Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Pinnacle Park

•

1031 Goodworth Drive

•

Apex, NC 27539 USA

•

Tel: +1.919.772.0115

•

Fax: +1.919.772.8259

•

www.ati-ia.com

•

Email: info@ati-ia.com

4

Table of Contents

Foreword.......................................................................................................................................2

How to Reach Us..........................................................................................................................3

Table of Contents .........................................................................................................................4

Glossary........................................................................................................................................5

Definitions.....................................................................................................................................5

1. Safety....................................................................................................................................6

1.1 General...........................................................................................................................................6

1.2 Explanation of Warnings.................................................................................................................6

1.3 Precautions.....................................................................................................................................6

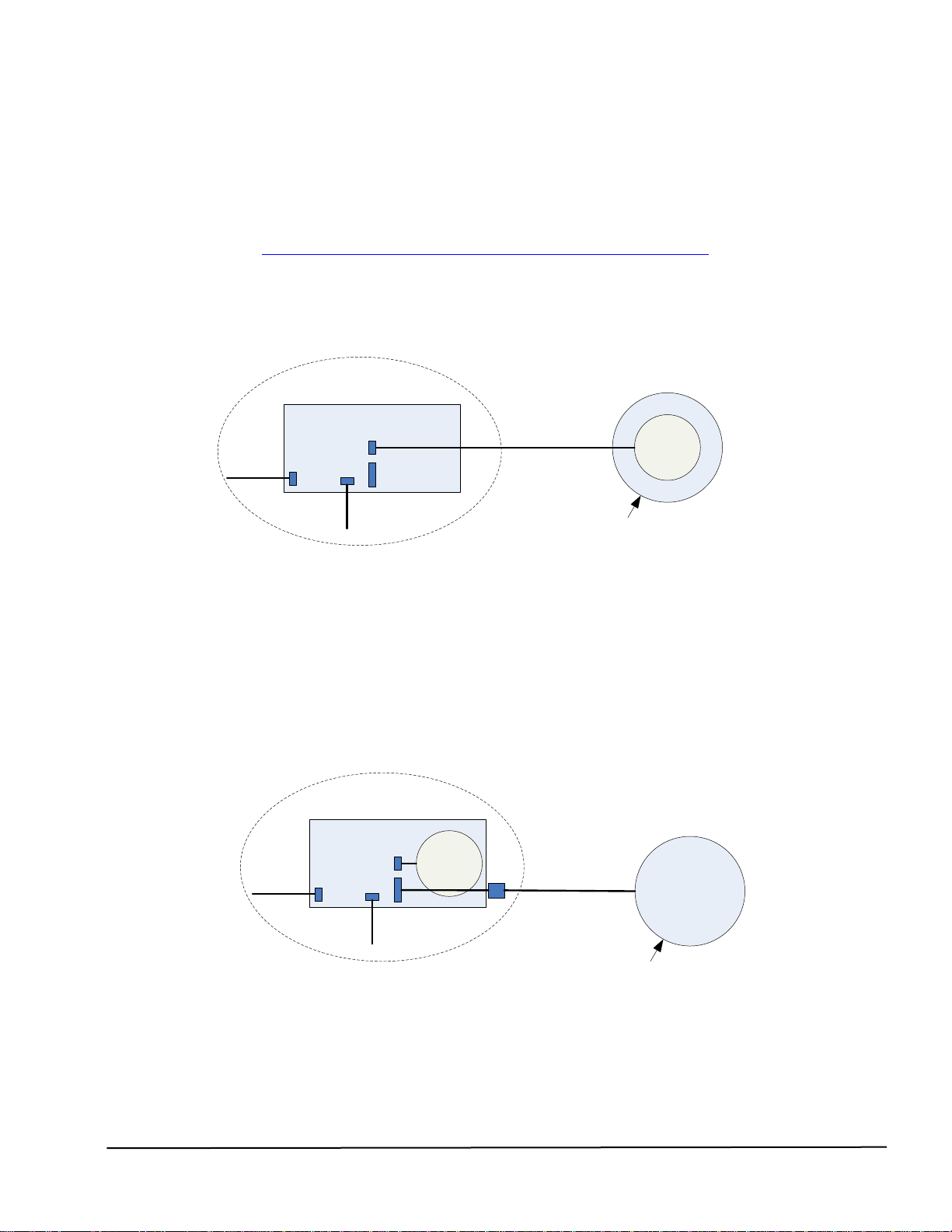

2. System Overview .................................................................................................................7

2.1 NETOEM.........................................................................................................................................7

2.2 NETAOEM......................................................................................................................................7

