Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 USA• Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

3

Table of Contents

Foreword.......................................................................................................................................... 2

Glossary........................................................................................................................................... 5

1. Safety......................................................................................................................................... 6

1.1 ExplanationofNotications.........................................................................................................6

1.2 General Safety Guidelines............................................................................................................6

1.3 Safety Precautions........................................................................................................................6

2. Product Overview..................................................................................................................... 7

2.1 FFP..................................................................................................................................................8

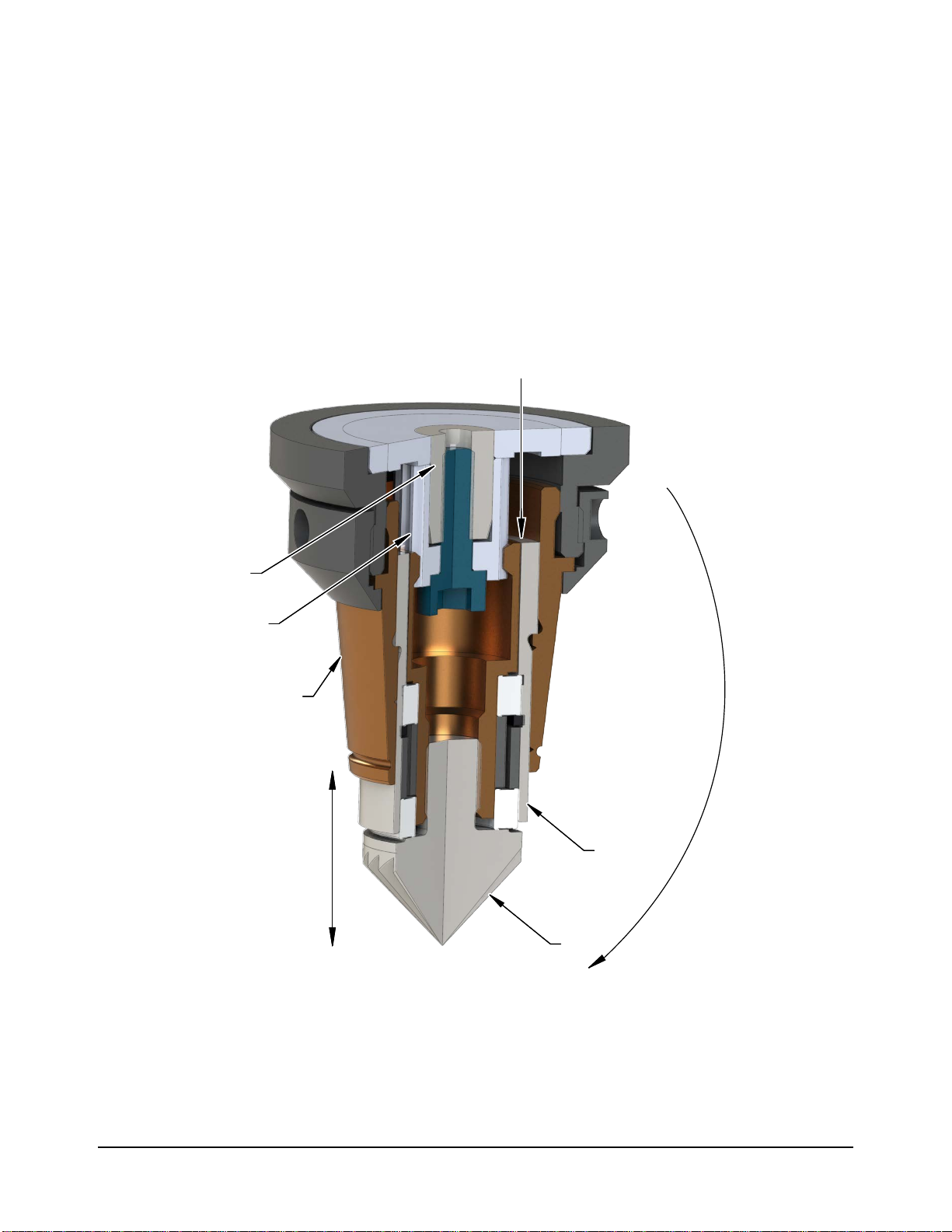

2.2 Technical Description ...................................................................................................................9

2.2.1 Environmental Limitations..................................................................................................9

2.2.1.1 Operation............................................................................................................9

2.2.1.2 Storage...............................................................................................................9

