O&M Manual

Rev-P(7/15)2

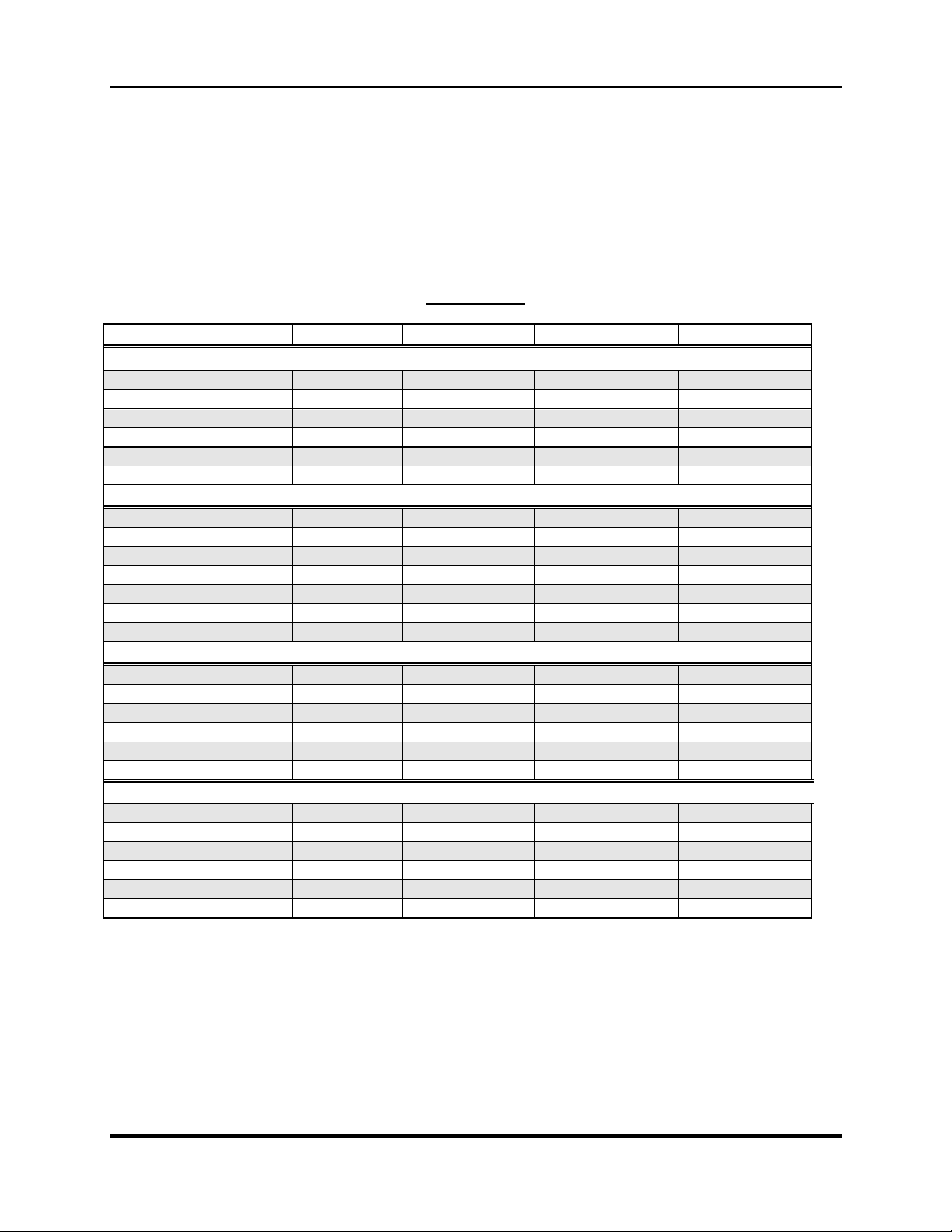

TABLEOFCONTENTS

INTRODUCTION.......................................................................................................................................................4

B12 SENSOR/TRANSMITTER .......................................................................................................................................5

B14 RECEIVER MODULE.............................................................................................................................................5

A17 POWER SUPPLY MODULE....................................................................................................................................5

NEMA 4X ENCLOSURE..............................................................................................................................................5

EXPLOSION-PROOF ENCLOSURES................................................................................................................................5

A UDIBLE HORN ..........................................................................................................................................................6

S TROBE LAMP ............................................................................................................................................................6

A19 BATTERY BACK-UP.............................................................................................................................................6

