Table of Contents

Safety instructions / Warranty .................................................................................4

GOOD PRACTICES AND SAFETY INSTRUCTIONS............................................................4

AIR QUALITY REQUIREMENTS............................................................................................5

Introduction...............................................................................................................6

ATEQ CDF7000, MULTI-RANGE LEAKAGE CALIBRATOR ...............................................6

FLOW TEST............................................................................................................................6

Measurement principle..................................................................................................6

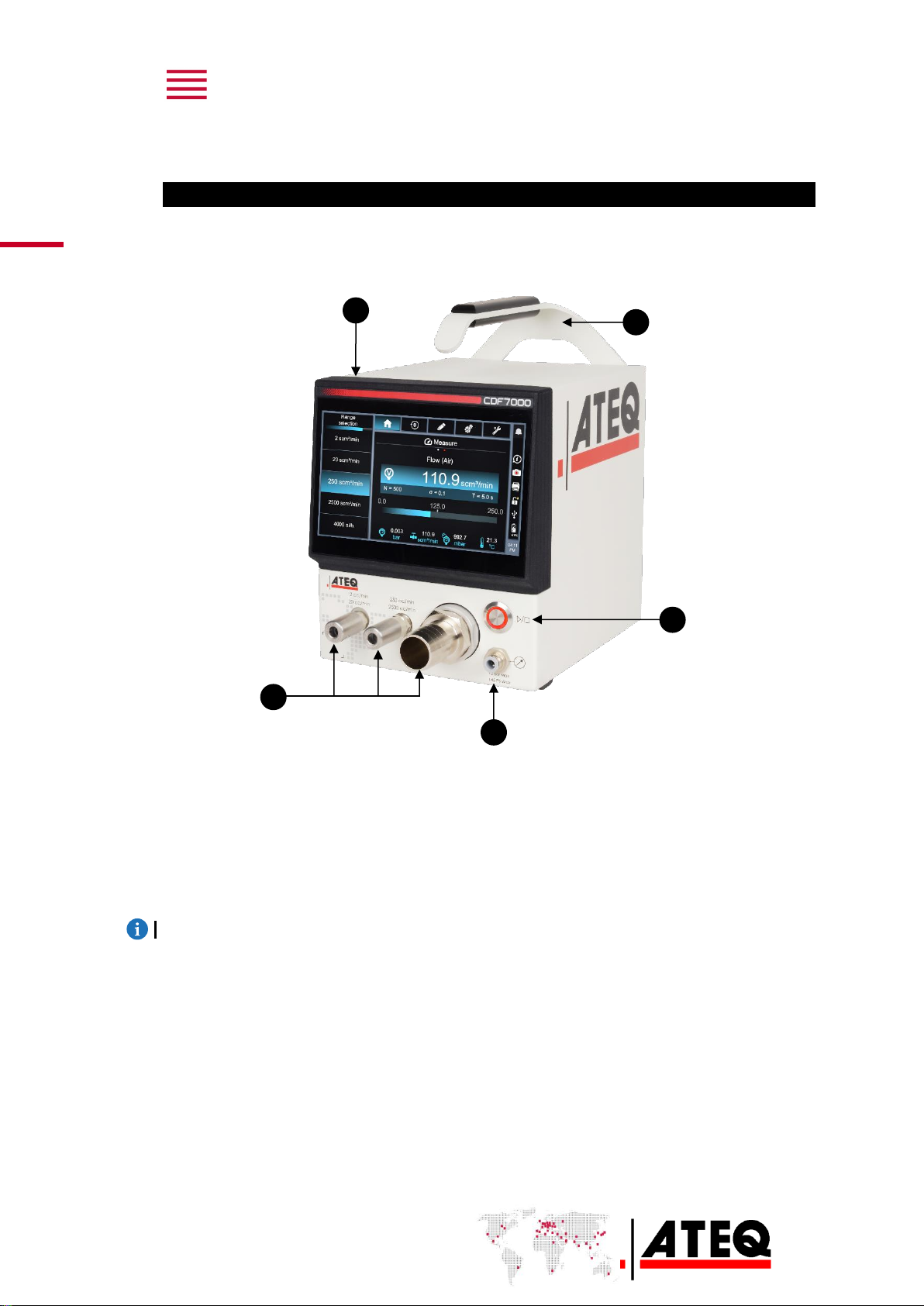

Your ATEQ CDF7000.................................................................................................7

FRONT PANEL .......................................................................................................................7

