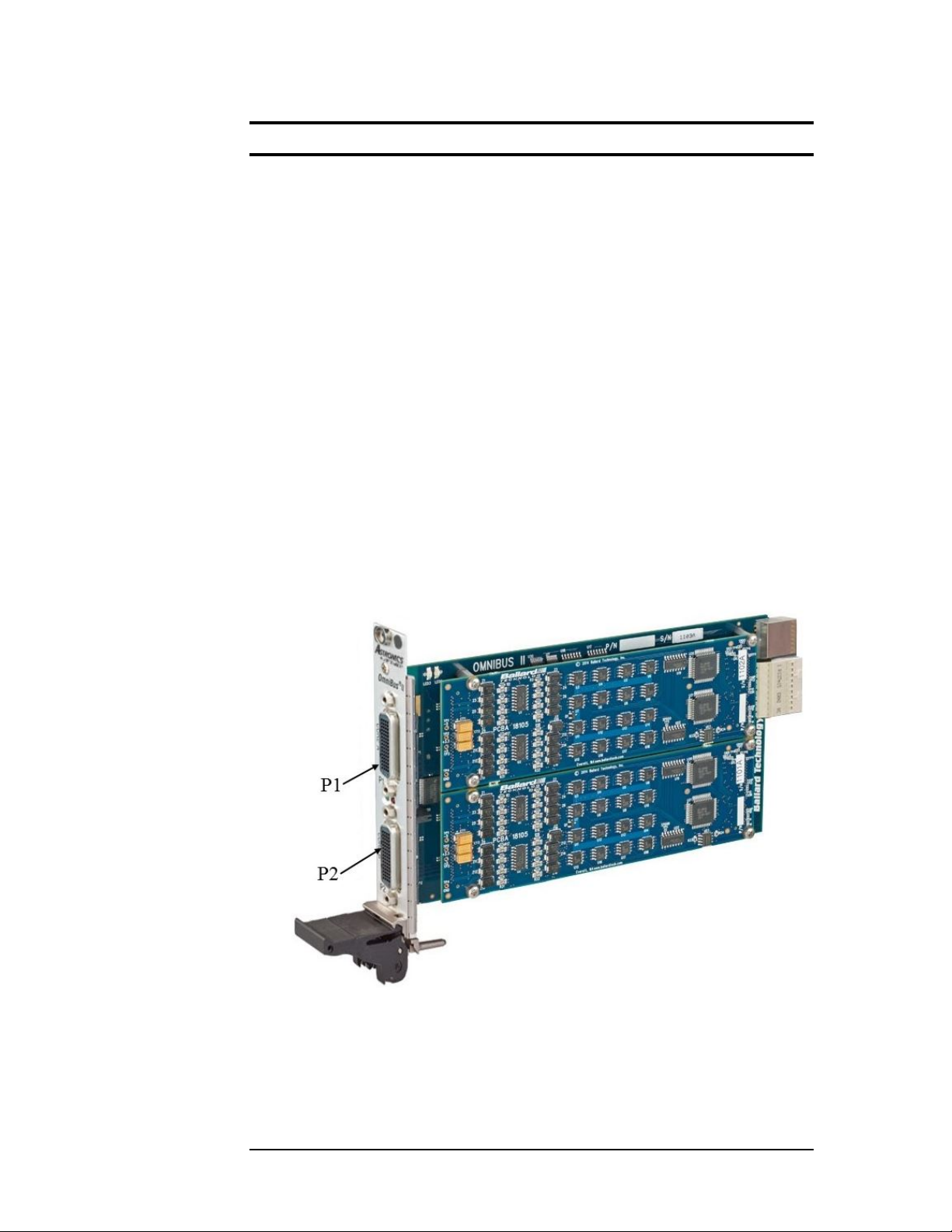

4.1.1 PXIe Form Factor................................................................................ 4-1

4.2 Built-in Test ....................................................................................................... 4-1

4.2.1 Power-on Built-in Test (PBIT)............................................................. 4-1

4.2.2 Initiated Built-in Test (IBIT) ............................................................... 4-1

4.2.3 Continuous Built-in Test (CBIT).......................................................... 4-2

4.3 System Time Synchronization............................................................................4-2

4.3.1 Core Timer.......................................................................................... 4-3

4.3.2 IRIG.................................................................................................... 4-5

4.3.3 PPS..................................................................................................... 4-6

4.3.4 10MHz................................................................................................ 4-7

4.4 Core Discretes....................................................................................................4-7

4.5 1553 Avionics Discretes.....................................................................................4-9

4.5.1 Shunt Inputs........................................................................................ 4-9

4.5.2 Shunt Input Considerations.................................................................4-10

4.5.3 Shunt Outputs.....................................................................................4-10

4.5.4 Shunt Output Considerations ..............................................................4-10

4.5.5 Shunt Discrete Input/Output Usage.....................................................4-12

5. OMNIBUS II PXIE SPECIFIC FEATURES................................................. 5-1

5.1 Clock Switch (CLK SEL)...................................................................................5-1