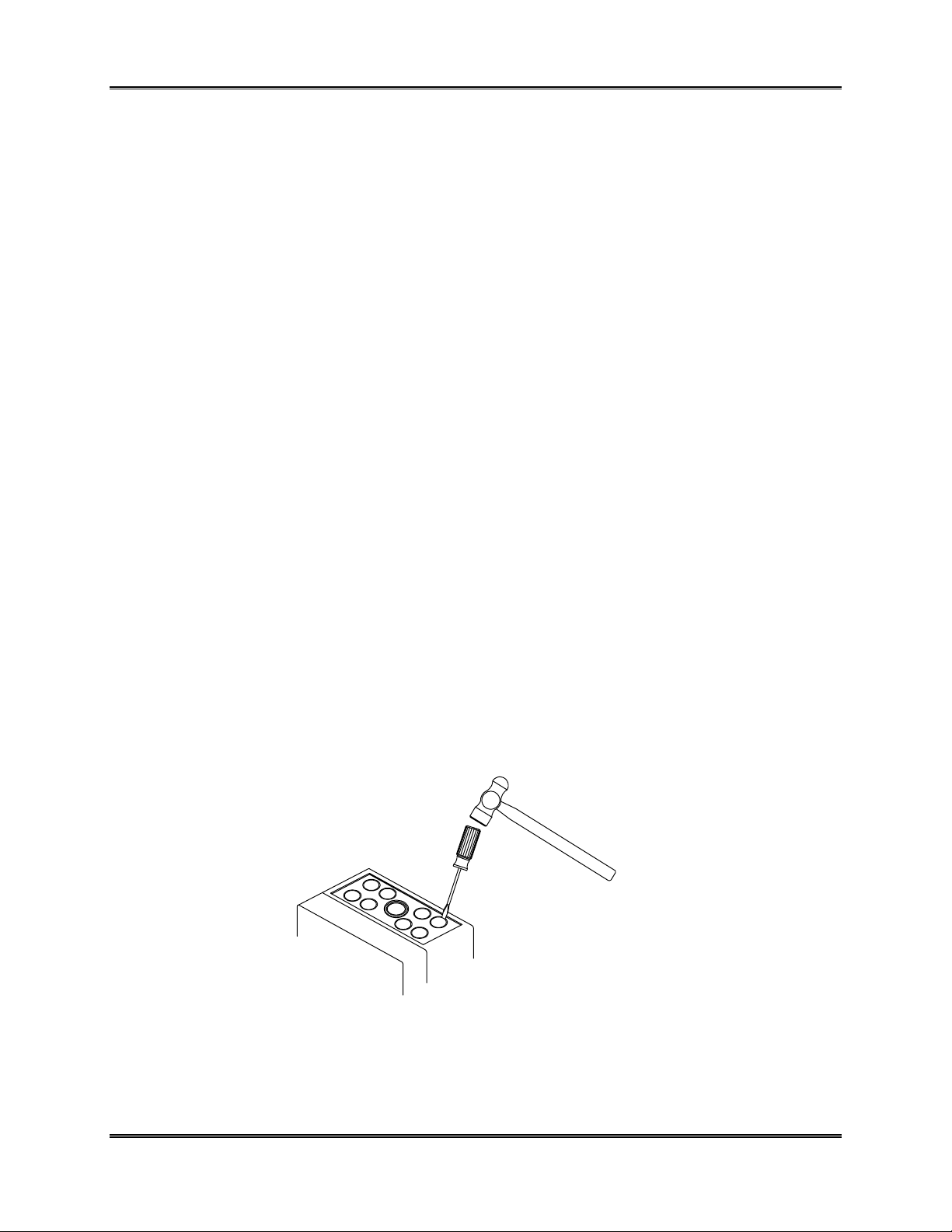

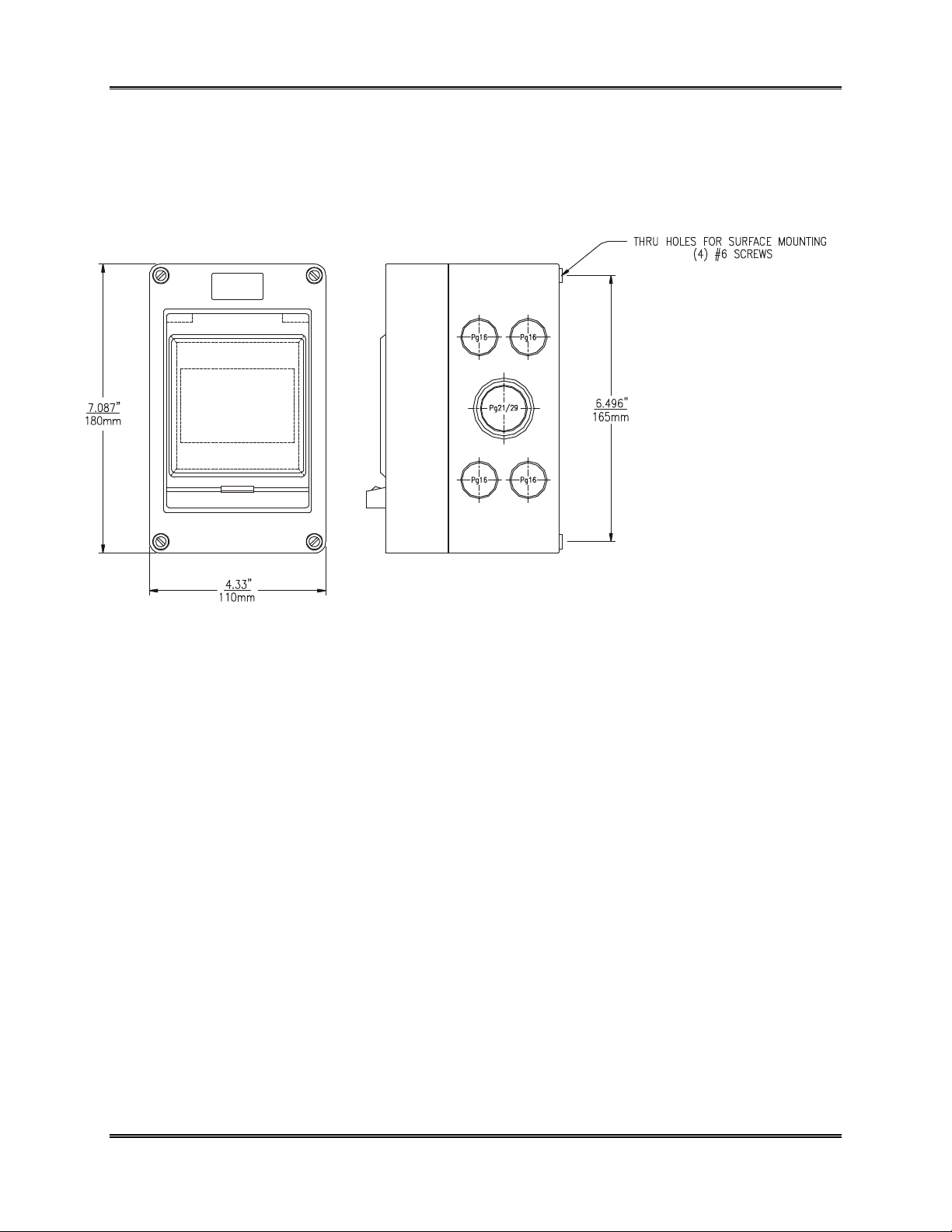

MECHANICALINSTALLATION...........................................................................................................................7

ELECTRICALINSTALLATION..........................................................................................................................12

B14 RECEIVERMODULE.....................................................................................................................................24

ELECTRICAL CONNECTION .......................................................................................................................................24

FACTORY CONFIGURATION ......................................................................................................................................26

CONFIGURATION SWITCHES .....................................................................................................................................27

OPERATING RANGE CHART ......................................................................................................................................28

SETPOINT SELECTION ...............................................................................................................................................29

RANGE SELECTION ...................................................................................................................................................30

RELAY CONFIGURATION...........................................................................................................................................30

EXTERNAL HORN RELAY..........................................................................................................................................31

OPERATION.............................................................................................................................................................32

ALARM ACKNOWLEDGEAND RESET ........................................................................................................................32

TROUBLE ALARM AND RELAY..................................................................................................................................33

LAMPAND HORN TEST.............................................................................................................................................33

INHIBIT MODE ..........................................................................................................................................................33

REMOTE RESET.........................................................................................................................................................34

ANALOG OUTPUT .....................................................................................................................................................34

TROUBLESHOOTING..................................................................................................................................................34

RECEIVER MODULE PARTS LIST......................................................................................................................35

UNIVERSALPOWERSUPPLY.............................................................................................................................36

CAUTION ...............................................................................................................................................................36

POWER SUPPLY PARTS LIST.............................................................................................................................38

BATTERY BACK-UP UNIT..................................................................................................................................39

INSTALLATION..........................................................................................................................................................39

OPERATION...............................................................................................................................................................40

REMOVALFROM SERVICE.........................................................................................................................................40

BATTERY BACK-UP PARTS LIST......................................................................................................................41

STROBELIGHT......................................................................................................................................................42

STROBE PARTS LIST............................................................................................................................................43