INTRODUCTION

Thıs Manual Has Been Prepared For Workshop Personnel Expert In The Use Of The Machıne (Operator) And Technıcıans

Responsıble For Routıne Maıntenance (Maıntenance Fıtter); Read The Manual Before Carryıng Out Any Operatıon Wıth The Rım

Repaır And/Or Packıng . Thıs Manual Contaıns Important Informatıon Regardıng :

Rım Repaır Machınes Safety

He Personnel Safety Of Operators And Maıntenance Workers

CONSERVING THE MANUAL

.

PACKING , TRANSPORT , STORAGE

All packıng,lıftıng , handlıng , transport and unpackıng operatıons are to be performed exclusıvely by expert

personnel wıth knowledge of the rım pres and the contents of thıs manual.

PACKING

Rim Repair machine is crated and stretched on wooden pallet.

LIFTING AND HANDLING

The Pallets Must Be Moved Wıth A Lıft Truck.The Equıpment Chosen Must Be Suıtable For Safe Lıftıng And

Movıng, Bearıng In Mınd The Dımensıons , Weıght , Barycentre , Justs And Fragıle Parts Not To Be Damaged.

STORAGE

Packed Machınery Must Always Be Kept In A Covered , Protected Place At A

Temperature Between –10 C To +40 C And Must Not Be Exposed To Dırect Sunlıght.

OPENING CRATES

When The Crates Arrıve, Check That The Machıne Has Not Been Damaged Durıng Transport And That All The Lısted

Parts Are Present. The Crates Must Be Opened Usıng All Possıble Precautıonary Measures To Avoıd Damagıng The

Machıne Or Its Parts. Make Sure That Parts Do Not Fall From The Crate Durıng Openıng

DISPOSAL OF CRATES

The Wood Of The Pallets And The Strech Fılm May Be Re-Used.

