10 TETRIX by Pitsco 39132 V0909

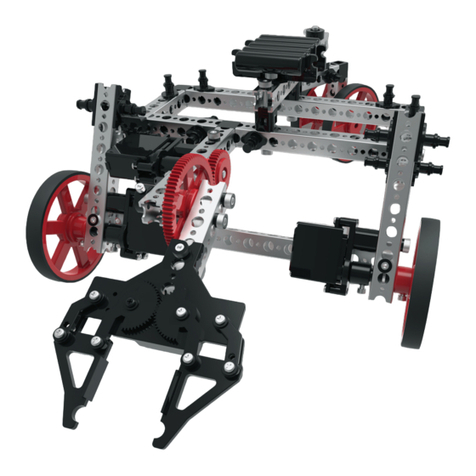

2) Find the pivot bearing, screw, nut, and washer

that comes with the pivot bracket. Place the bear-

ing ange-side down on a at surface. Place the

side of the pivot bracket opposite the horn over

the bearing and align the bracket hole to it (Figure

B5a). Press down rmly to pop the bearing into

the bracket hole (Figure B5b).

3) Place the bearing screw through the bearing from

the outside of the pivot bracket. Insert the screw

into the back of the motor bracket (Figure B6).

Secure the pieces together with the washer and

nut – but do not overtighten.

4) Place the servo into the motor bracket,

stretching the unattached side of the pivot

bracket so the horn ts into the

servo’s motor shaft. Secure the

servo to the motor bracket with

3/8" BHCSs (Figure B7).

5) Adjust the servo’s range of mo-

tion as needed (see TETRIX Tip

on this page). Thread the servo

horn screw through the pivot

bracket and horn and secure to

the servo.

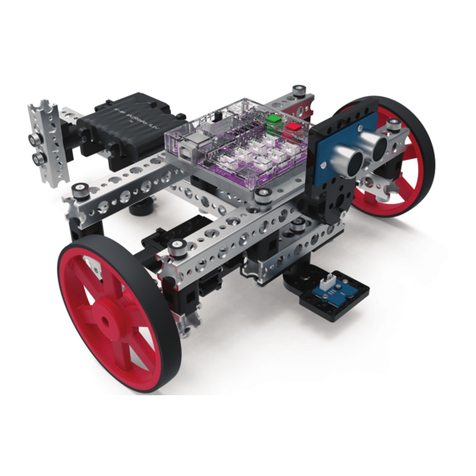

Double-Servo Mount

and Pivot

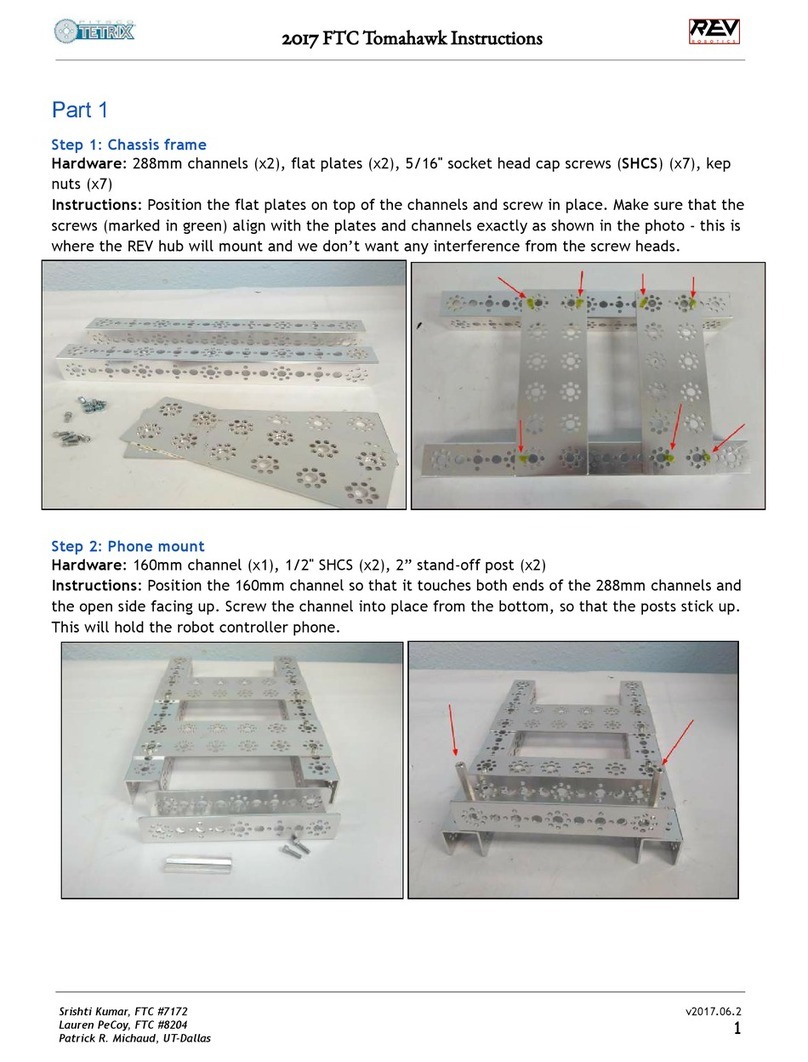

1) Determine where on the chas-

sis you want to place the servos.

Using 1/2" SHCSs and kep nuts,

attach the double-servo motor

bracket to the chassis

(Figure B8).

2) Remove servo horns from two

servos. Attach these to a joint

pivot bracket – each with two

5/16" SHCSs and kep nuts –

so one is on the inside of the

bracket and the other is on the

outside and opposite end

(Figure B9).

Figure B6 Figure B7

Figure B8 Figure B9

Figure B5a Figure B5b

TETRIX Tip: Range of Motion

To adjust a servo’s range of motion, you must rst nd its mechanical stop.

Push the bracket or structural element attached to the servo until it won’t

go any further – this is the mechanical stop. Without moving the servo mo-

tor shaft, detach the bracket or element and position it where you want it to

stop. Reattach it to the servo, taking care not to move the servo motor shaft.

Secure the bracket or element to the servo with the servo horn screw.