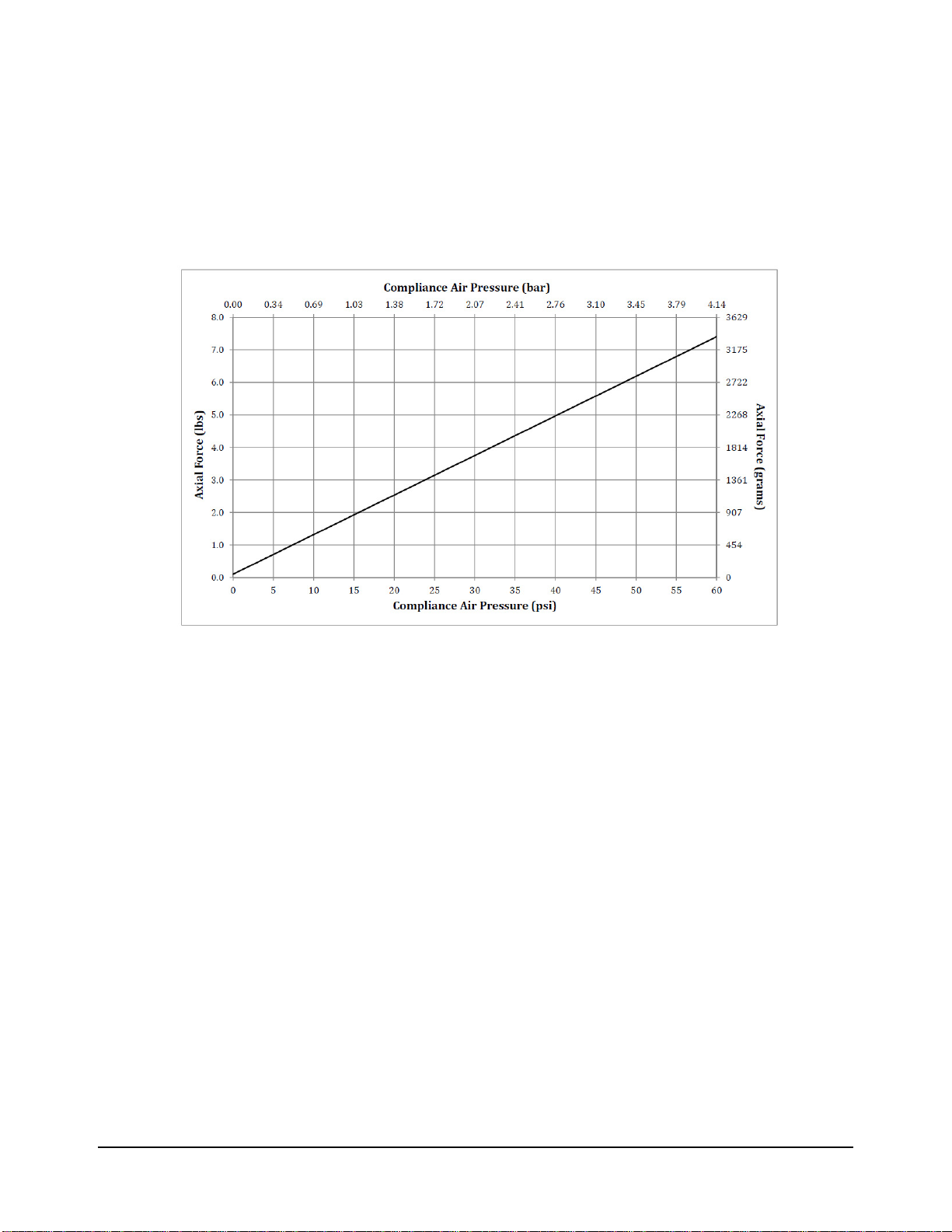

2.2.2 Axial Force/ Compliance Unit Performance .....................................................................10

2.2.3 Air Motor Performance..................................................................................................... 11

3. Installation .............................................................................................................................. 12

3.1 Protection During Transportation..............................................................................................12

3.2 Inspection of Condition When Delivered..................................................................................12

3.3 Unpacking and Handling............................................................................................................12

3.4 Storage and Preventive Maintenance During Storage.............................................................12

3.5 Mounting Installation..................................................................................................................13

3.6 Pneumatics..................................................................................................................................14

4. Operation ................................................................................................................................ 16

4.1 Safety Precautions......................................................................................................................16

4.2 Normal Operation........................................................................................................................17

4.2.1 Air Quality.........................................................................................................................17

4.2.2 Lubrication........................................................................................................................17

4.2.3 Media Selection, Design, and Maintenance.....................................................................17

4.2.4 Deburring Tool Approach Path Should Be Slow and At an Angle.....................................17

4.2.5 No Radial Loading............................................................................................................17

4.2.6 Program the Robot to Incorporate 50% Compliance Travel of the Tool ...........................17

4.3 Speedeburr Working Environment............................................................................................18

4.4 Tool Center Point (TCP) Position...............................................................................................18

4.5 Programming the Deburring Tool Path .....................................................................................18

4.6 Cutter Operation and Burr Selection.........................................................................................19

4.6.1 Bur Selection....................................................................................................................19