SAFETY

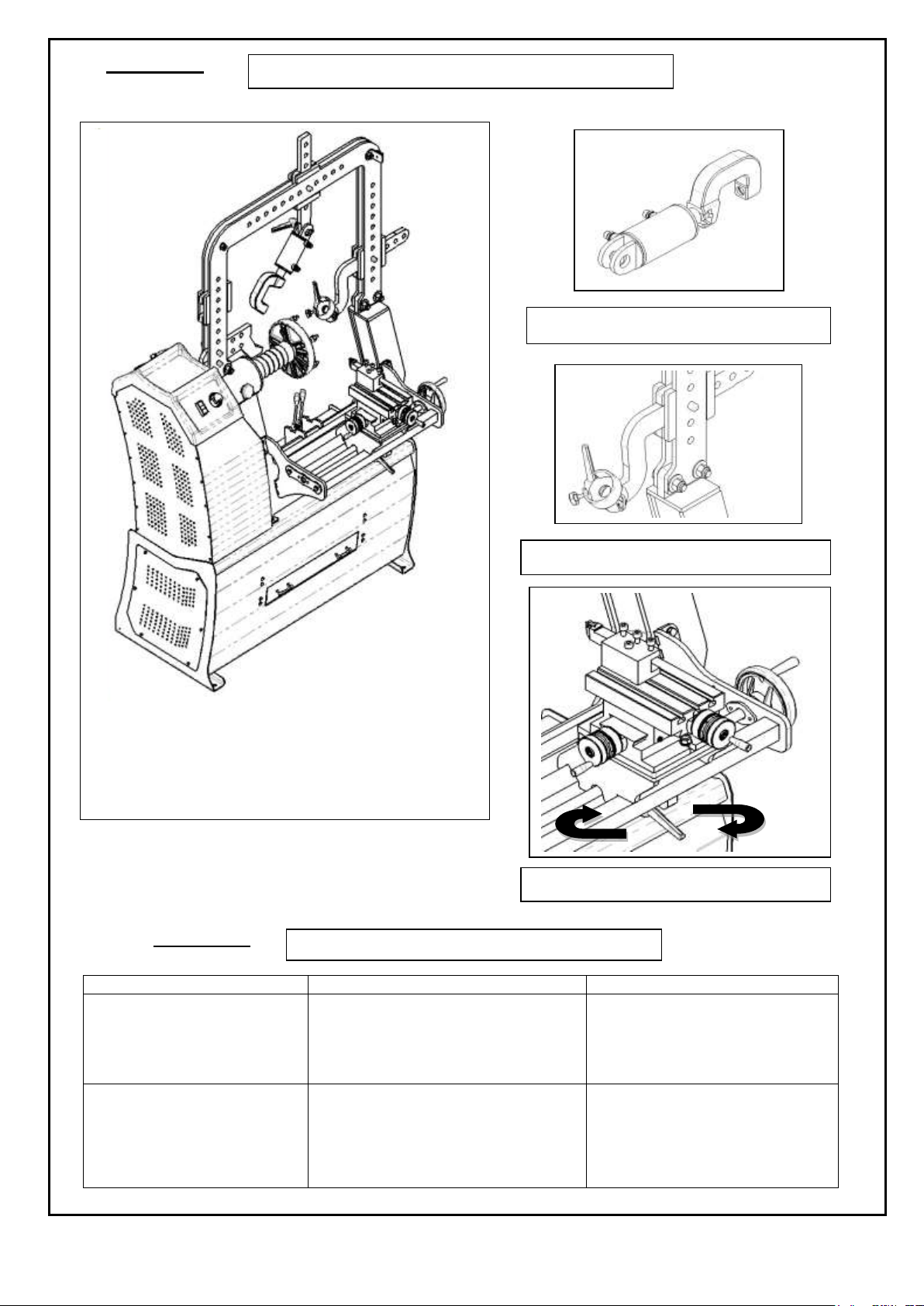

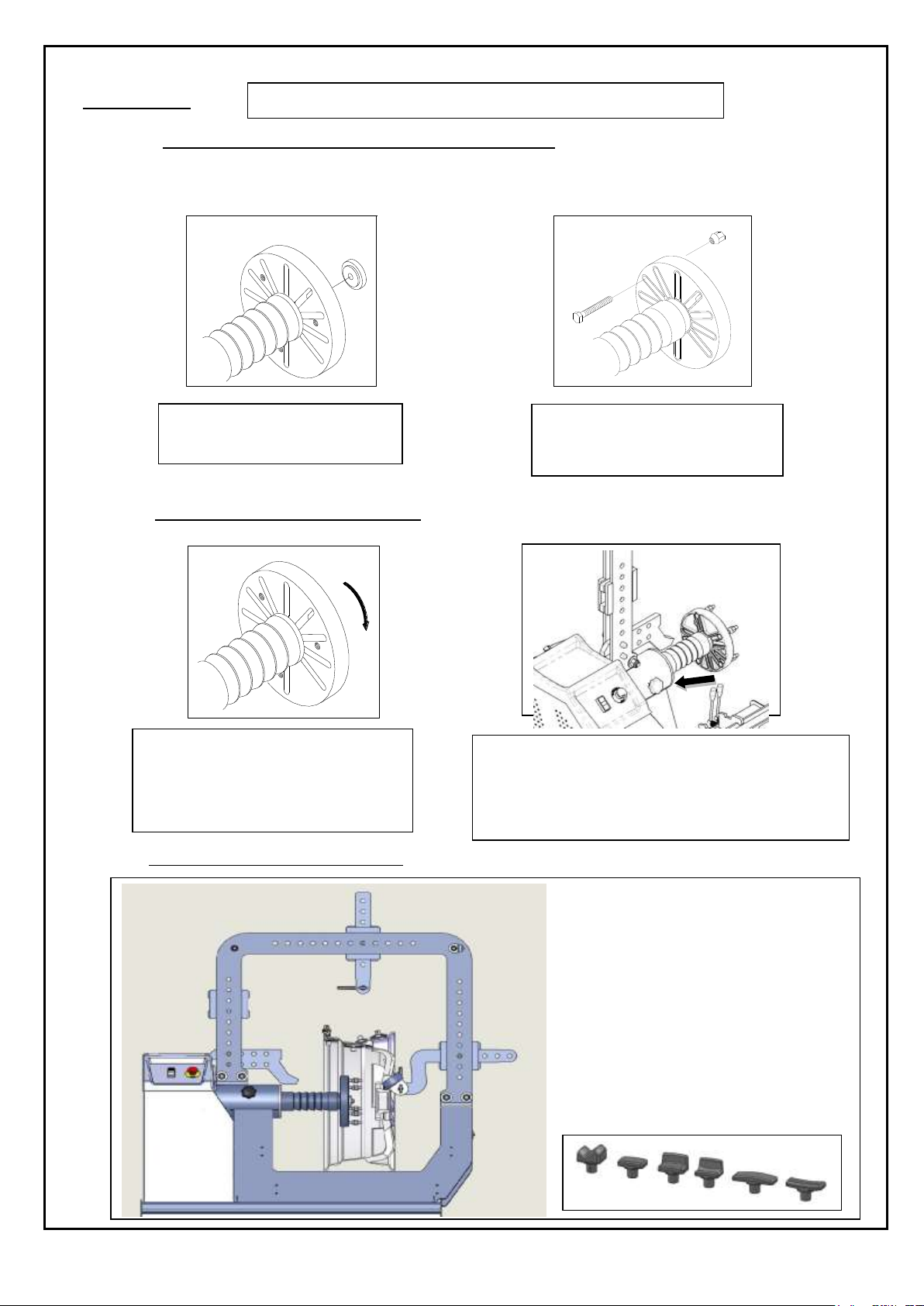

THIS MACHINE IS DESIGNED ONLY FOR 10ıı –26 ıı RIMS.

THIS MACHINE MUST BE USED ONLY FOR RIM REPAIR PROCEDURE.

PAY ATTENTION TO THE WARNING SIGNS ON THE MACHINE.

If the operator hears unusual noises or vibrations or something that may be dangerous , he must immediately press the

emergency button and switch off the main switch and check the section “Malfuctions causes and possible remedies” in

the instructions manual.If the problem is still call the service.

Wear protection glasses and gloves during the operation.

Stand straigth during operation.

Work in an insulated and clean area.

Switch off the main switch when there is no electricity.

Work in the safe distance.

The machine must be fixed onto smooth place.

DO NOT STAND IN FRONT OF THE FLANSH WHEN IT IS ROTATING.

The Manual Is An Integral Part Of The Rım Repaır, Whıch It Should Always Accompany Even If The Unıt Is Sold.

The Manual Must Be Kept In Proxımıty Of The Rım Repaır, In An Easıly Accessıble Place.

The Operator And Maıntenance Staff Must Be Able To Locate And Consult The Manual Quıckly And At Any Tıme.

Lıftıng, Transport , Unpackıng , Assembly , Startıng Up , Inıtıal Adjustment And Testıng , Extraordınary Maıntenance , Repaır ,

Overhauls, Transport And Dısmantlıng Of The Rım Repaır Machıne Must Be Performed By Specıalısed Personnel From The

Lıcensed Dealer Or A Servıce Centre Authorısed By The Manufacturer .

The Manufacturer Declınes All Responsıbılıty For Injury To Persons Or Damage To Vehıcles Or Objects When Any Of The Above

Mentıoned Operatıons Has Been Performed By Unauthorısed Personnel Or When The Rım Repaır Has Been Subject To Improper

Use.

Thıs Manual Indıcates Only The Operatıve And Safety Aspects That May Prove Useful To The Operator And Maıntenance Worker, In

Better Understandıng The Structure And Operatıon Of The Rım Repaır And For Best Use Of The Same.

In Order To Understand The Termınology Used In Thıs Manual, The Operator Must Have Specıfıc Experıence In Workshop, Servıce,

Maıntenance And Repaır Actıvıtıes.