9 Rev. 00

1 HOW TO USE AND KEEP THIS INSTRUCTIONS

HANDBOOK

1.1 Purpose and Allocation of these Instructions

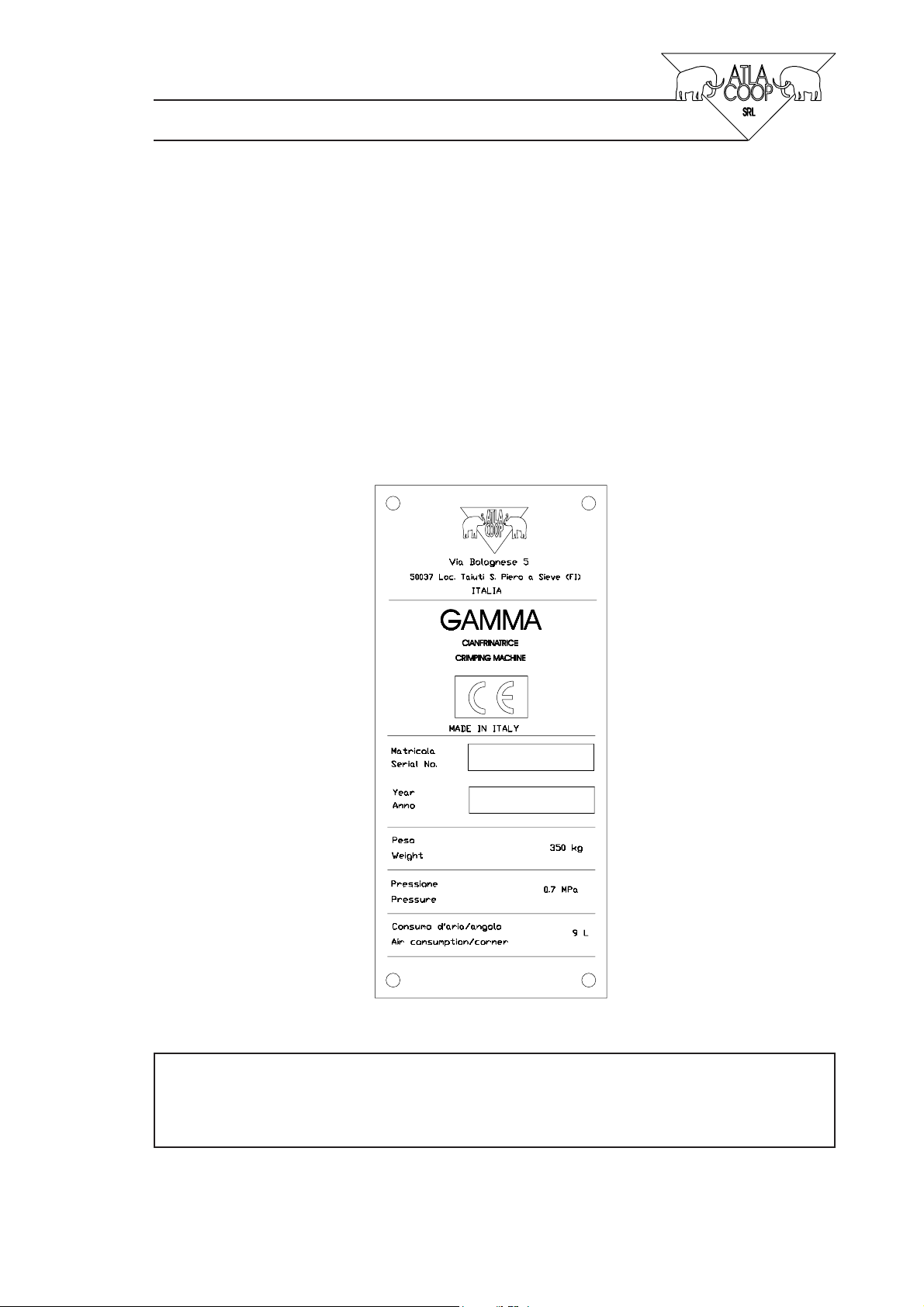

This Instructions Handbook contains the necessary instructions for the correct use and maintenance

of the pneumatic crimping machine called GAMMA.

The machine must always be accompanied by these instructions throughout its whole lifetime. In the

event that the machine is sold or given in possession of a third party, it's necessary to transfer also

these instructions together with all the other enclosed documents in order to guarantee the user's and

operator's safety.

This handbook allows to perform the following operations :

— installation

— regulation

— exploitation

— maintenance

— scrapping

This handbook is allocated both to the user and to the operator in charge of these operations. The

failure to use the machine in accordance with the instructions contained in this handbook will release

the company ATLA COOP from any liability.

The company ATLA COOP shall not be liable for incidental or consequential damages resulting

from the following circumstances :

— Abuse or misuse of the machine

— Failure to use the machine in accordance with the technical or safety standards in force in a

given country

— Installation of the machine in a manner inconsistent with the instructions contained in this

handbook

— Failure to perform the forseen maintenance

— Alteration, modification

— Replacement of not original or not specific spare parts

— Failure to use the machine in accordance with the instructions of this handbook

These instructions cannot be used as a point of reference for adaptations, changes or adjustments to

upgrade the machine from its normal purpose. If this happens ATLA COOPshall be released from

any liability. ATLA COOP shall not be liable for circumstances other than defects in materials or

workmanship.