3. System Components Description.......................................................................................8

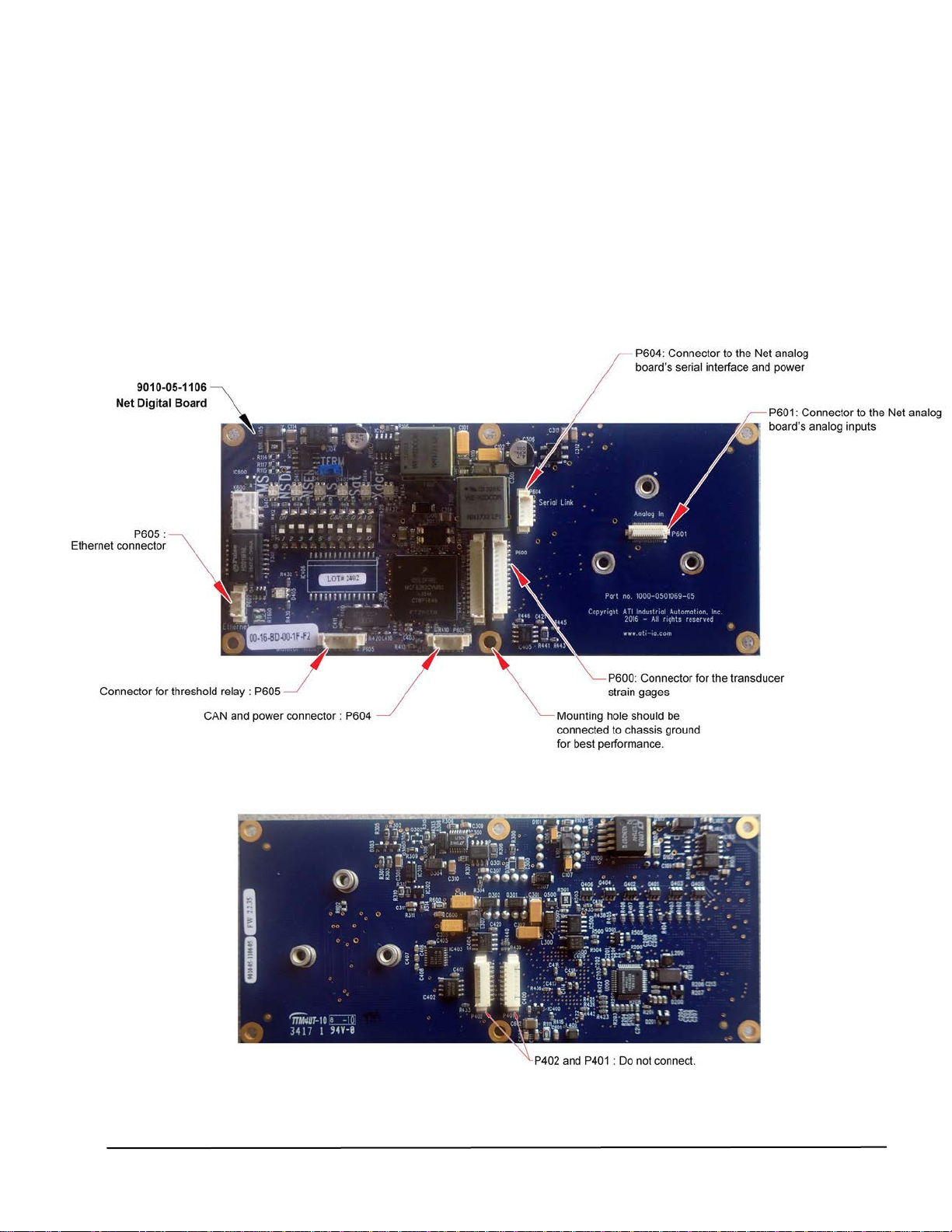

3.1 9010-05-1106 Net Digital Board.....................................................................................................8

