193-504-121-00 4L25 PAGE 1

SYSTEM INSTALLATION............................................................................................................................................4

RUNNING WIRES INTO THE ENGINE COMPARTMENT............................................................................................ 4

PIN SWITCH INSTALLATION AND WIRING................................................................................................................ 4

TEMPERATURE SENSOR INSTALLATION .................................................................................................................. 5

TACH WIRE CONNECTION ...........................................................................................................................................6

IGNITION COIL TYPES & CONNECTION.....................................................................................................................6

A) STANDARD IGNITION COIL WITH SEPARATE DISTRIBUTOR............................................................................. 6

B) THE MULTICOIL DISTRIBUTORLESS SYSTEM..................................................................................................... 7

C) OTHER MULTICOIL SYSTEMS................................................................................................................................ 7

BRAKE PEDAL CONNECTION ......................................................................................................................................7

CLUTCH SWITCH OVERRIDING...................................................................................................................................8

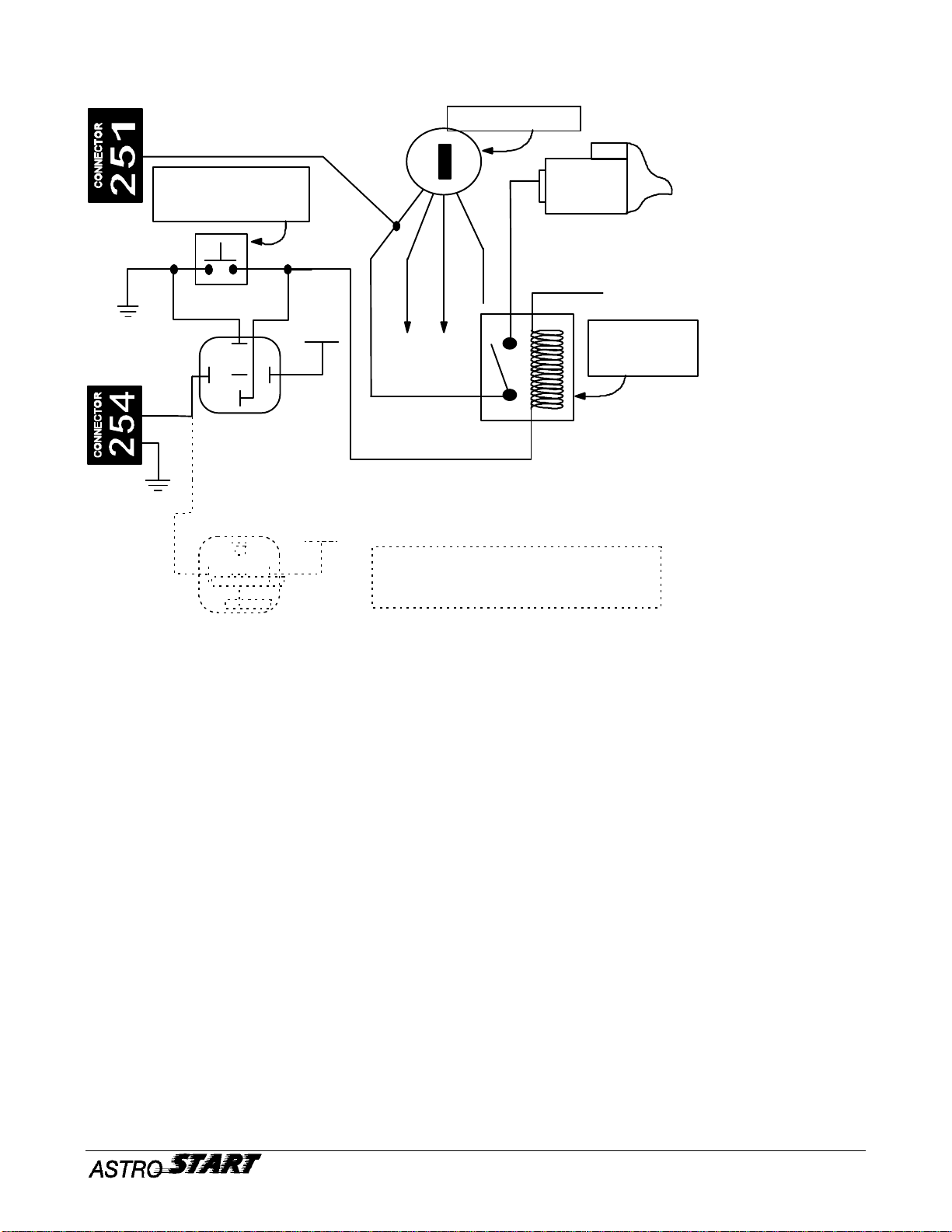

STARTER WIRE SWITCHING .......................................................................................................................................8

STARTER RELAY WIRE SWITCHING...........................................................................................................................9

MAIN HARNESS CONNECTION.................................................................................................................................. 10

MAIN HARNESS TEST.................................................................................................................................................. 11

MAIN HARNESS TROUBLESHOOTING...................................................................................................................... 12

DISABLE SWITCH MOUNTING AND LOCATION ..................................................................................................... 13

INSTALLING THE RECEIVER...................................................................................................................................... 13

MODULE CONNECTION.............................................................................................................................................. 13

SND-1 MODULE INSTALLATION.............................................................................................................................14

HAND BRAKE ............................................................................................................................................................... 14

SENSOR INSTALLATION............................................................................................................................................. 15

RECEIVER INSTALLATION........................................................................................................................................ 15

TRANSMITTER INSTALLATION................................................................................................................................. 16

SENSOR ALIGNMENT................................................................................................................................................ 17

ALIGNMENT VERIFICATION..................................................................................................................................... 18

SYSTEM PROGRAMMING........................................................................................................................................19

PREPARING PRIOR STARTING ................................................................................................................................... 19

MAIN INSTALLATION TEST....................................................................................................................................... 20

TEST AFTER INSTALLATION..................................................................................................................................... 20

MODULE INSTALLATION ........................................................................................................................................... 21

TROUBLESHOOTING ................................................................................................................................................22

START FAIL CODES................................................................................................................................................... 23

RS-504 MODULE........................................................................................................................................................ 23

SND-1 MODULE......................................................................................................................................................... 23

ALARM SYSTEM RS-504............................................................................................................................................ 24

FACTORY DOOR SWITCH INTERFACE ..................................................................................................................... 24

SIREN INSTALLATION ................................................................................................................................................ 25

SHOCK SENSORS.......................................................................................................................................................... 26

INTEGRATED SHOCK SENSOR................................................................................................................................... 26

INTERNAL WARNING BUZZER .................................................................................................................................. 27

ADDITIONAL L.E.D...................................................................................................................................................... 27

OPTIONAL WIRING AND ACCESSORIES...............................................................................................................28

HORN CONNECTION.................................................................................................................................................... 28

REAR WINDOW DEFROSTER ACTIVATION ............................................................................................................. 29

PROTECT INPUT........................................................................................................................................................... 29

DOOR LOCK INTERFACE............................................................................................................................................ 30