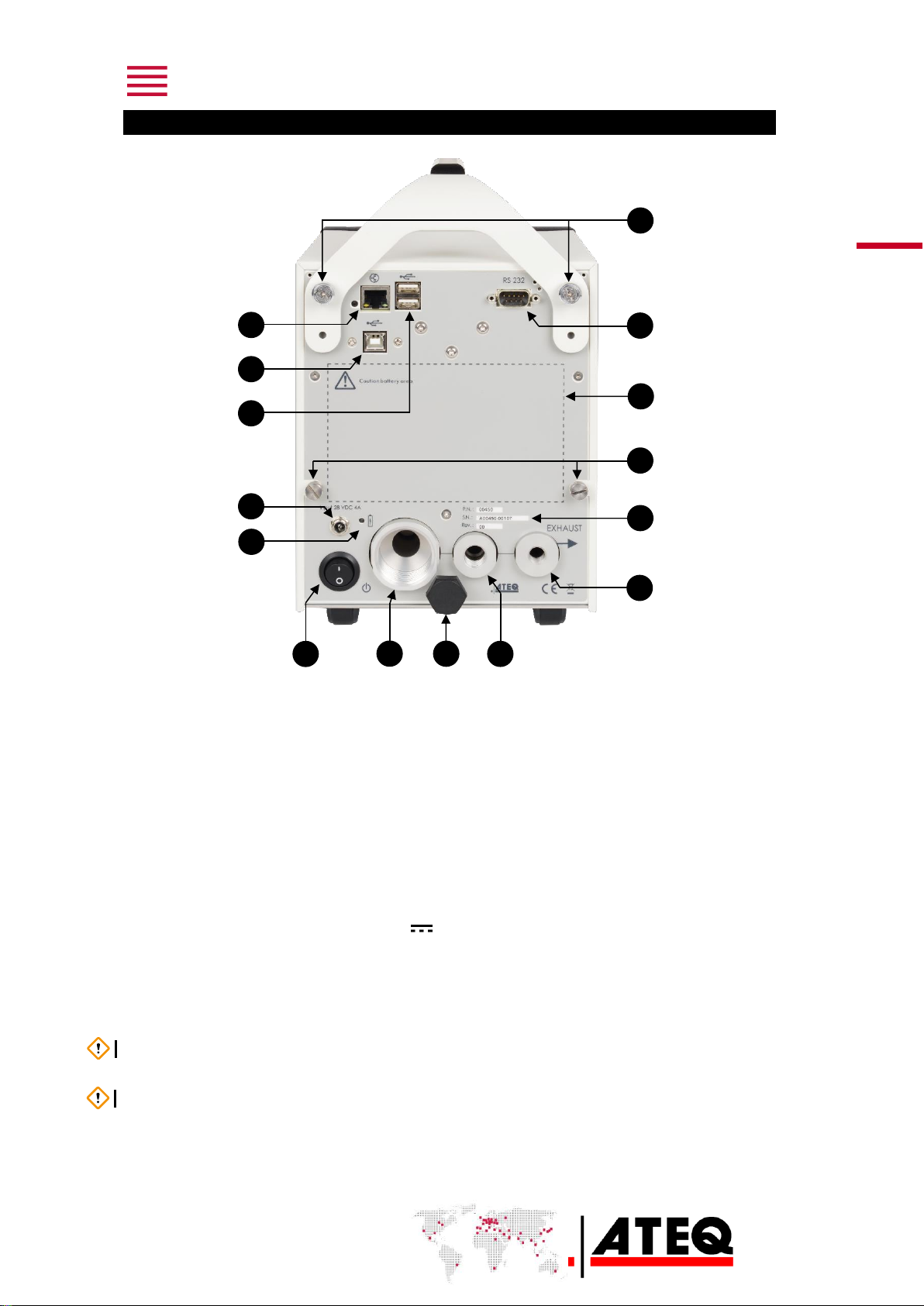

REAR PANEL .........................................................................................................................8

POWER SUPPLY CONNECTOR ...........................................................................................9

External power supply...................................................................................................9

DIGITAL CONNECTIONS.....................................................................................................10

PC USB connector........................................................................................................10

RS232 connector ..........................................................................................................11

Ethernet connector (option).......................................................................................11

PNEUMATIC CONFIGURATION..........................................................................................12

Pressure measurement...............................................................................................12

Leakage measurement................................................................................................12

Leakage calibration......................................................................................................13

User interface..........................................................................................................14

INTRODUCTION ...................................................................................................................14

BUTTON................................................................................................................................14

Cycle button...................................................................................................................14

DISPLAY ...............................................................................................................................15

HOME screen (Standby mode)..................................................................................15

HOME screen (in Measurement mode)...................................................................17

Start-up....................................................................................................................19

POWERING UP.....................................................................................................................19

RANGE SELECTION ............................................................................................................19

STARTING AND STOPPING MEASUREMENTS................................................................20

Starting the measurement..........................................................................................20

Stopping the measurement........................................................................................20

AUTO-ZERO .........................................................................................................................20

User settings...........................................................................................................21

SETTINGS MENU .................................................................................................................21

Available settings.........................................................................................................22