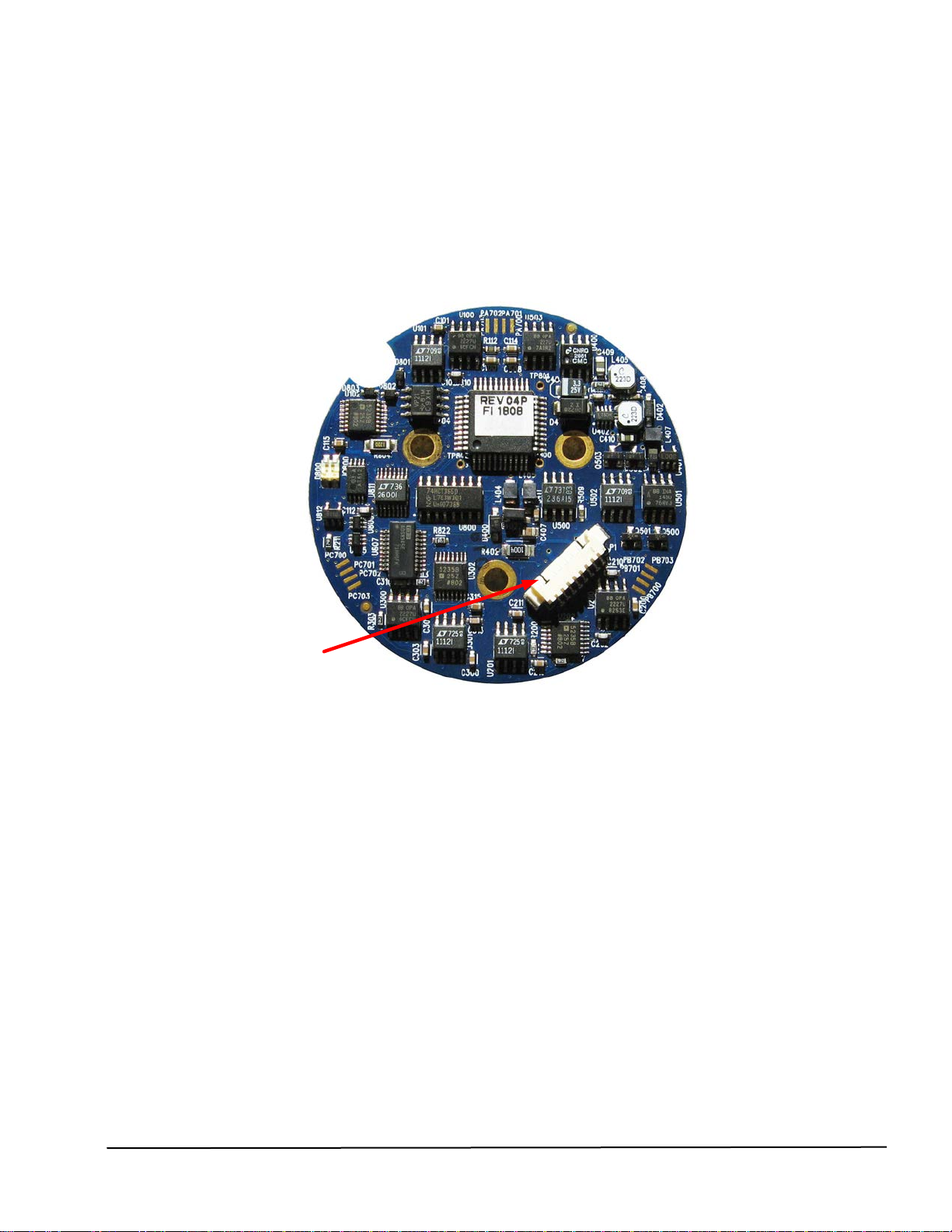

3.2 9010-05-1107 Net Analog Board....................................................................................................9

4. Connectors.........................................................................................................................11

4.1 Net Digital Board connections ......................................................................................................11

4.1.1 P600 Transducer Strain Gage Connector......................................................................11

4.1.2 P602 Ethernet Connector...............................................................................................11

4.1.3 P603 CAN and DC Power Supply Input Connector .......................................................12

4.1.4 P604 Transducer Serial Interface Connector.................................................................12

4.1.5P605 Threshold Relay Connector ..................................................................................12

4.2 Net Analog Board connections.....................................................................................................13

4.2.1 P1 Serial Interface and Power Connector......................................................................13

5. Optional Wire Harnesses...................................................................................................14

5.1 9700-0500005-04 NETAOEM Transducer Strain Gage Wire Harness........................................14

5.2 9000-05-1050 M12-4 Type D Ethernet Wire Harness..................................................................14

5.3 9000-05-1051 M12 Power/CAN Wire Harness.............................................................................15

5.4 9000-05-1052 NETOEM Transducer Wire Harness.....................................................................16

5.5 9000-05-1053 Threshold Relay Wire Harness.............................................................................17

6. Specifications.....................................................................................................................18

6.1 Storage and Operating Conditions ...............................................................................................18

6.1.1 Temperature ...................................................................................................................18

6.2 Electrical Specifications................................................................................................................18

6.2.1 Power Supply..................................................................................................................18

6.2.2 Threshold Relay..............................................................................................................18

6.3 Weights and Dimensions..............................................................................................................18

7. Drawings.............................................................................................................................19

7.1 9230-05-1372 Net Digital and Analog Board Drawing .................................................................19

8. Terms and Conditions of Sale...........................................................................................20